Food combined processing workshop matched with culturing farm and production process

A processing workshop and combined processing technology, which is applied in the direction of processed meat, poultry processing, food freezing, etc., can solve the problems of low degree of centralized utilization of resources, prolonging the working cycle, increasing transportation costs, etc., to reduce the impact on quality and improve work Efficiency, reduce the effect of quality decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

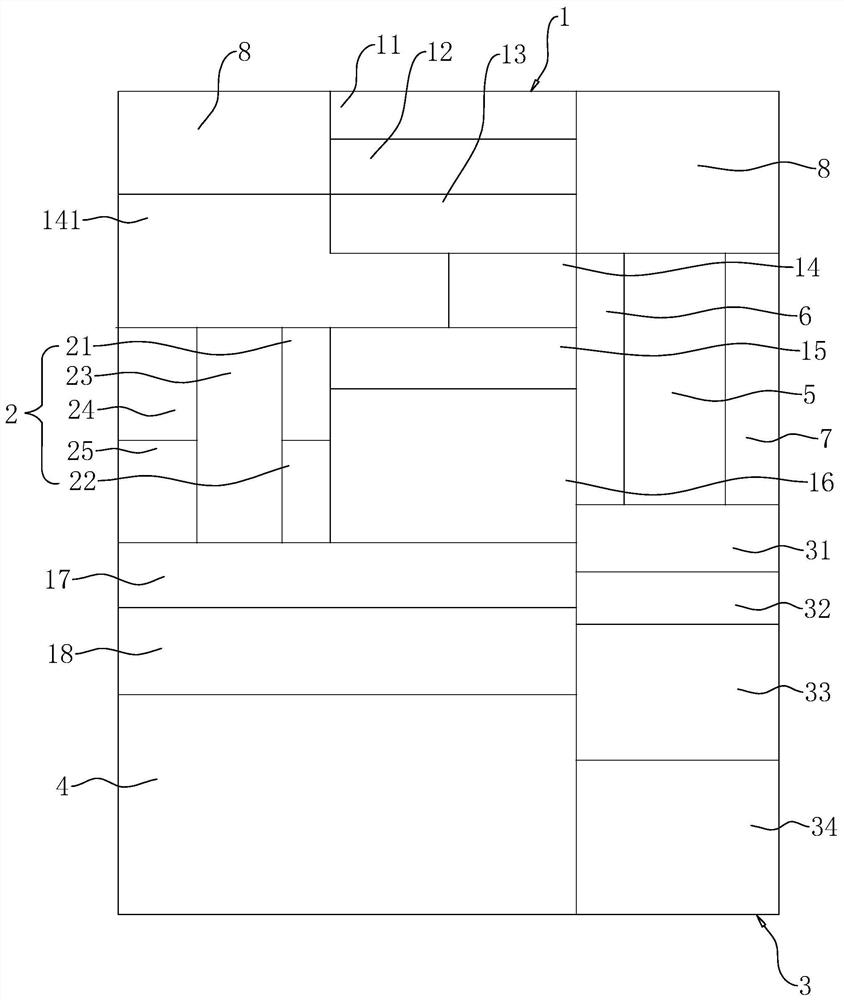

[0050] The following is attached Figure 1-6 The application is described in further detail.

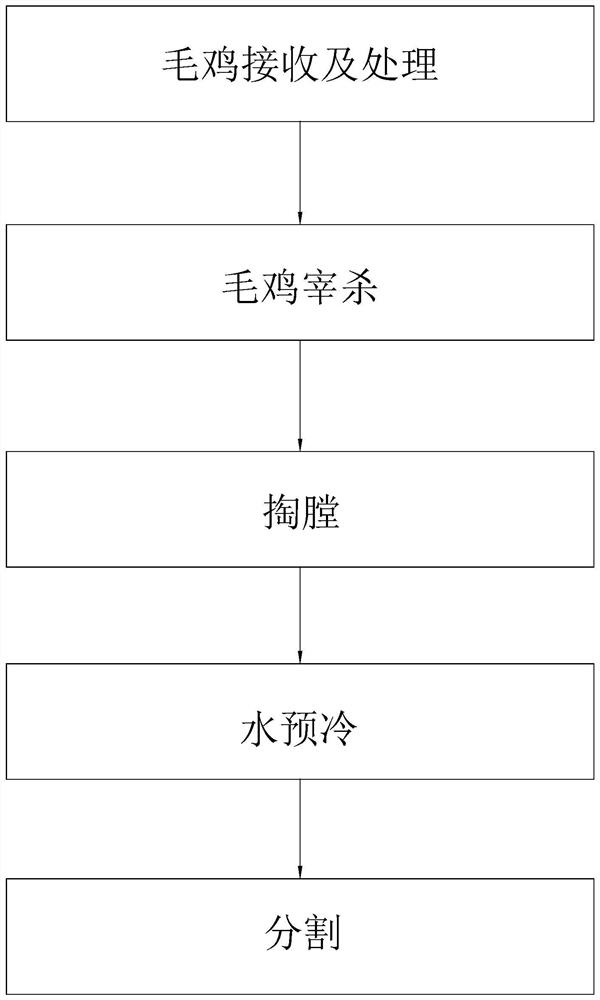

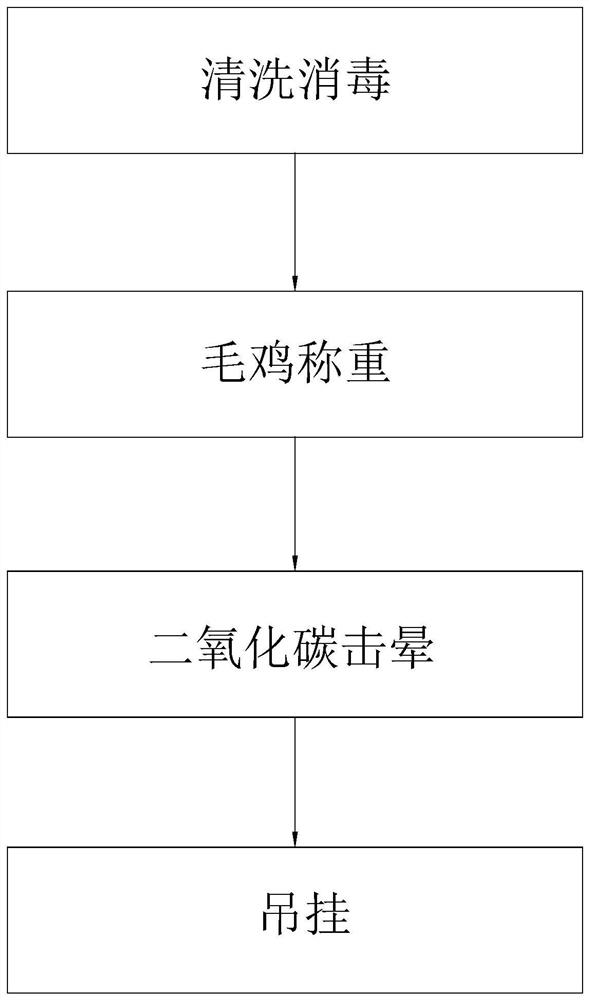

[0051] The embodiment of the present application discloses a combined food processing workshop that cooperates with the farm, which is used to process the poultry raised in the farm and produce various foods. figure 1 , the combined processing workshop is equipped with a chicken slaughtering and processing workshop 1, a conditioning product processing workshop 2, a cooked food processing workshop 3 and a fully automatic warehouse 4; through each processing workshop, chickens are gradually processed to achieve a highly centralized utilization of resources. Multiple production lines cooperate with the processing of chickens, which can reduce the cost of intermediate transportation. When processing chickens in different forms, it is more convenient to transfer raw materials in each processing workshop.

[0052] The chicken slaughtering and processing workshop 1 is divided into a non-cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com