Forking and lifting dual-purpose loading and unloading machine

A loading and unloading machine and dual-purpose technology, which is applied in the directions of loading/unloading, transportation and packaging, etc., can solve the problems that the life safety of operators cannot be fully guaranteed, the danger of manual loading and unloading, and the cost of loading and unloading increase, so as to achieve flexible and changeable use , easy to move, save floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

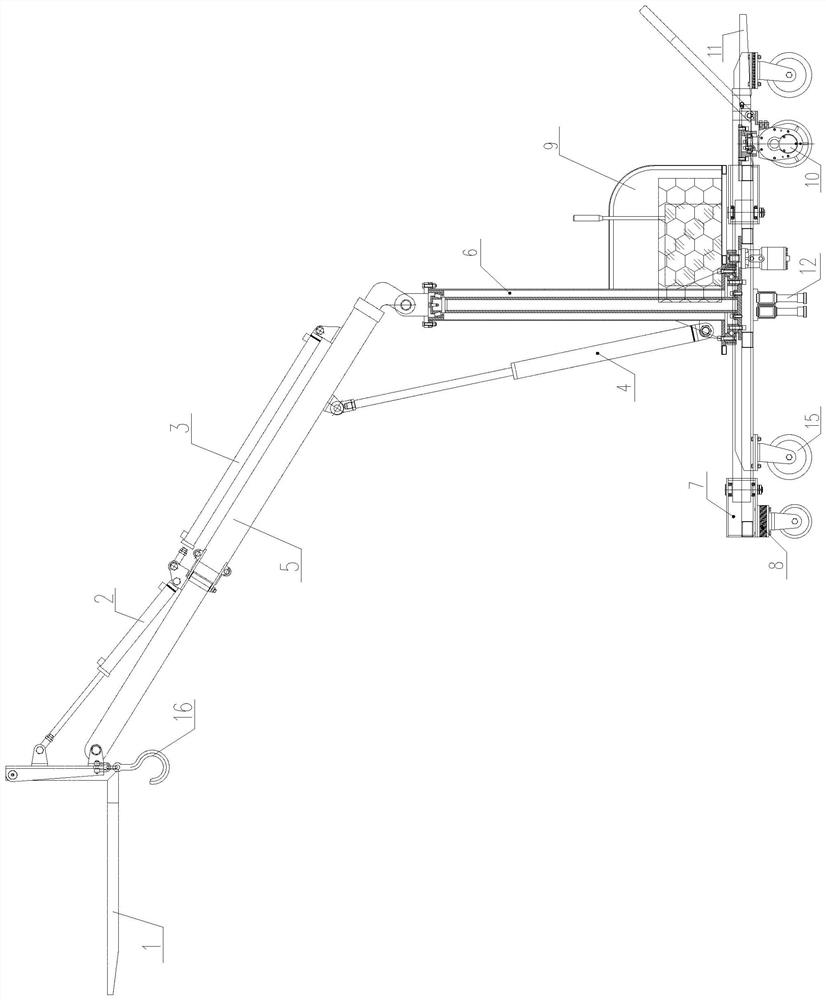

[0038]Embodiment 1: A dual-purpose loading and unloading machine for forks and cranes, including a hydraulic system, a cantilever mechanism 5, a column mechanism 6, and a car body mechanism 7. A fork 1 and a hook 16 are installed at one end of the cantilever mechanism 5, and a fork 16 is installed at the other end. On the column mechanism 6, the column mechanism 6 is installed on the car body mechanism 7, and the cantilever mechanism 5 is equipped with a hydraulic system that controls the expansion and contraction of the cantilever and maintains the level of the fork 1, and the cantilever mechanism 5 realizes up and down under the control of the hydraulic system. Swing and stretching back and forth are convenient for taking out goods at different distances, and are also convenient for transporting goods; and the column mechanism 6 is provided with a rotating mechanism, which can rotate in the vertical direction to realize picking up goods at different positions. The loader integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com