Non-notch semi-continuous process combined step mining method

A technology combining benches and mining methods, applied in open-pit mining, earthwork drilling, special mining, etc., can solve the problem of not meeting the requirements of "three mining and one moving", the limitation of bench height, and the small amount of mining during the transfer period, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

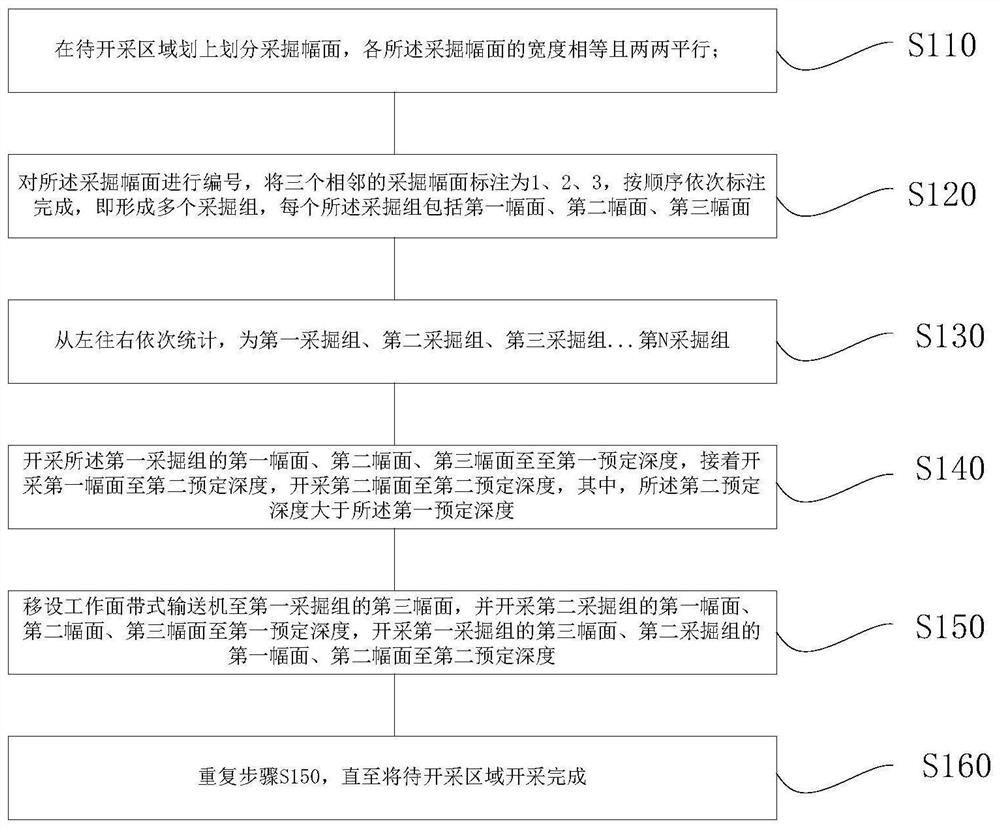

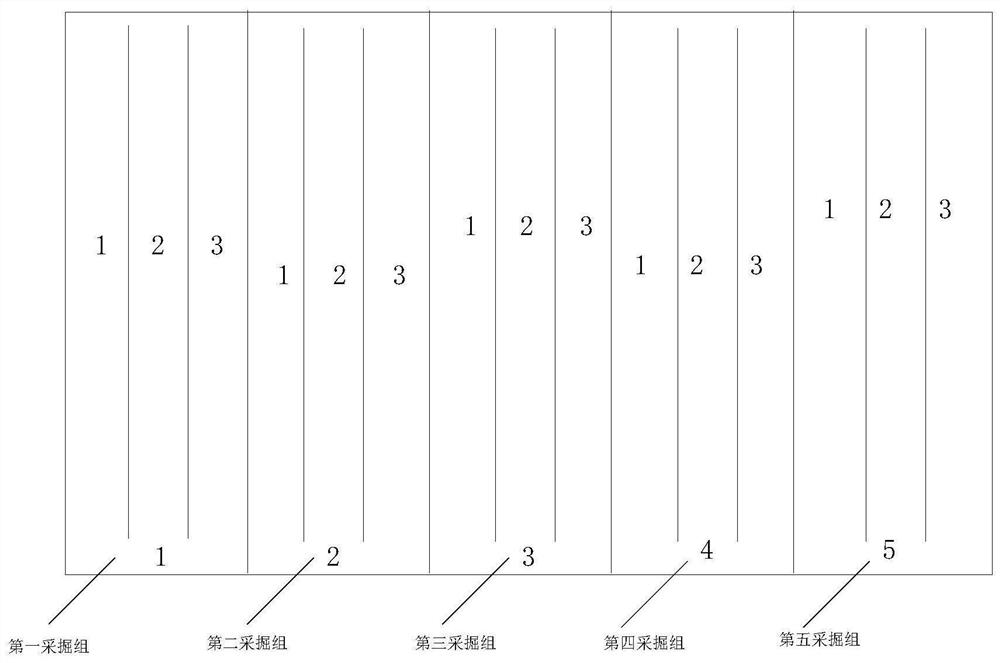

[0014] See figure 1 , figure 2 , the embodiment of the present invention provides a semi-continuous process combination step mining method without incision, including:

[0015] S110. Divide the mining area in the area to be mined, and the width of each mining area is equal and parallel to each other; S120. Number the mining areas, and mark three adjacent mining areas as 1, 2, and 3 , marked in sequence, that is, a plurality of mining groups are formed, and each of the mining groups includes the first panel, the second panel, and the third panel; Mining group, the third mining group...the Nth mining group; S140. Mining the first, second, and third panels of the first mining group to a first predetermined depth, and then mining the first panel to the first panel Two predetermined depths, mining the second width to the second predetermined depth, wherein the second predetermined depth is greater than the first predetermined depth; S150. Transfer the working face belt conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com