Automatic spraying type reel cleaning device and using method thereof

A spray type and reel technology, which is applied in the field of automatic spray type reel cleaning device, can solve the problem of not ensuring whether the cleaning effect of the reel reaches a consistent standard, affecting the overall yield of flexible printed circuit boards, manpower and The problem of high time cost and other problems can reduce product defects, reduce labor and time costs, and improve cleaning ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

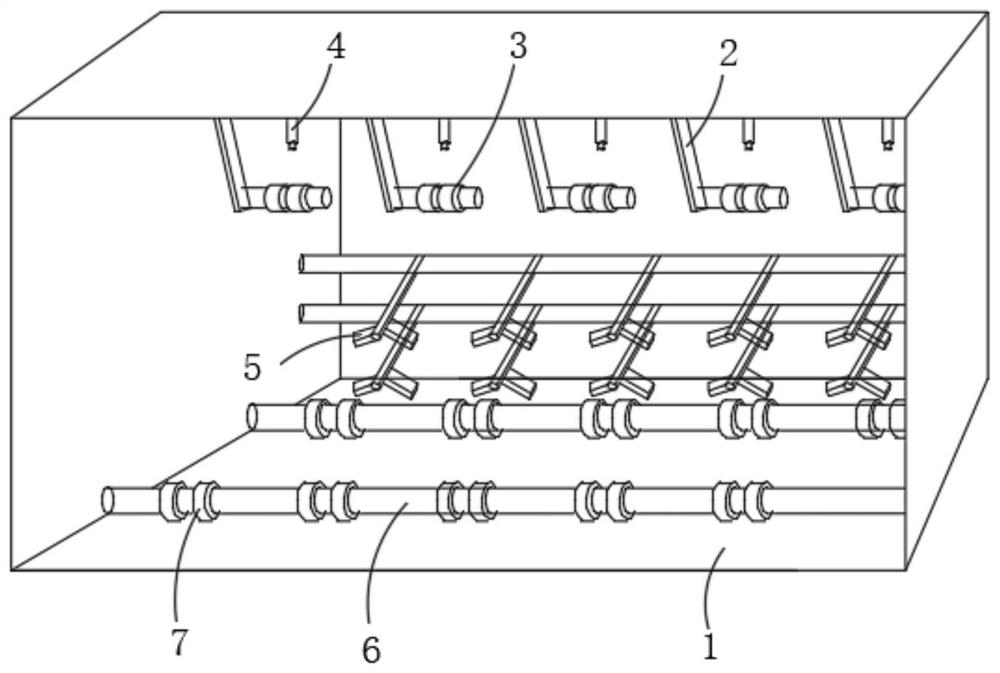

[0023] Such as figure 1 As shown, the embodiment of the present invention provides an automatic spray type reel cleaning device, including a box body 1, a plurality of adjustment shafts 2 are movably installed on the inner top of the box body 1, and the adjustment shafts 2 can be connected by rotation or can be It is a sliding connection. When the size of the reel changes, the upper clamp 3 can be moved by the adjustment shaft 2 to adjust to a suitable diameter of the outer disc of the reel. A plurality of first nozzles 4 are fixedly installed on the top, and the plurality of first nozzles 4 are respectively located in the middle of two adjacent adjustment shafts 2, and a plurality of sets of second nozzles 5 are fixedly installed in the middle position inside the box body 1. Two driving shafts 6 are installed in rotation at the inner bottom, and a plurality of lower clamps 7 are fixedly installed on the outer surfaces of the two driving shafts 6. The front of the box body 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com