Rivet punching machine with complete servo driving system and working method thereof

A technology of servo drive and working method, applied in the field of stamping riveting machines, can solve the problems of high price and large equipment, and achieve the effects of improving efficiency, improving riveting quality and facilitating maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the features and advantages of this patent more obvious and easy to understand, the following special examples are described in detail as follows:

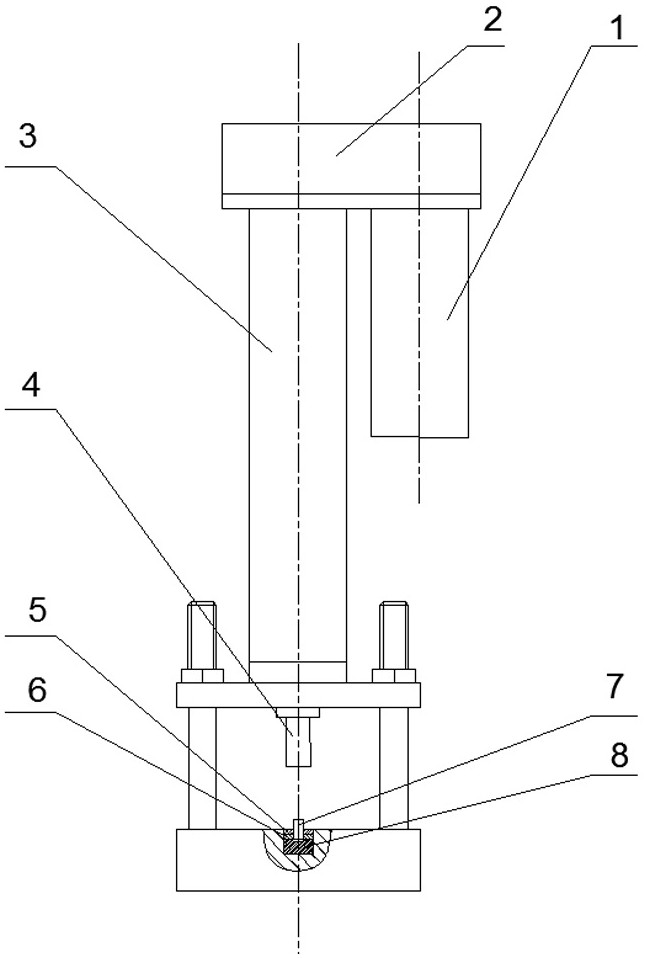

[0025] like figure 1 , image 3 As shown, the present embodiment provides a design scheme of a stamping riveting machine with a complete servo drive system, which mainly includes: a servo motor 1, a screw mechanism 2, a cylinder body 3, a pressure platform, a pressure sensor 8 and a controller.

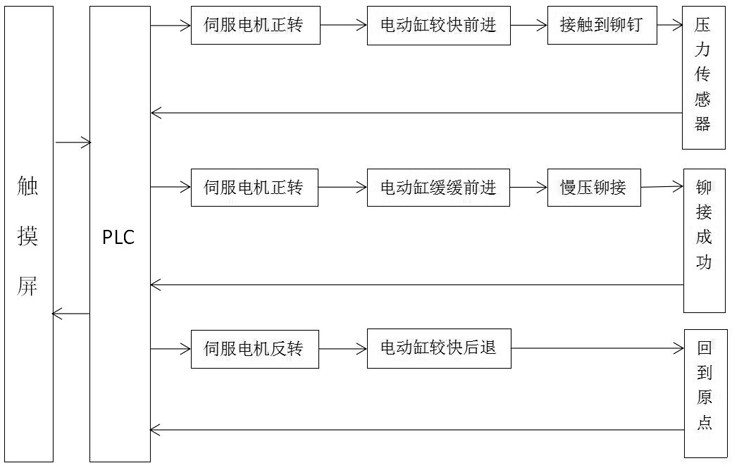

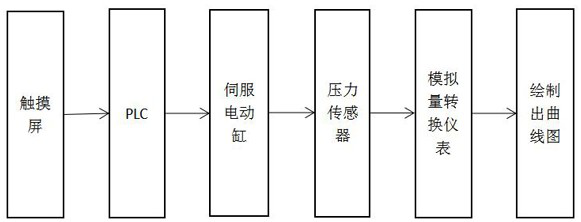

[0026] Among them, the screw mechanism 2 converts the rotation of the output shaft of the servo motor 1 into the linear motion of the punch 4 in the cylinder 3; the pressure receiving platform is located on the linear motion path of the punch 4; the pressure sensor 8 is installed at the bottom of the pressure receiving platform ; The servo motor 1 and the pressure sensor 8 are respectively electrically connected to the controller, and the pressure sensor 8 is used as a trigger switch for the working state of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com