A kind of permeable concrete and its construction method

A technology of permeable concrete and construction methods, which can be applied to cohesive pavements, roads, gutters/curbs and other directions paved on site, and can solve the problems of low compressive strength of permeable concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

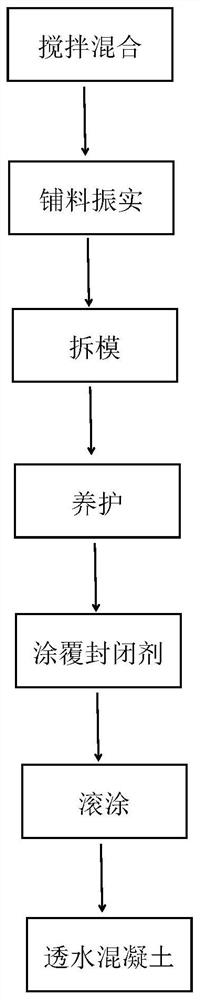

[0051] refer to figure 1 , a construction technique of permeable concrete, comprising the following steps:

[0052] S1: Stir to mix. Transport 15 kg of crushed stone and 4.75 kg of cement in parts by weight to a concrete mixer for mixing and stirring, and keep stirring for 1.5 minutes to form a first mixture. Then, 1.2 kg of water was added to the first mixture, and the addition was divided into three times, with an interval of 10 seconds between each time. After the last water addition was completed, the mixture was continuously stirred and mixed for 5 minutes to form the second mixture. Among them, the cement is Portland cement, and the crushed stone is made of crushed stone with a particle size of 4.75-9.5mm.

[0053] S2: The spread material is vibrated. Pour the second mixture into the mold, and then the staff will spread the second mixture in the mold, and then tamp and level the second mixture in the mold, and control the loosening coefficient within the range of 1.10...

Embodiment 2

[0060] The difference from Example 1 is that in step S3, the mold is removed after the material treated in S2 lasts for 8 days.

[0061] S4: Conservation. The material after S3 treatment was maintained continuously for 30 days; water was sprinkled on the material every day, and the plastic film was immediately covered after watering. After curing, polish and clean the floating slurry on the surface of the material.

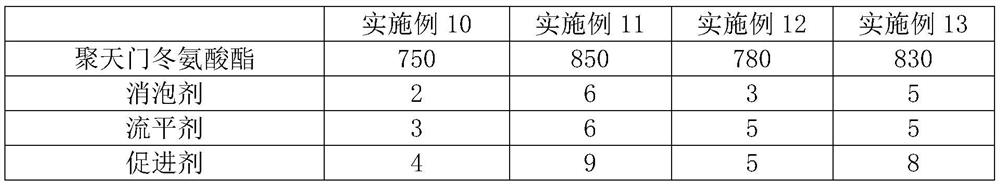

[0062] In step S6, each material of component A of polyurea includes 800 parts of polyether polyol, 150 parts of crosslinking agent, 4 parts of defoamer, and plasticizer by weight of each material of component A of polyurea. 45 parts, 4 parts of anti-ultraviolet agent and 4 parts of antioxidant.

[0063] Among them, the polyether polyol is polyoxypropylene glycol, the crosslinking agent is cyclohexane dimethanol, the defoamer is polydimethylsiloxane, the plasticizer is dioctyl terephthalate, and the anti-ultraviolet agent is The UV-531 ultraviolet absorber sold...

Embodiment 3

[0065] A construction technique for permeable concrete, comprising the following steps:

[0066] S1: Stir to mix. Transport 15 kg of crushed stone and 4.75 kg of cement in parts by weight to a concrete mixer for mixing and stirring, and keep stirring for 1.5 minutes to form a first mixture. Then, 1.2 kg of water was added to the first mixture, and the addition was divided into three times, with an interval of 10 seconds between each time. After the last water addition was completed, the mixture was continuously stirred and mixed for 5 minutes to form the second mixture. Among them, the cement is Portland cement, and the crushed stone is made of crushed stone with a particle size of 4.75-9.5mm.

[0067] S2: The spread material is vibrated. Pour the second mixture into the mold, and then the staff will spread the second mixture in the mold, and then tamp and level the second mixture in the mold, and control the loosening coefficient within the range of 1.10-1.15, using plate v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com