Gear vibration signal source underdetermined blind source separation method based on density and compressed sensing

An underdetermined blind source separation and compressive sensing technology, applied in the field of underdetermined blind source separation of gear vibration signal sources, can solve the problems of source signal number estimation error, source signal separation error, poor noise robustness, etc., and achieve high efficiency. High, few parameters, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

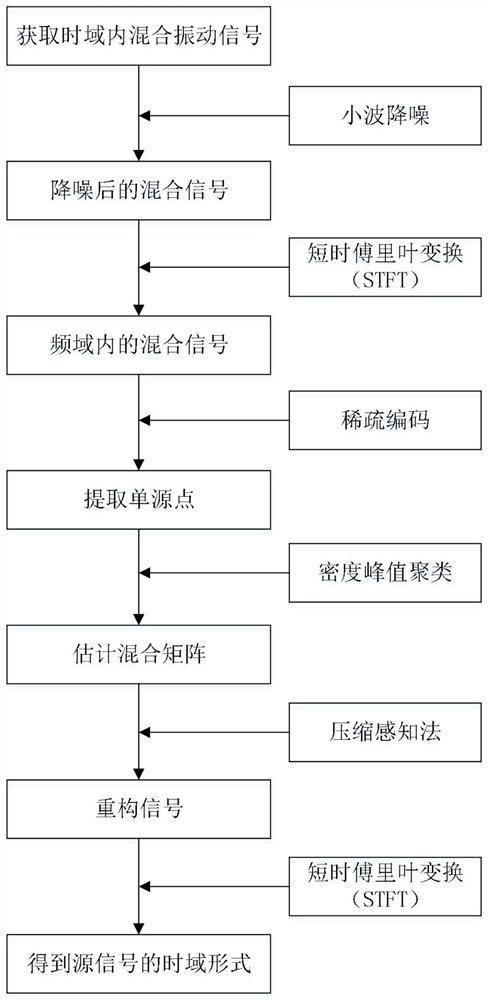

[0051]Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

[0052] Such as figure 1 As shown, the present invention provides a method for underdetermined blind source separation of gear vibration sources based on density and compressive sensing, which specifically includes the following steps:

[0053] Step 1: Use the method of wavelet noise reduction to perform noise reduction preprocessing on the collected signal.

[0054] If the function φ(t) satisfies the condition:

[0055]

[0056] Then φ(t) is called the generating function of a wavelet or the basic wavelet, where, is the Fourier transform of φ(t), the wavelet function is obtained by stretching and translating the basic wavelet function, expressed as:

[0057]

[0058] In the formula, a and b represent the stretching parameter and translation parameter of wavelet transform respectively.

[0059] For any signal f(t), its wavelet transform pair is:

[0060]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com