Automatic grading loading and unloading device in floor static load test

A static load test and automatic grading technology, applied in the direction of measuring devices, analytical materials, instruments, etc., can solve the problems of complex floor ultimate bearing capacity test, and achieve the effect of reducing labor and time costs, good guiding significance, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be pointed out that the embodiment is only a specific elaboration of the present invention, and should not be regarded as limiting the present invention. The purpose of the embodiment is to make those skilled in the art better To better understand and reproduce the technical solution of the present invention, the protection scope of the present invention should still be defined by the claims.

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

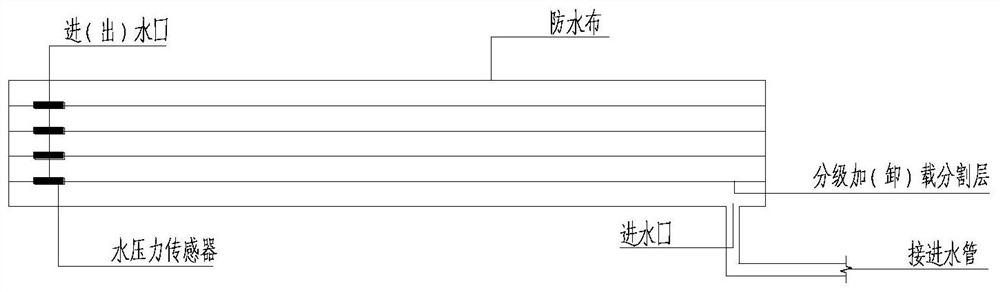

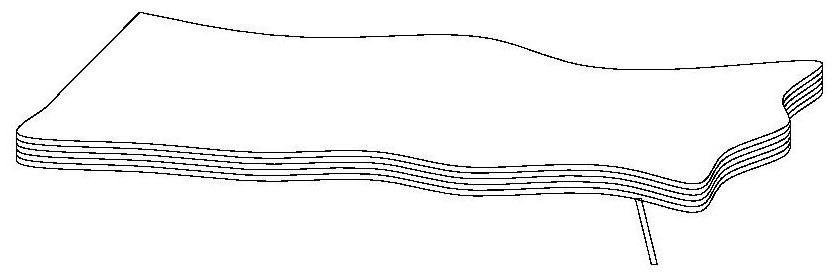

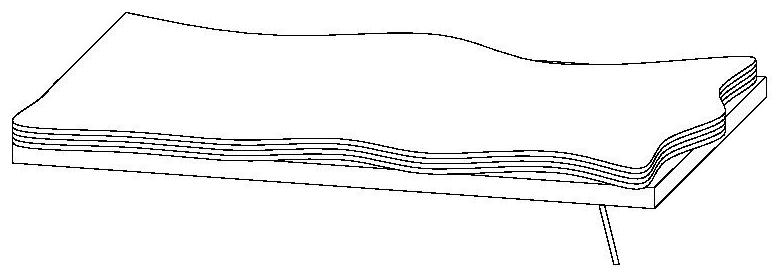

[0024] Such as figure 1 , an automatic graded loading and unloading device in a floor static load test, including a load-bearing device made of PVC waterproof cloth, the load-bearing device is provided with an inlet and outlet, an in-out valve, a connecting channel, and a sensor for sensing load parameters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com