Stator core, stator, permanent magnet synchronous motor, compressor and refrigeration equipment

A permanent magnet synchronous motor and stator core technology, applied in the field of compressors, can solve problems such as vibration and noise, and achieve the effects of improving vibration and noise, reducing the difficulty of production technology, and reducing radial electromagnetic force waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

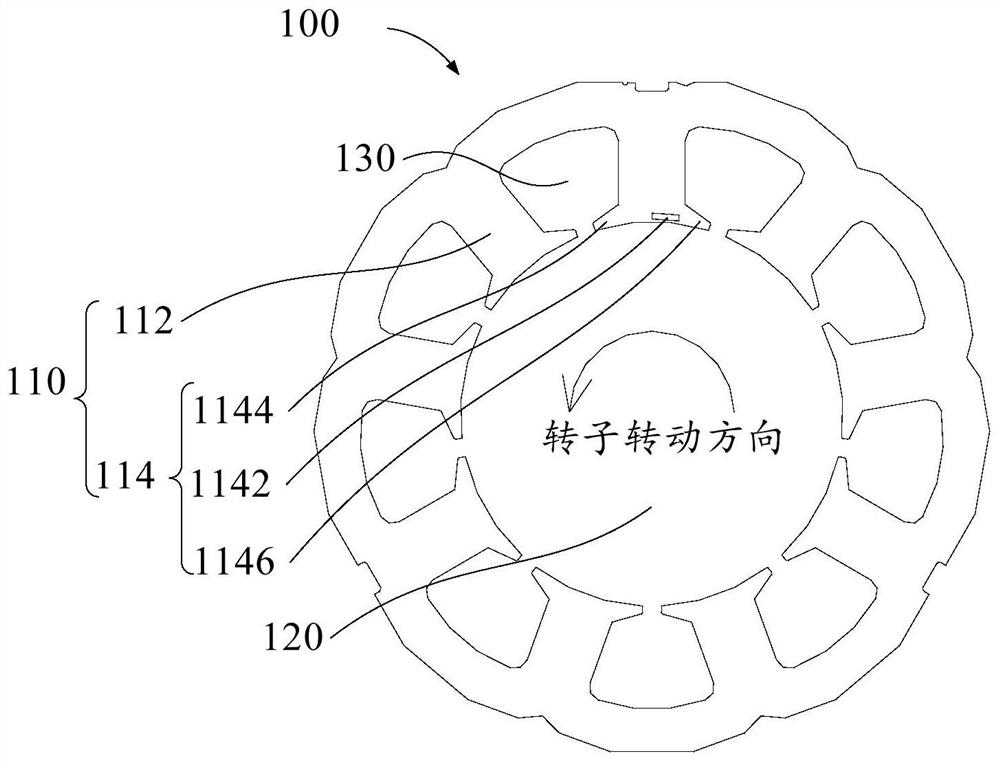

[0075] figure 1 It shows one of the structural schematic diagrams of the stator core according to the embodiment of the present invention, figure 2 Shows the second structural schematic diagram of the stator core according to the embodiment of the present invention, wherein, as figure 1 and figure 2 As shown, the stator core consists of:

[0076] The stator inner hole 120 is used to pass through the rotor; a plurality of stator punches, each stator punch has a thickness, and the plurality of stator punches are stacked along the axial direction of the stator inner hole 120, and the stator punches include a stator yoke and a A plurality of stator teeth 110 distributed in the circumferential direction of the yoke; wherein, a magnetic conduction hole 1142 is opened along the thickness direction of the stator punch.

[0077] In the embodiment of the present invention, the stator core is provided with a stator inner hole 120 , and the rotor of the motor can pass through the sta...

Embodiment 2

[0082] In some embodiments of the present invention, such as figure 2As shown, the stator tooth 110 includes: a tooth root 112 connected with the stator yoke; a tooth crown 114 connected with the end of the tooth root 112 away from the stator yoke; The thickness of at least one tooth crown 114 on at least one stator punching plate is provided with a magnetic conduction hole 1142, along the axial direction of the tooth root, the projection of the magnetic conduction hole 1142 on the tooth crown makes the tooth crown 114 away from the tooth root 112 is divided into a first tooth crown surface 1144 and a second tooth crown surface 1146 , the area of the first tooth crown surface 1144 is smaller than the area of the second tooth crown surface 1146 .

[0083] In the embodiment of the present invention, along the axial direction of the tooth root, the projection of the magnetic conduction hole 1142 on the tooth crown 114 separates the surface of the tooth crown 114 away from th...

Embodiment 3

[0088] In some embodiments of the present invention, the number of stator punching pieces is multiple, and the plurality of stator punching pieces include: at least one first stator punching piece 100; at least one second stator punching piece, the first stator punching piece 100 and the second stator punch are stacked along the axial direction of the stator inner hole 120 , and the second stator punch is provided with a magnetic conduction hole 1142 .

[0089] In the embodiment of the present invention, the stator core of the motor includes a plurality of stacked stator punches, wherein the plurality of stator punches include at least one first stator punch 100 and at least one second stator punch. The first stator punching piece 100 and the second stator punching piece are stacked along the axial direction of the stator inner hole 120 .

[0090] Specifically, the first stator punching sheet 100-the second stator punching sheet-the first stator punching sheet 100 can be stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com