Heavy-load solid tire tread rubber material

A solid tire and tread rubber technology, which is applied to special tires, tire parts, transportation and packaging, etc., can solve problems such as tire cracking, wear, and peeling, and achieve increased durability, increased practicality, and increased use time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

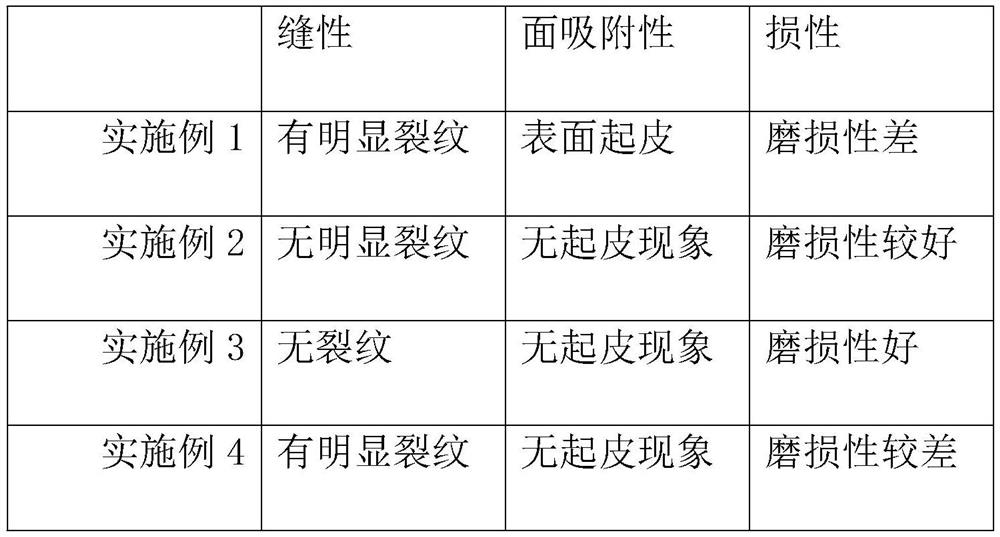

Embodiment 1

[0031] Embodiment 1, a kind of heavy-duty solid tire tread compound provided by the present invention comprises rubber and compounding agent, and described rubber comprises natural rubber, styrene-butadiene rubber and butadiene rubber, and described compounding agent comprises carbon black, sulfur, vulcanization Accelerators, anti-aging agents, anti-cracking agents and softeners;

[0032] Described rubber (by weight) is respectively: 40 parts of natural rubber, 40 parts of styrene-butadiene rubber, 40 parts of butadiene rubber;

[0033] The compounding agent (by weight) is respectively: 40 parts of carbon black, 2 parts of sulfur, 10 parts of vulcanization accelerator, 5 parts of anti-aging agent, 5 parts of anti-cracking agent, 3 parts of softening agent;

[0034] Also includes a processing method, specifically the following preparation steps:

[0035] S1: Put quantitative natural rubber, styrene-butadiene rubber and butadiene rubber into the cutting machine to cut off;

[...

Embodiment 2

[0056] Embodiment 2, a kind of heavy-duty solid tire tread compound provided by the present invention comprises rubber and compounding agent, and described rubber comprises natural rubber, styrene-butadiene rubber and butadiene rubber, and described compounding agent comprises carbon black, sulfur, vulcanization Accelerators, anti-aging agents, anti-cracking agents and softeners;

[0057] Described rubber (by weight) is respectively: 45 parts of natural rubbers, 45 parts of styrene-butadiene rubbers, 45 parts of butadiene rubbers;

[0058] The compounding agent (by weight) is respectively: 45 parts of carbon black, 2.5 parts of sulfur, 14 parts of vulcanization accelerator, 6 parts of anti-aging agent, 6 parts of anti-cracking agent, 5 parts of softening agent;

[0059] Also includes a processing method, specifically the following preparation steps:

[0060] S1: Put quantitative natural rubber, styrene-butadiene rubber and butadiene rubber into the cutting machine to cut off;...

Embodiment 3

[0081] Embodiment 3, a kind of heavy-duty solid tire tread compound provided by the present invention comprises rubber and compounding agent, and described rubber comprises natural rubber, styrene-butadiene rubber and butadiene rubber, and described compounding agent comprises carbon black, sulfur, vulcanized Accelerators, anti-aging agents, anti-cracking agents and softeners;

[0082] Described rubber (by weight) is respectively: 50 parts of natural rubber, 50 parts of styrene-butadiene rubber, 50 parts of butadiene rubber;

[0083] The compounding agent (by weight) is respectively: 50 parts of carbon black, 3 parts of sulfur, 18 parts of vulcanization accelerator, 8 parts of anti-aging agent, 8 parts of anti-cracking agent, 7 parts of softening agent;

[0084] Also includes a processing method, specifically the following preparation steps:

[0085] S1: Put quantitative natural rubber, styrene-butadiene rubber and butadiene rubber into the cutting machine to cut off;

[008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com