Multifunctional starch size mixing equipment

A multi-functional technology for starch slurrying, applied in mixers, food science, food forming, etc., can solve the problems of starch slurry concentration reduction, achieve the effects of improving uniformity, accelerating production speed, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

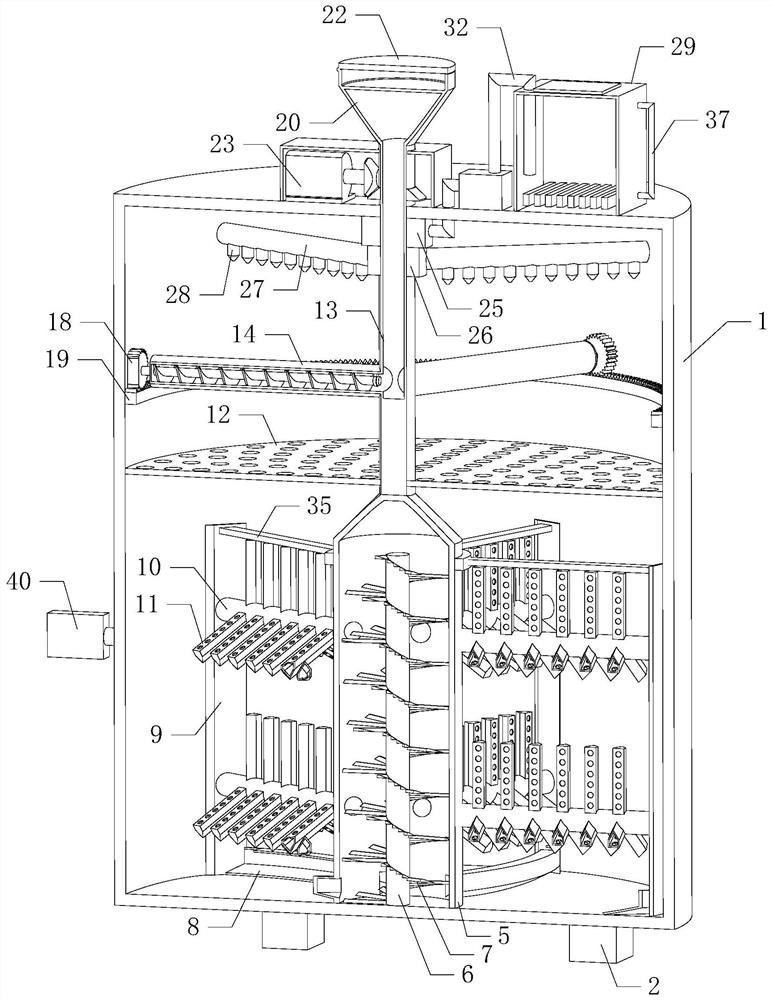

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

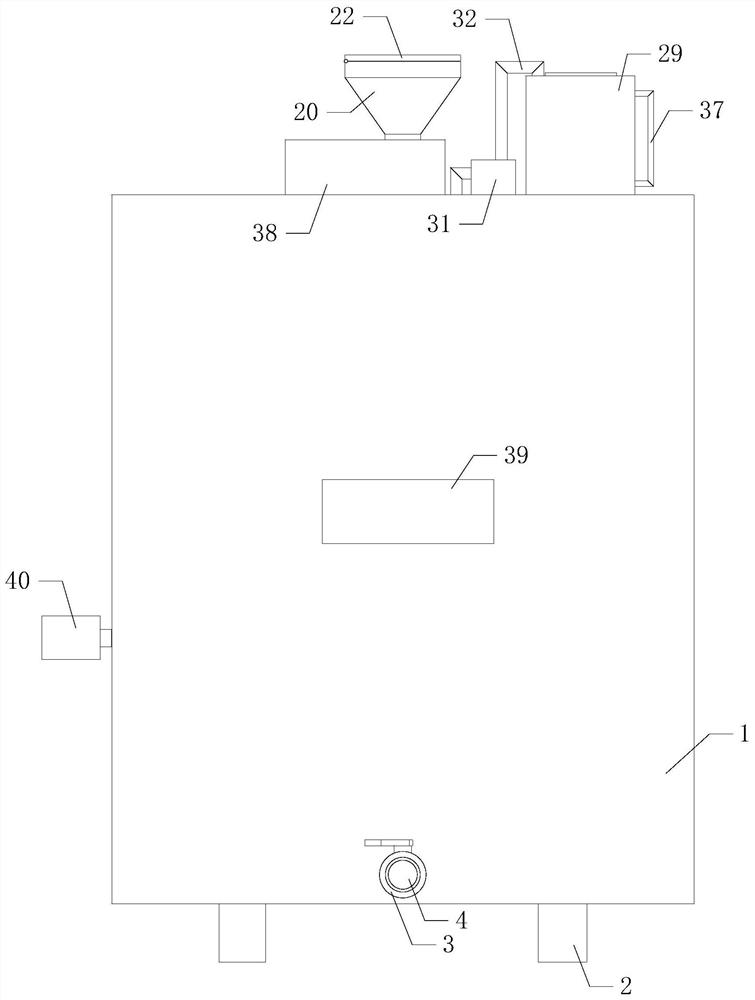

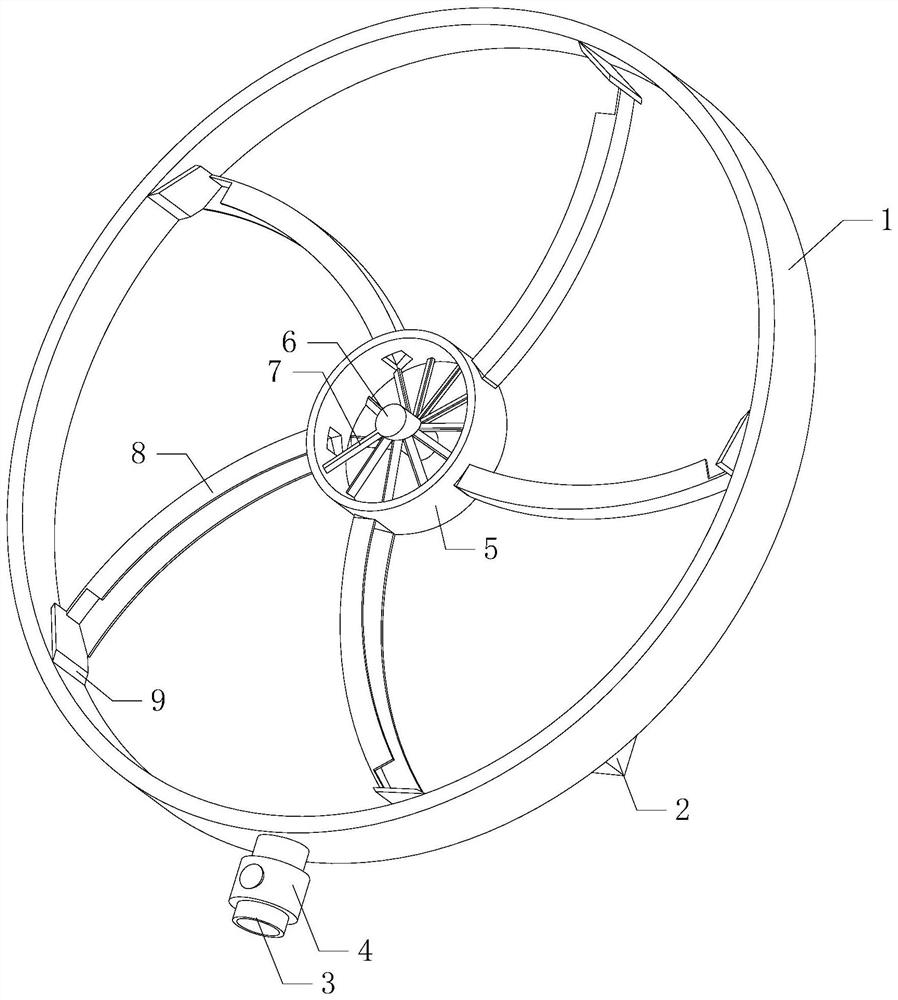

[0022] Such as Figure 1 to Figure 7 As shown, a kind of multifunctional starch mixing equipment of the present invention, when it is working, open the first cover plate 22, the external starch can be poured in the feed hopper 20 through the top of the feed hopper 20, and the starch in the feed hopper 20 The starch passes through the filter plate 21 and falls into the hollow shaft 13. The filter plate 21 can filter the starch to prevent larger particles in the starch from entering the equipment and causing blockage to the equipment. Turn on the motor 23, and the motor 23 passes through two sets of bevel gears. 24 drives the hollow shaft 13 to rotate slowly, and the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com