An efficient and environmentally friendly polishing anion resin production system and production process

A production process and anion resin technology, applied in the field of polishing anion resin production system and production process, can solve the problems of large amount of waste water containing salt, acid and alkali, large amount of ultrapure water, long production cycle, etc. The effect of economic benefits, pollution reduction, production cost reduction and environmental protection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

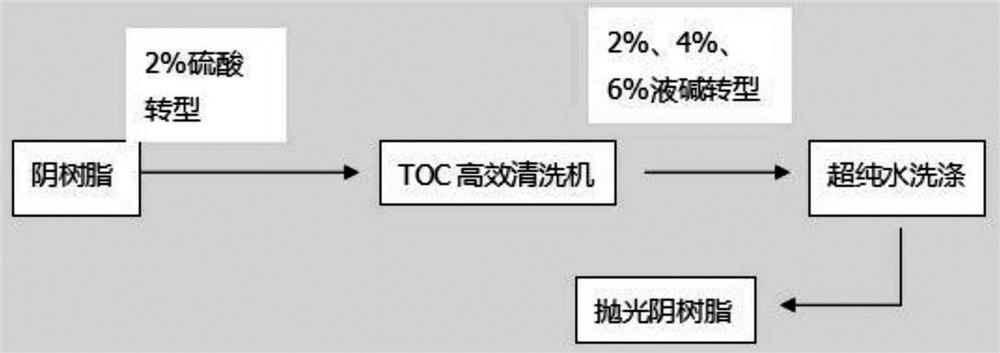

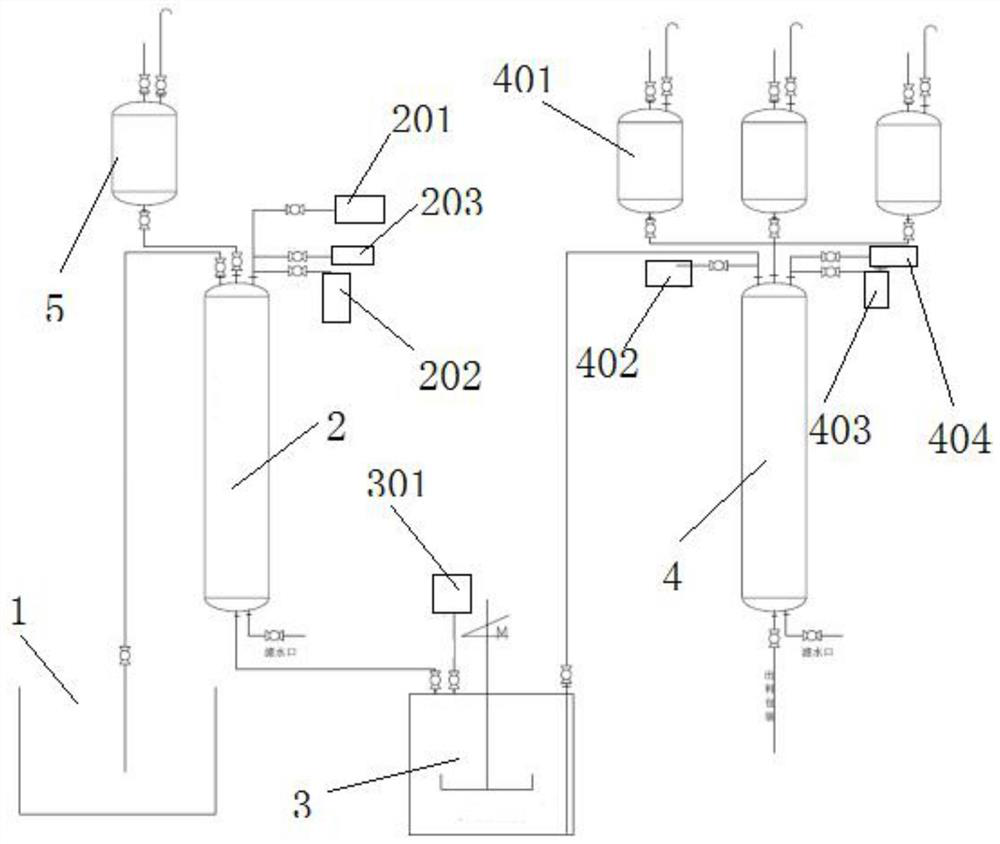

[0039] In the sulfuric acid head tank 5, add the sulfuric acid that the volume is 4D and the mass fraction is 2%, and add the Cl that the volume is 2D in the feed bin 1 - Type 201×7 strong basic anion, and Cl - Type 201 × 7 strong basic anions are vacuum pumped into the sulfuric acid type transition column 2, the sulfuric acid in the sulfuric acid header tank 5 is dripped into the sulfuric acid transition column 2, and the Cl - Type 201×7 strongly basic anion exchange resin converts SO into 4 2-type to obtain intermediate A; open the nitrogen valve of sulfuric acid type transformation column 2 to pressurize and filter the liquid in intermediate A, and close the water filter valve, pressurized intermediate A into TOC high-efficiency cleaning machine 3 and add 15 megohm ultrapure water with a volume of 4D to the TOC high-efficiency cleaning machine 3 for cleaning; after the TOC high-efficiency cleaning machine 3 has finished cleaning, open the water filter valve, drain the cle...

Embodiment 2

[0041] In the sulfuric acid head tank 5, add the sulfuric acid that the volume is 4D and the mass fraction is 3%, and add the Cl that the volume is 2D in the feed bin 1 - Type 201×7 strong basic anion, and Cl - Type 201 × 7 strong basic anions are vacuum pumped into the sulfuric acid type transition column 2, the sulfuric acid in the sulfuric acid header tank 5 is dripped into the sulfuric acid transition column 2, and the Cl - Type 201×7 strongly basic anion exchange resin converts SO into 4 2- type to obtain intermediate A; open the nitrogen valve of sulfuric acid type transformation column 2 to pressurize and filter the liquid in intermediate A, and close the water filter valve, pressurized intermediate A into TOC high-efficiency cleaning machine 3 and add 15 megohm ultrapure water with a volume of 4D to the TOC high-efficiency cleaning machine 3 for cleaning; after the TOC high-efficiency cleaning machine 3 has finished cleaning, open the water filter valve, drain the cl...

Embodiment 3

[0043] In the sulfuric acid head tank 5, add the sulfuric acid that the volume is 4D and the mass fraction is 24%, and add the Cl that the volume is 2D in the feed bin 1 - Type 201×7 strong basic anion, and Cl - Type 201 × 7 strong basic anions are vacuum pumped into the sulfuric acid type transition column 2, the sulfuric acid in the sulfuric acid header tank 5 is dripped into the sulfuric acid transition column 2, and the Cl - Type 201×7 strongly basic anion exchange resin converts SO into 4 2- type to obtain intermediate A; open the nitrogen valve of sulfuric acid type transformation column 2 to pressurize and filter the liquid in intermediate A, and close the water filter valve, pressurized intermediate A into TOC high-efficiency cleaning machine 3 and add 15 megohm ultrapure water with a volume of 4D to the TOC high-efficiency cleaning machine 3 for cleaning; after the TOC high-efficiency cleaning machine 3 has finished cleaning, open the water filter valve, drain the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com