Underground pressure release valve and hydraulic shaping pipe column

A pressure relief valve and hydraulic technology, applied in the direction of wellbore/well valve device, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as troublesome operation, safety risk, low repair efficiency, etc., and achieve pressure relief speed Fast, improve the efficiency of pressure relief, improve the effect of shaping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

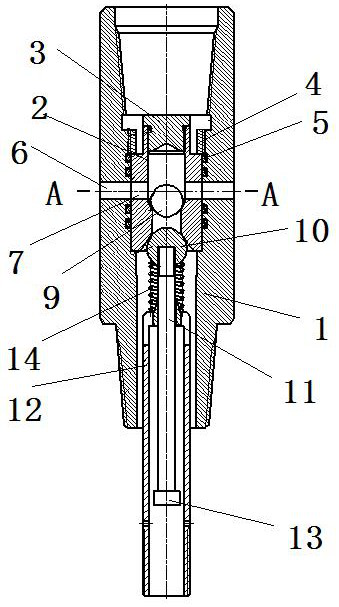

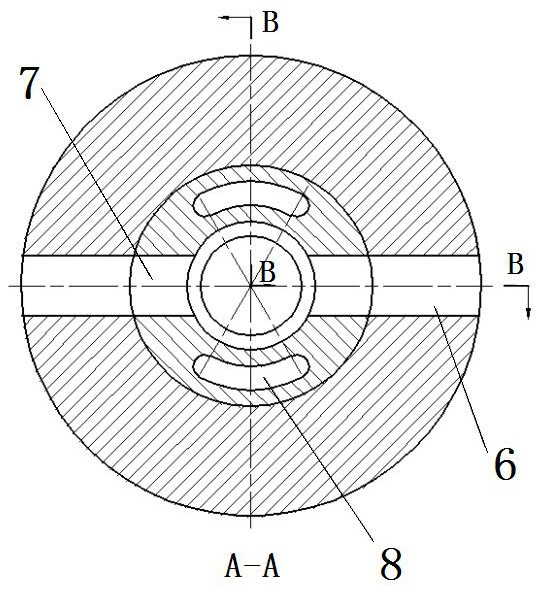

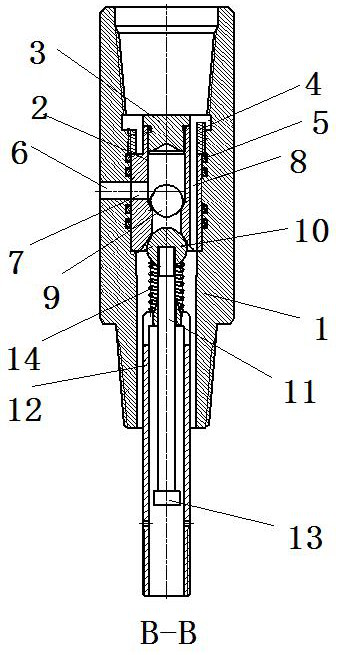

[0066] The downhole pressure relief valve of the present invention is installed in the hydraulic shaping pipe string when in use, and can automatically remove the pressure in the hydraulic shaping pipe string under certain trigger conditions. The installation position in the hydraulic shaping string and the connection relationship with other components in the hydraulic shaping string are introduced: the downhole pressure relief valve of the present invention is installed between the hydraulic anchor and the hydraulic booster when used, such as figure 1 As shown, the downhole pressure relief valve includes an outer sleeve 1, and the upper end of the outer sleeve 1 is provided with an internal thread section for connecting with the hydraulic anchor. The lower end of the outer casing 1 is provided with an external thread section for connecting with the cylinder body of the hydraulic booster, and the external thread section constitutes a lower connection section, and the inside of ...

specific Embodiment 2

[0077] The difference from Embodiment 1 is that the one-way conduction structure is a one-way valve installed at the liquid outlet, and the one-way valve includes two ring protrusions located at intervals inside the liquid outlet and protruding radially inward. In the direction in which the liquid in the valve seat flows out from the liquid outlet hole, the ring protrusion located upstream is the upstream ring protrusion, and the ring protrusion located downstream is the downstream ring protrusion. A spring and a small ball are installed between the two ring protrusions, and one end of the spring touches the top. On the downstream ring convex, the other end pushes the small ball against the middle hole of the upstream ring convex to block it. When the liquid in the outer casing flows out from the liquid outlet hole, it can flow out from the middle hole on the upstream ring protrusion and the downstream ring protrusion by overcoming the elastic force of the spring. The one-way ...

specific Embodiment 3

[0079]Different from Embodiment 1, the inner hole at the lower end of the valve seat is provided with a downward annular groove, and the valve core includes an upper valve column and a lower trigger rod, and the valve column is threadedly connected with the trigger rod. The outer peripheral surface of the spool is provided with a sealing ring for sealing cooperation with the side wall of the ring groove of the valve seat. The ring groove constitutes a valve port for matching with the valve core. between.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com