A drying device for alumina production and processing

A drying device, alumina technology, applied in the direction of drying gas arrangement, drying solid materials without heating, drying solid materials, etc., can solve the problems of rapid dehydration of alumina powder, and achieve the effect of increasing drying and dehydration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

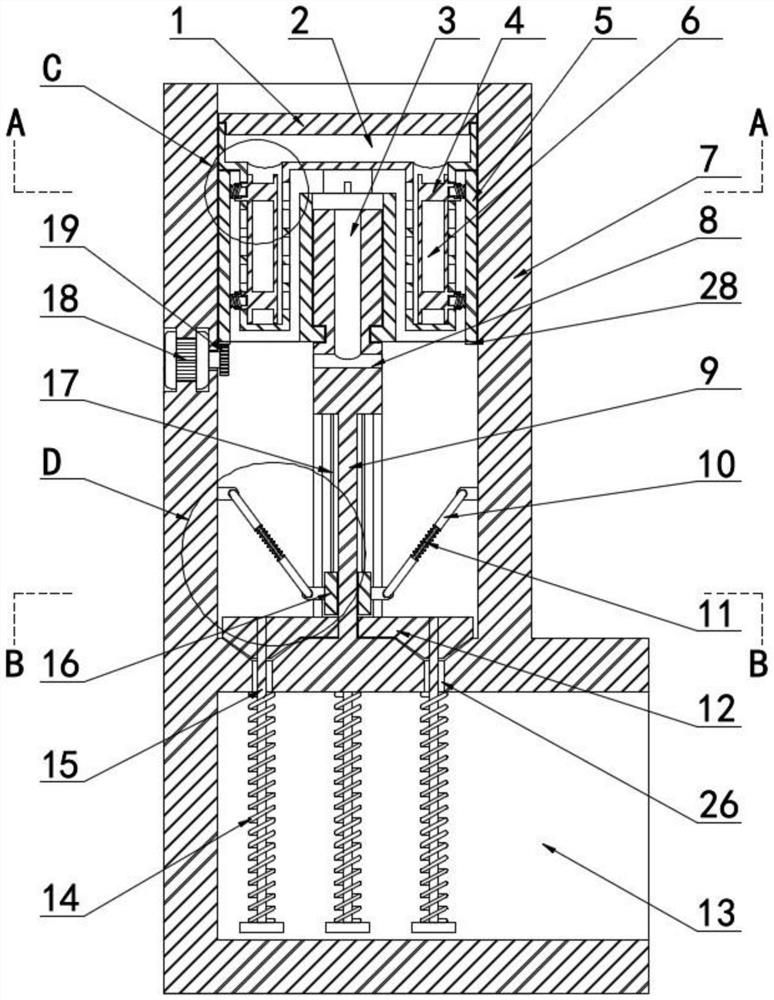

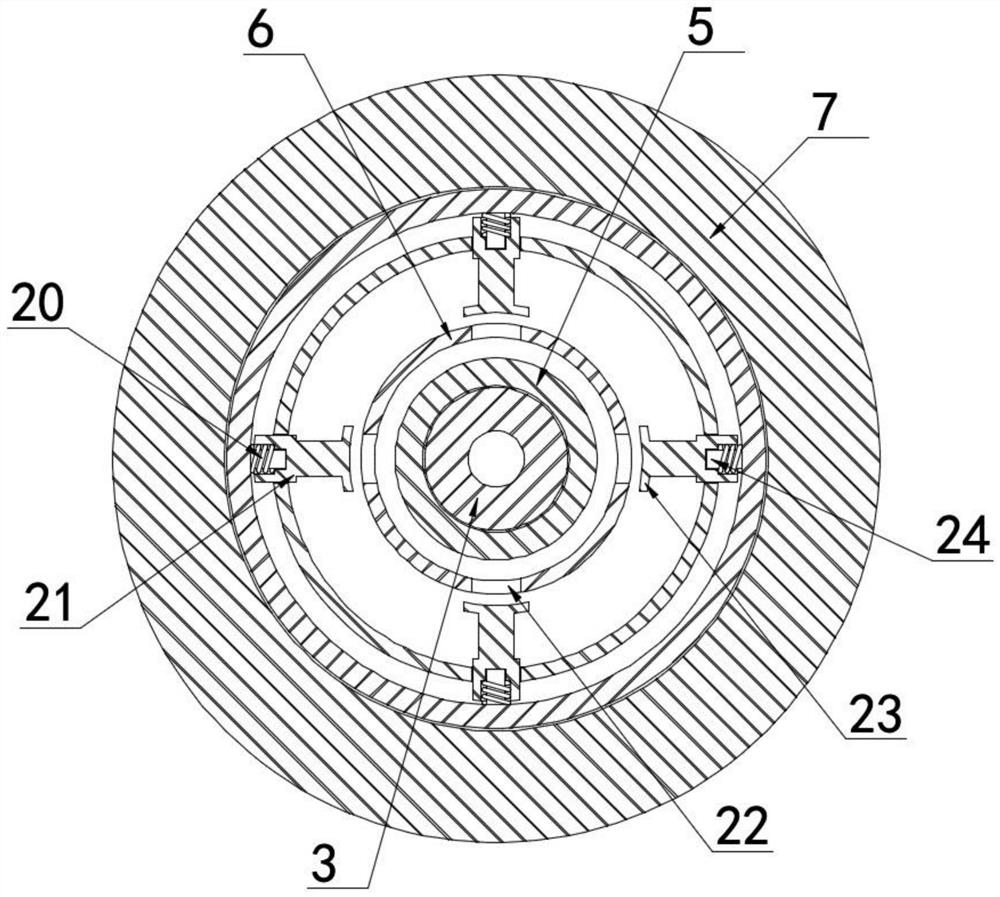

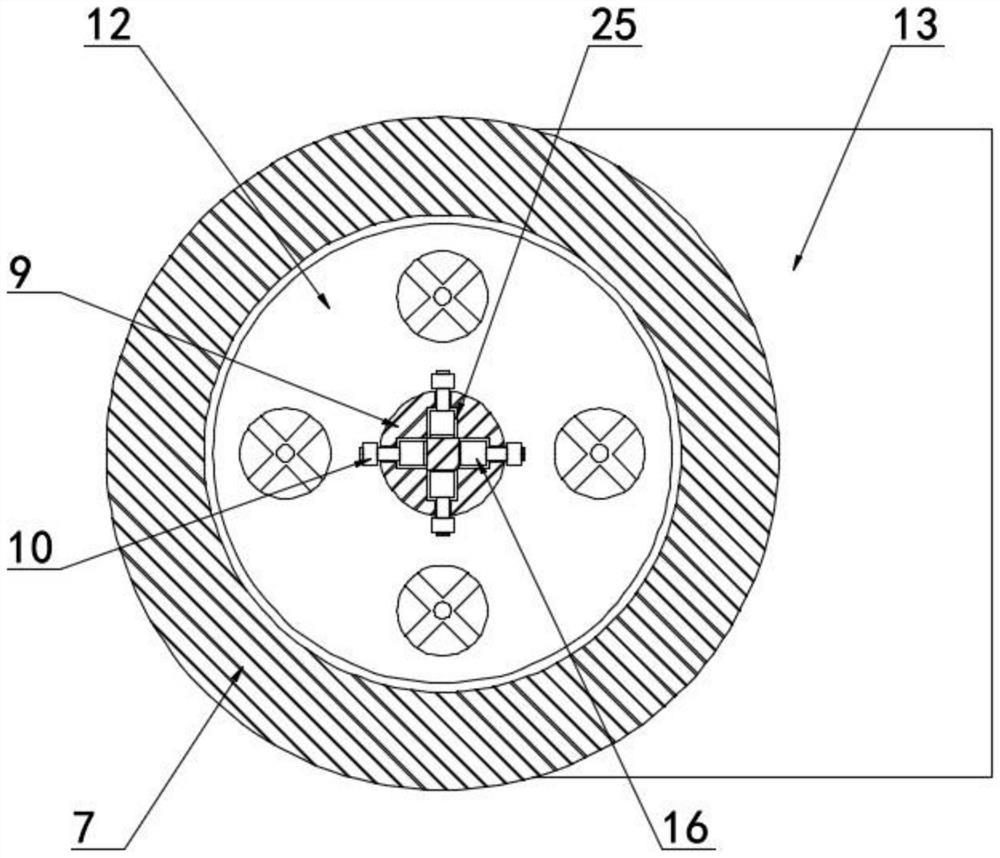

[0034] Embodiment one, with reference to Figure 1-5 , a drying device for alumina production and processing, including a vertical cylindrical shell 7 and a horizontal cylindrical shell 13 fixedly connected to the bottom of the vertical cylindrical shell 7, the center of the vertical cylindrical shell 7 A central fixed installation column 9 is provided, and the outer side of the central fixed installation column 9 is provided with a centrifugal separation and dehydration rotary sleeve 5, and the centrifugal separation and dehydration rotary sleeve 5 is abutted with the upper opening receiving cavity plate 2, and the top opening of the upper opening receiving cavity plate 2 The opening is screwed and connected with a protective and airtight upper screw cover 1, and the bottom end of the upper opening accommodation chamber groove plate 2 is fixedly connected with a two-way opening vertical drum 6, and the side of the two-way opening vertical drum 6 is close to the central fixed ins...

Embodiment 2

[0035] Embodiment two, refer to Figure 1-5 , the connection between the vertical cylindrical shell 7 and the horizontal cylindrical shell 13 is fixedly connected with the bottom end of the central fixed installation column 9, and the outer side of the central fixed installation column 9 is provided with a sleeve plate 12, and the bottom end of the sleeve plate 12 is connected to the horizontal The top of the side wall of the cylindrical shell 13 abuts, the bottom end of the centrifugal separation and dehydration rotating sleeve 5 is fixedly connected with an annular meshing rack 28, and the output end of the drive pair 18 is fixedly connected with an meshing gear plate 19, and the meshing gear plate 19 and the annular meshing rack 28 meshing connection, the horizontal inner communication groove 8 communicates with the vertical inner communication groove 3, the top of the vertical inner communication groove 3 communicates with the inner cavity of the centrifugal separation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com