Twelve-sector two-level PWM rectifier fault-tolerant control method based on genetic algorithm

A genetic algorithm and fault-tolerant control technology, which is applied in the field of fault-tolerant control of twelve-sector two-level PWM rectifiers, can solve problems such as poor fault-tolerant compensation effects, inability to separate, and inability to achieve optimal proportional compensation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0125] As a preferred embodiment, the present invention realizes the control method based on the form of DSP+FPGA, wherein the DSP is used to collect the reference voltage vector and transmit it to the FPGA, and then the FPGA determines the optimal basic voltage vector action time based on the genetic algorithm and transmits it to the DSP, and finally The DSP determines the switching tube PWM pulse according to the optimal basic voltage vector action time, and controls the switching tube on and off, specifically:

[0126] The clock frequency is 150MHz, the high-performance 32-bit floating-point central processor TMS320F28335 is the main controller, and the sampling circuit is controlled to collect the reference voltage vector angle in real time, and the data is transmitted through the connection between RS232 and FPGA. The baud rate is 115200. Work mode, sending mode as shown in Table 3:

[0127] Table 3 Angle sending method

[0128]

[0129] Select Terasic Alter FPGA DE2-...

Embodiment

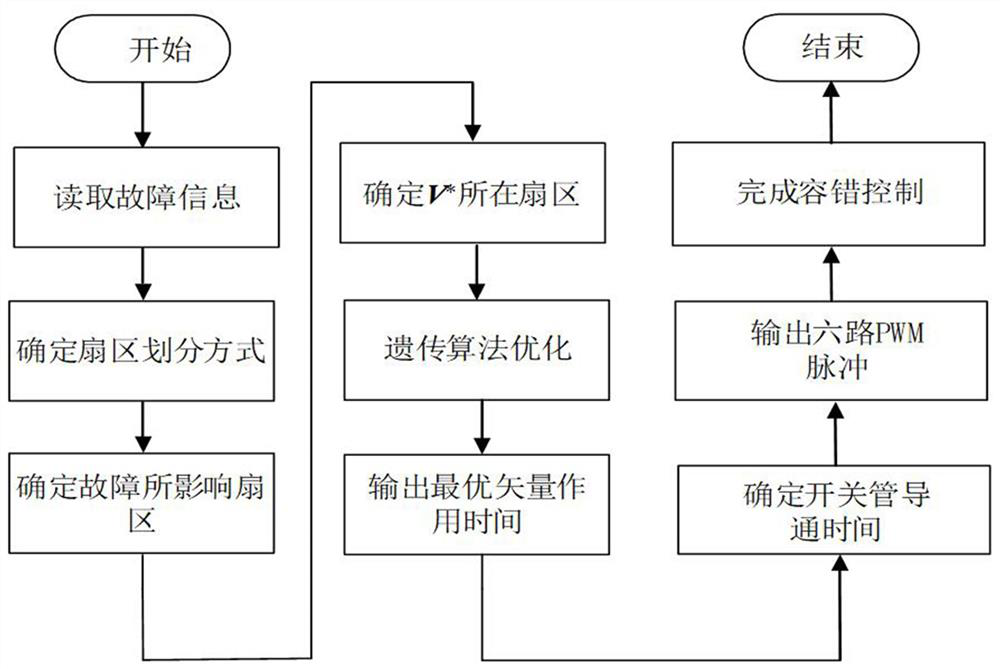

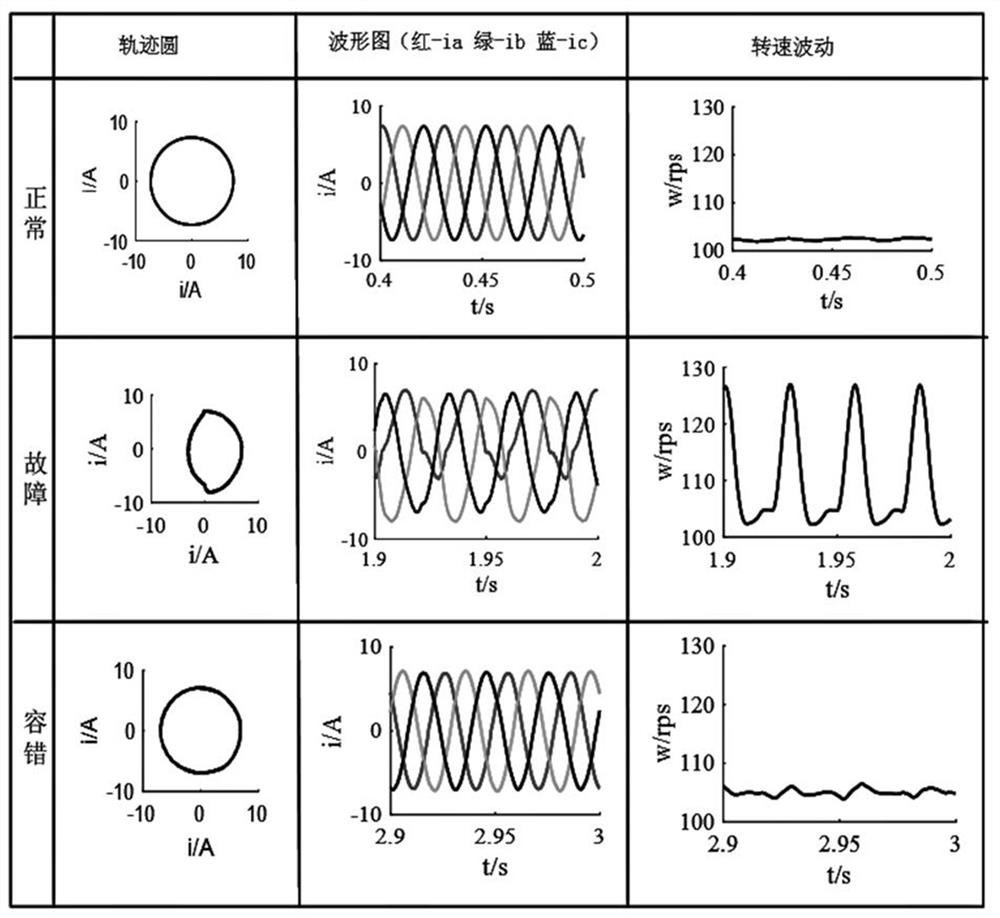

[0144] In order to verify the effectiveness of the solution of the present invention, this embodiment mainly performs simulation analysis on the open circuit fault of the power switch tube S1, image 3 It is a system control flow chart, which specifically includes the following steps:

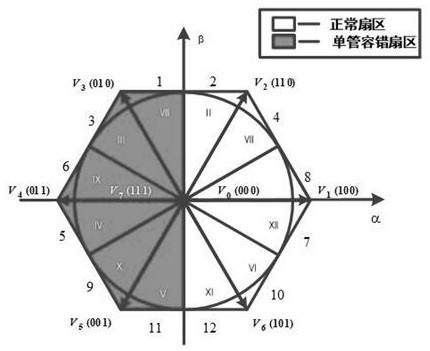

[0145] 1. Sector division: such as figure 2 As shown, when an open-circuit fault occurs in S1, the left half of the sector is affected.

[0146] 2. Data acquisition when the system is running: such as figure 1 As shown, firstly, for the permanent magnet synchronous generator abc three-phase current i a i b i c Sampling, the three-phase current angle θ is obtained through the encoder, and the current component i in the two-phase rotating coordinate system (dq) is obtained after coordinate transformation d , i q . i d , i q with a given i dref , i qref The deviation of U is obtained after the current loop control d , U q ; d and U q After coordinate transformation, the two-phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com