Thermally conductive polymer composite material with multi-level continuous network structure and preparation method

A network structure and composite material technology, applied in the field of thermally conductive polymer composite materials and preparation, can solve the problems of a single three-dimensional continuous thermally conductive network structure, heat transfer, large average distance, etc., and achieve simple and easily available raw materials, high thermal conductivity, average small distance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

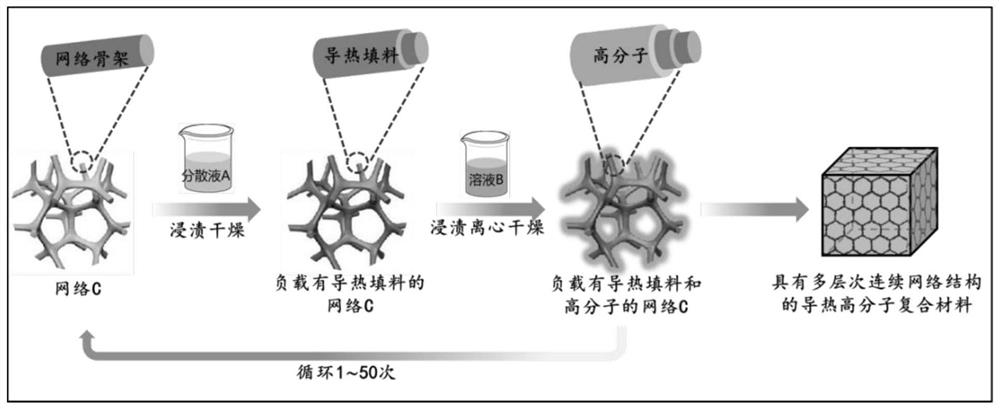

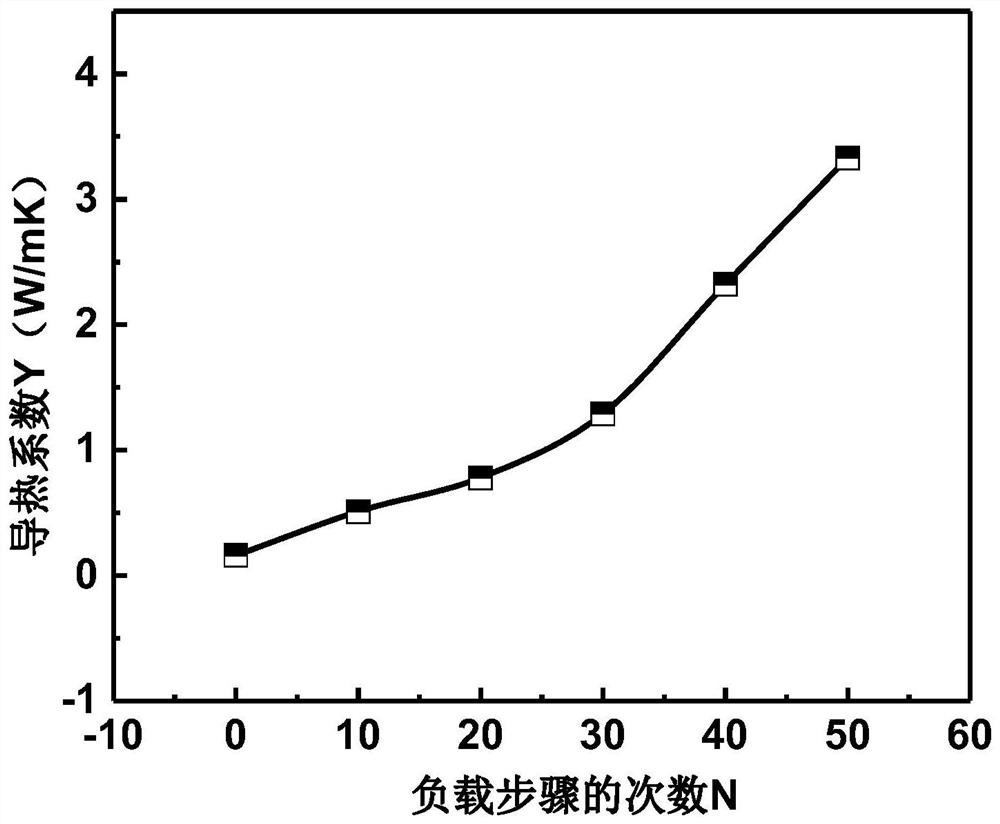

[0036] like figure 1 As shown, a preparation method of a thermally conductive polymer composite material with a multi-level continuous network structure comprises the following steps:

[0037]Prepare a network C, which is a polyurethane network with a pore size of 150 μm. Carry out the loading method for network C 50 times, each loading method is: immersing in dispersion A for 30 min, taking out and drying at 20°C for 0.5 h to obtain network C loaded with thermally conductive fillers, and immersing network C loaded with thermally conductive fillers solution B for 30min, taken out, centrifuged at 2000r / min for 30min, and dried at 20°C for 300min to obtain a thermally conductive polymer composite material, wherein,

[0038] The preparation method of dispersion liquid A is as follows: dispersing the thermally conductive filler in liquid D to obtain a mixture, ultrasonically treating the mixture with a cell crusher for 60 min to obtain dispersion liquid A, the power of ultrasonic...

Embodiment 2

[0056] A preparation method of a thermally conductive polymer composite material with a multi-level continuous network structure, comprising the following steps:

[0057] Prepare a network C, which is a melamine network with a pore size of 100 μm. Carry out the loading method for network C 50 times, each loading method is: immersing in dispersion A for 1 min, taking out and drying at 50 ° C for 1 h to obtain a network C loaded with thermally conductive fillers, and immersing network C loaded with thermally conductive fillers in the solution B for 20min, take out, centrifuge at 1000r / min for 15min, and dry at 50°C for 200min to obtain a thermally conductive polymer composite material, wherein,

[0058] The preparation method of dispersion A is as follows: dispersing the thermally conductive filler in liquid D to obtain a mixture, ultrasonically treating the mixture with a cell crusher for 5 min to obtain dispersion A, the power of ultrasonic treatment is 800W, and the concentra...

Embodiment 3

[0062] A preparation method of a thermally conductive polymer composite material with a multi-level continuous network structure, comprising the following steps:

[0063] Prepare a network C, which is a cellulose network with a pore size of 50 μm. Carry out the loading method for network C 50 times, each loading method is: immersing in dispersion A for 10 min, taking out and drying at 50°C for 3 h to obtain network C loaded with thermally conductive fillers, and immersing network C loaded with thermally conductive fillers into the solution B for 1 min, take out, centrifuge at 500 r / min for 15 min, and dry at 50 °C for 30 min to obtain a thermally conductive polymer composite material, wherein,

[0064] The preparation method of dispersion liquid A is as follows: dispersing the thermally conductive filler in liquid D to obtain a mixture, and ultrasonically treating the mixture with a cell crusher for 30 min to obtain dispersion liquid A, the power of ultrasonic treatment is 500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com