P-type folded edge bending process

A technology, bending forming technology, applied in the field of stamping dies, can solve the problem that the negative angle cannot be guaranteed not to spring back, and achieve the effect of simplifying the structure and eliminating elastic stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

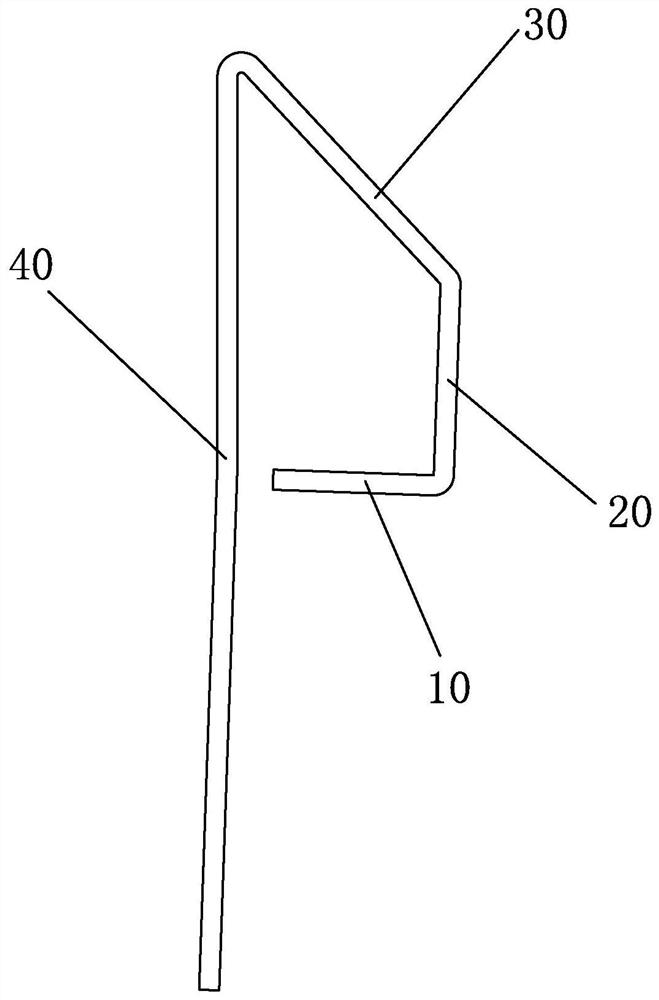

[0024] figure 1 The bending process used for the P-shaped hem shown in , includes the following:

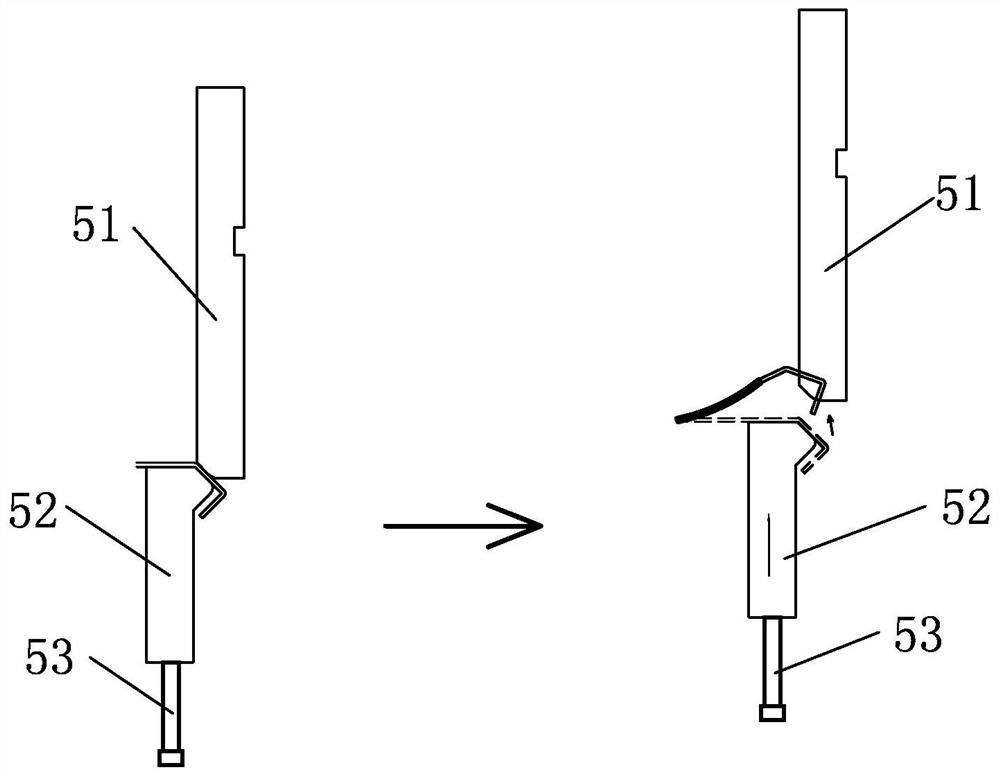

[0025] The first step is to bend the folded edge down to shape;

[0026] The second step is to bend the folded edge 2 downward;

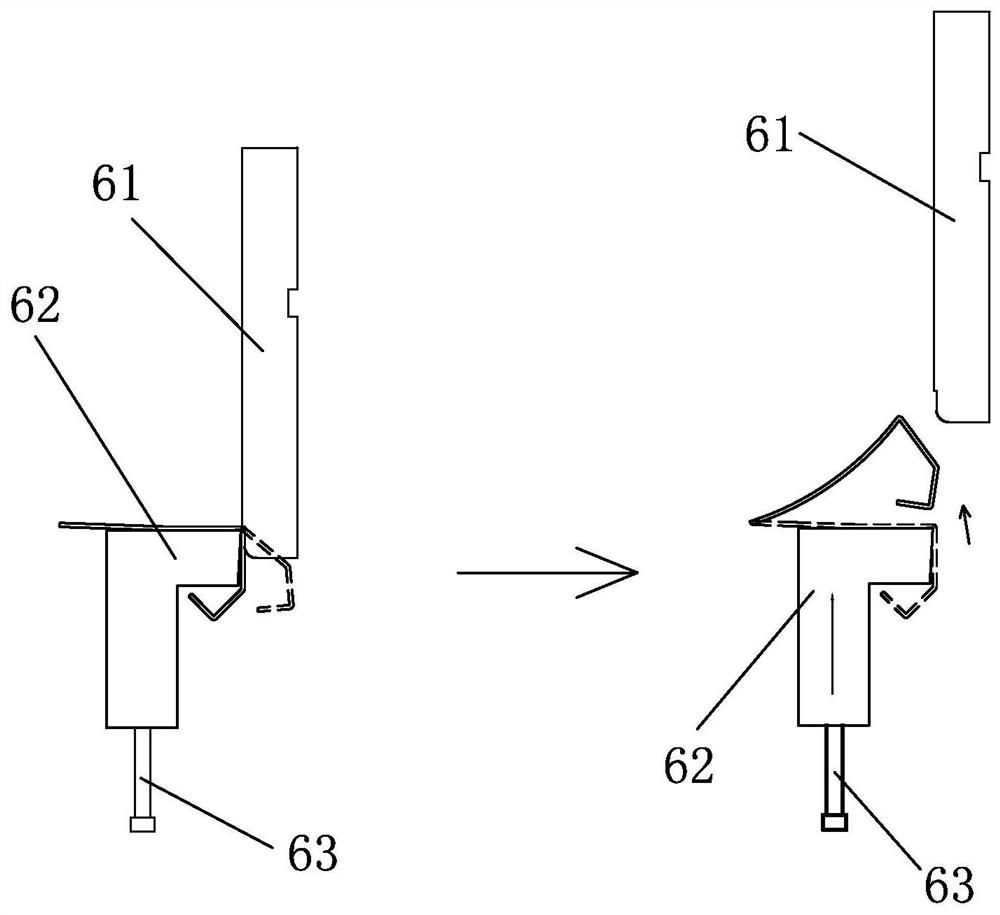

[0027] The third step is to bend the folded edge three downwards, and the angle between the folded edge three and the bottom edge is 140°;

[0028] The fourth step is to continue to bend the folded edge three downwards, and the angle between the folded edge three and the bottom edge is 90°;

[0029] The fifth step is to continue to bend the folded edge three downwards, and the angle between the folded edge three and the bottom edge is 43°.

[0030] Adding a step before the existing two-step forming method, the material at the three-fold bending line of the hem is stretched continuously three times intermittently, completely eliminating the elastic stress of the material, and ensuring that the negative angle of the P-type hem is no longer formed afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com