Heat-conducting fabric and preparation method thereof

A technology for fabrics and veils, applied in dyeing, fabric surface trimming, heating/cooling fabrics, etc., can solve problems such as low temperature resistance, inability to dye, and inability to use on a large scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides a kind of preparation method of heat-conducting fabric described in above-mentioned technical scheme, comprises the following steps:

[0042] The veil, ground yarn and connecting yarn are woven, dyed and shaped to obtain a thermally conductive fabric.

[0043] In the present invention, during the weaving process, the bottom yarn mainly appears on the inside of the fabric, that is, close to the skin surface, and forms a smooth texture, which can directly contact with the skin and absorb the heat of the skin instantly; the connecting yarn part appears on the surface, dissipating the heat After being exported, it is in direct contact with the air, which is good for heat dissipation. The veil appears on the top layer of the fabric, which absorbs the sweat from the bottom layer and evaporates on the surface to take away the heat.

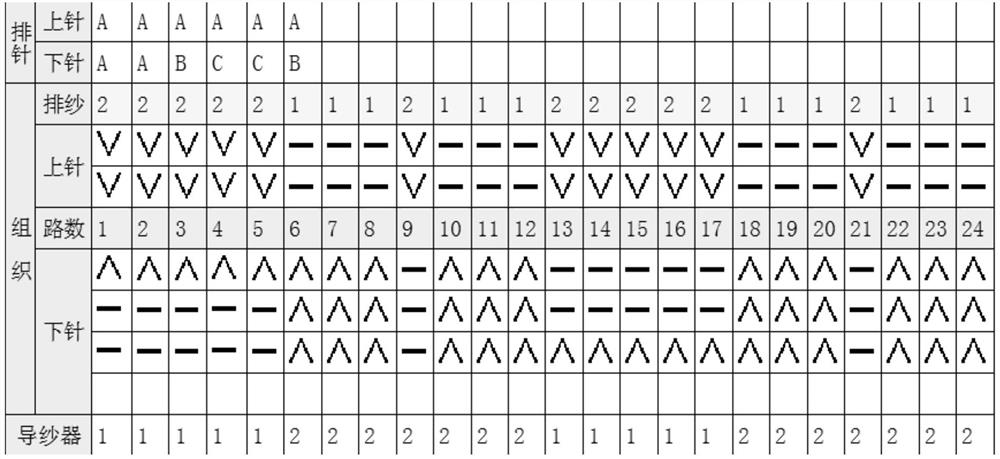

[0044] During the weaving process, the arrangement of upper needles is AAAAAA, and the arrangement of lower needl...

Embodiment 1

[0050] Embodiment 1 Polyester cover nylon bag polyester bird's eye cloth

[0051] The overall processing process is: material selection - veil twisting - weaving - dyeing - shaping - finished product - testing;

[0052] 1. Yarn selection, the surface layer is 150D144F polyester, the twist coefficient is 400, the bottom layer is 75D24F nylon-wrapped polyester yarn, in this core-spun yarn, the surface layer nylon accounts for 30%, and the inner layer polyester accounts for 70%;

[0053] 2. Use the weaving parameters shown in Table 1 to weave the fabric:

[0054] The weaving parameter that table 1 embodiment 1 adopts

[0055]

[0056] Among them, A, B, and C respectively represent three kinds of knitting needles with different butt heights, and the arrangement of A, B, and C represents the order of the knitting needles, which is called a row of needles; rows 1 and 2 represent two different yarns , that is, the No. 1 yarn is fed into the 1-5 road, and the No. 2 yarn is fed in...

Embodiment 2

[0065] Embodiment 2 Polyester cover nylon bag polyester plaid fabric

[0066] The overall processing process is: material selection - weaving - dyeing and finishing - shaping - finished product - testing;

[0067] 1. Yarn selection, the surface layer is 150D144F polyester, the bottom layer is 75D24F nylon-wrapped polyester yarn, of which nylon accounts for 40% and polyester accounts for 60%;

[0068] 2. The parameters of fabric weaving are shown in Table 4:

[0069] The weaving parameter that table 4 embodiment 2 adopts

[0070]

[0071] The weaving of embodiment 2 takes 10 paths as a cycle, No. 1 yarn (150D144F twisted polyester) is fed into No. 1, 2, 3, 4, and 5 paths, and No. 2 is fed into No. 6, 7, 8, 9, and 10 paths. Yarn (75D24F nylon covered polyester yarn). The upper needle row is AAAAAAA, and the lower needle row is AABCCB. The needles on the 1st and 5th roads are knitted into circles, and the lower needles are knitted into circles, floating lines, and floating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com