Diamagnetic three-dimensional gear tripod head

A technology of pan/tilt and gear, which is applied in the direction of machine platform/support, supporting machine, mechanical equipment, etc. It can solve the problems of not meeting high precision requirements, angle offset, and low wear resistance of gears, so as to improve the accuracy of use , the effect of small adjustment stroke and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

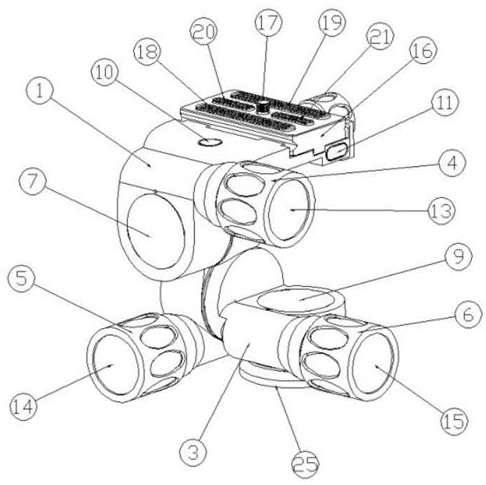

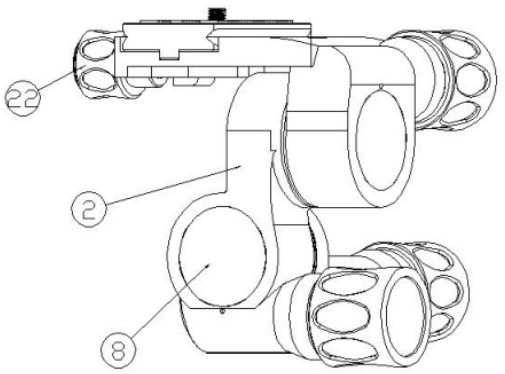

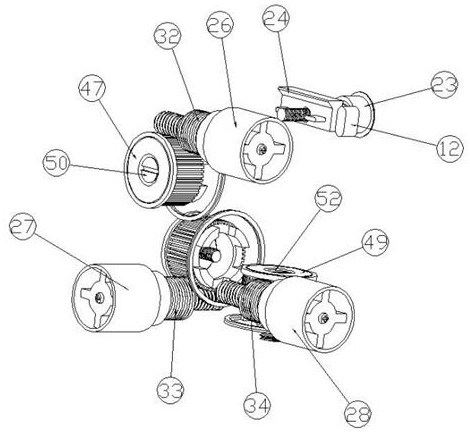

[0024] Such as Figure 1-Figure 6The shown antimagnetic three-dimensional gear platform includes a first housing 1, a second housing 2 and a third housing 3, and the inner sides of the first housing 1, the second housing 2 and the third housing 3 are respectively The first dial 7, the second dial 8 and the third dial 9 are fixedly installed, and the first turbine upper cover is respectively connected to the first dial 7, the second dial 8 and the third dial 9 47. The second turbine upper cover 48 and the third turbine upper cover 49, the first turbine upper cover 47, the second turbine upper cover 48 and the third turbine upper cover 49 are respectively connected with the first turbine 44 and the second turbine 45 and the third worm wheel 46, and the inside of the first worm wheel 44, the second worm wheel 45 and the third worm wheel 46 are threadedly connected with a first lock worm screw 50, a second lock worm screw 51 and a third lock worm screw 52, the first The lock tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com