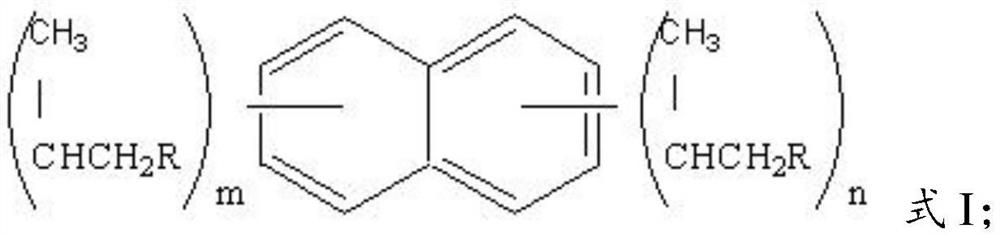

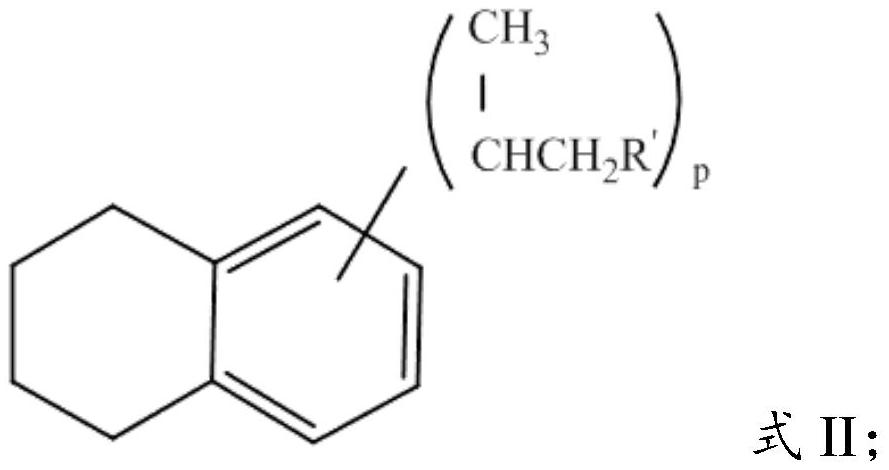

Alkyl naphthalene high-temperature heat conduction oil base oil and preparation method and application thereof

A technology of alkylnaphthalene and heat transfer oil, which is applied in chemical instruments and methods, base materials, petroleum industry, etc., and can solve the problem of high temperature of base oil of alkyl naphthalene high temperature heat transfer oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0047]The present invention also provides a method of preparing an alkyl naphthalene high temperature heat-conducting oil based on the above technical solution, including the following steps:

[0048]Four hydroxaphthalene, naphthalene and the first catalyst were mixed to give a mixture;

[0049]The olefin was added to the mixture, and the reaction was reacted after the second catalyst was added to obtain the alkylhthalene high temperature heat-conducting oil base oil; the olefin was 1-decene or 1-tertiethylene.

[0050]The present invention mixes tetrahydronaphthalene, naphthalene, and a first catalyst to obtain a mixture. The present invention is not particularly limited to the specific manner of the mixing, and can be well known to those skilled in the art.

[0051]After the mixture was obtained, the olefin droplets were added to the mixture, and the reaction was reacted after the second catalyst was added to obtain the alkylhthalene high temperature heat-conducting oil base oil; the olefin w...

Example Embodiment

[0064]Example 1

[0065]0.1 mol naphthalene, 0.2 mol tetrahydronaphthalene and 0.04 mol of trichloride were added to the stirred tank, and 0.5 mol1-decene was added dropwise, and the remaining 0.08 mol of trichloride was added twice; heated to 50 ° C reaction 5 hours; cooled, 1 wt% sodium hydroxide solution; water washed into neutral; dry sulfate dried overnight, filtered; 380 ° C evaporate low fraction; decolor, to obtain alkylkaronap, 20, 20, respectively, 20 %, 65%, and 15% of alklene, alkyl tetrahydronaphthalene and mixtures of polyethylene olefins (PAO). The primer is 380 ° C; pour point -43 ° C; 0 ° C viscosity 225 cSt, -20 ° C viscosity 2680 cSt; viscosity index 95.

[0066]The alkyl naphthalene thermos produced in Example 1 performs an infrared spectrum chart, and the results arefigure 1Indicated.

[0067]97 g of the alkyl-carnaphthalene carname-carnotenap admixture was added to 110 ° C, stirred to 110 ° C, stirred for 1 h; 1 g of an antioxidant 2,6-di-tert-butyl pair THC (T501), sti...

Example Embodiment

[0068]Example 2

[0069]0.1 mol naphthalene, 0.3 mol tetrahydronaphthalene and 0.06 mol of trichloride were added to the stirred tank, and 0.9 mol 1-tertiene was added dropwise, and the remaining 0.12 mol of trichloride was added twice; heated to 55 ° C The reaction was 5.6 hours; 1 wt% sodium hydroxide solution was added; water was washed into neutral; no water sulfate was dried overnight, filtered; 2. 0. 0. The low fraction was evaporated. The mass content is 23%, 59% and 18% alklene, alkyl tetrahydronaphthalene, and a mixture of poly alpha olefins (PAO). The primary distillation site is 380 ° C; pour point -41 ° C; 0 ° C viscosity 230 cSt, -20 ° C viscosity 2776 CST; viscosity index 100.

[0070]The alkyl nap thereof produced in Example 2 performs an infrared spectrum chart, and the results arefigure 1Indicated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com