Suspension Bridge Horizontal Anchorage Structure and Construction Method

A construction method and horizontal technology, applied in the direction of suspension bridge, bridge construction, bridge form, etc., can solve the problems of traffic lanes, large occupied space of platform, increase of excavation and concrete volume, large anchor-tunnel interaction, etc., to achieve The effect of shortening the construction period, reducing the amount of excavation, and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

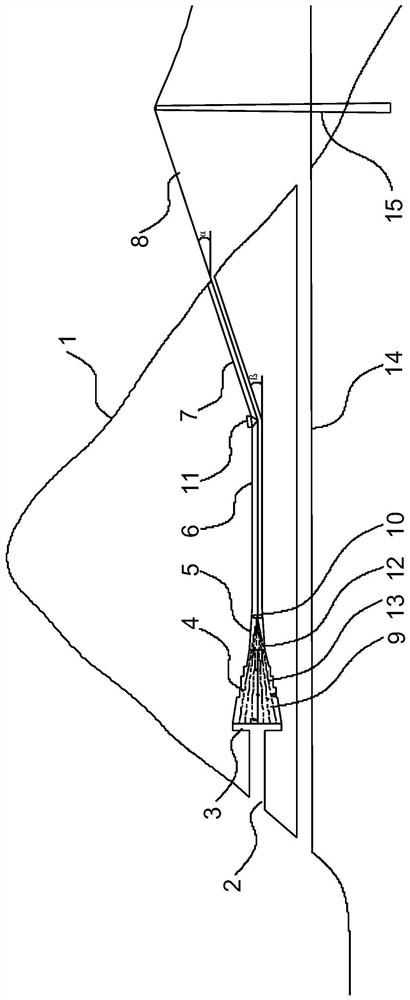

[0043] The main cable tunnel in the first embodiment is composed of a horizontal construction main cable flat tunnel and an obliquely upward construction main cable inclined tunnel, specifically as figure 1 As shown, the swivel saddle 11 is installed in the turning section between the main cable flat hole 6 and the main cable inclined hole 7, and the main tower 15 higher than the main cable flat hole 6 openings is provided on the side of the suspension bridge, and the main cable 8 of the suspension bridge Pulled from the main tower 15 into the main cable inclined hole 7, horizontally enter the main cable flat hole 6 and the front anchor chamber 5 through the swivel saddle 11; The swivel saddle 11 arranged in the turning section of the main cable flat hole 6 and the main cable inclined hole 7 is inverted, and the inverted swivel saddle foundation is as follows Figure 5 As shown, in order to expand the form of the foundation, the upper part is arc-shaped, and the lower part is ...

Embodiment 2

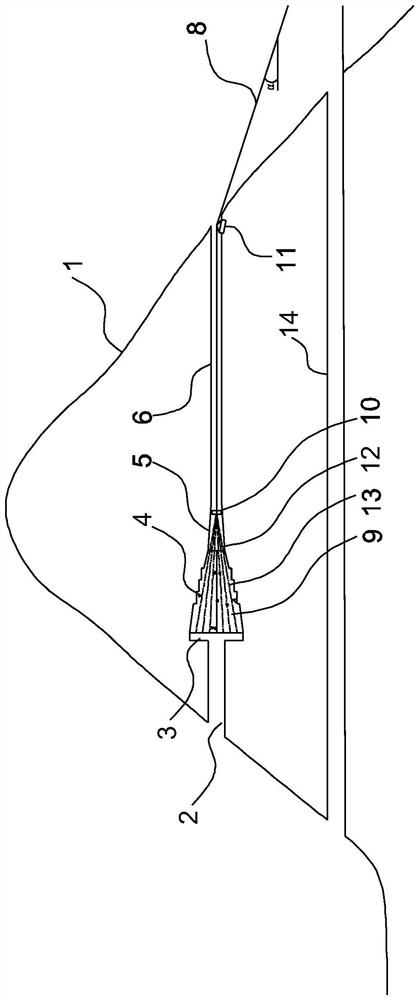

[0044] The main cable tunnel in the embodiment two is set to horizontal construction main cable flat tunnel, specifically as figure 2 As shown, only the main cable flat hole 6 is provided with a cable saddle 11 near the opening of the suspension bridge without a tower side, and the cable saddle 11 is inclined to the side of the suspension bridge, and the main cable 8 of the suspension bridge is introduced into the main cable flat hole 6 obliquely from below. Hole, and horizontally enter the main cable flat hole 6 and the front anchor chamber 5 after turning the cable saddle 11. In this state, the inclination angle α of the main cable must be as small as possible, so that the foundation pressure of the slanted upward and inverted swivel saddle is as low as possible.

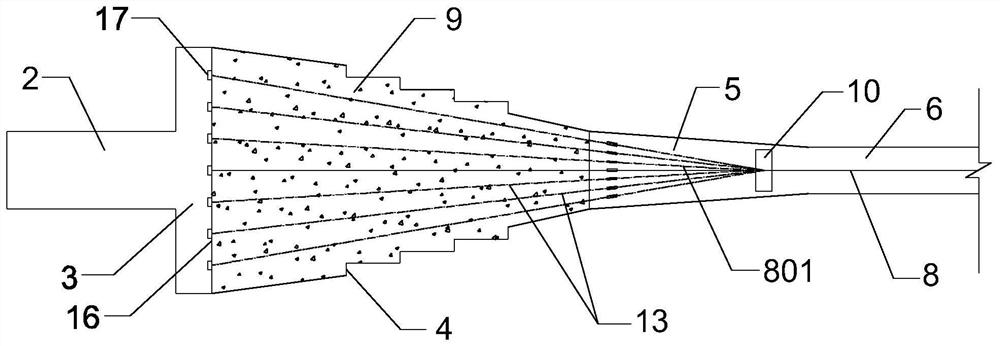

[0045] A kind of suspension bridge horizontal type anchorage structure provided in the embodiment, such as Figure 1 to Figure 3 As shown, a loose cable saddle 10 is installed in the front anchor chamber 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com