Motor protection type fire pump

A technology for motor protection and fire pumps, applied to electrical components, electromechanical devices, electric components, etc., can solve problems such as poor protection capabilities of fire pumps, achieve the effects of increasing pumping efficiency, increasing deformation, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

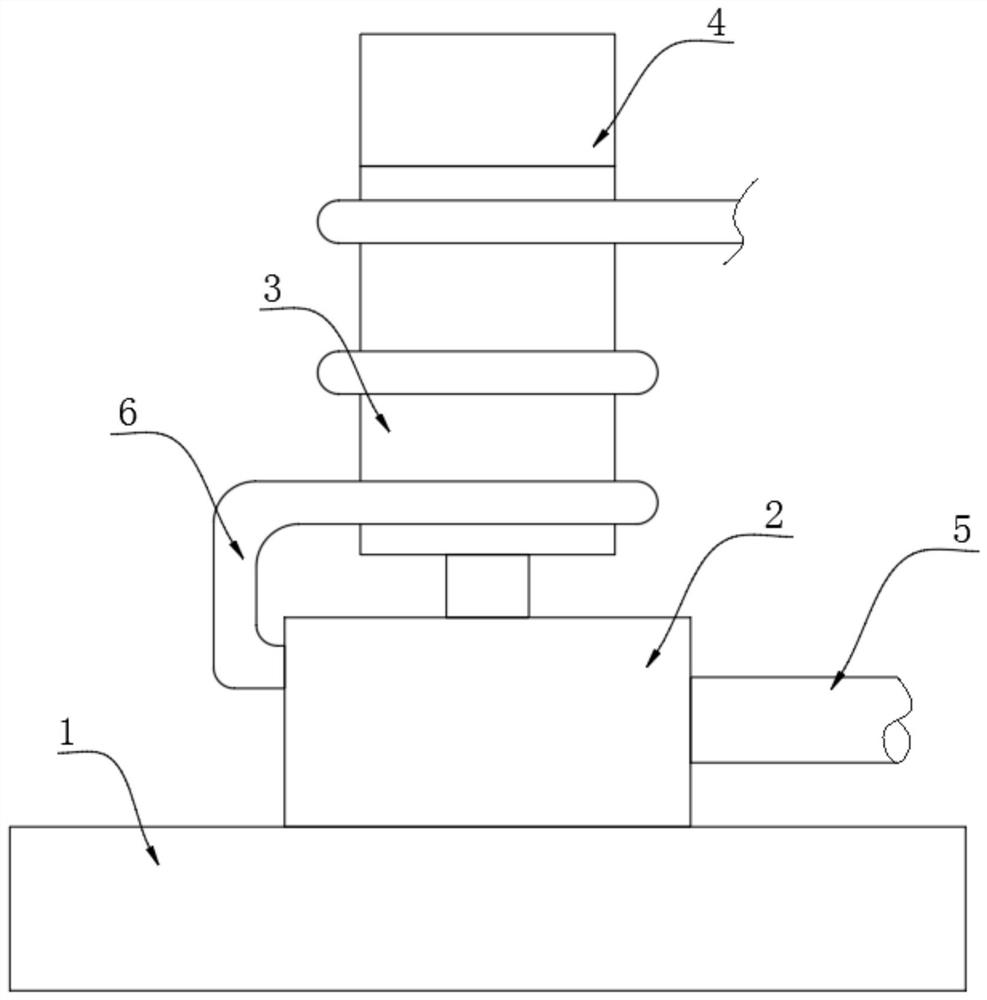

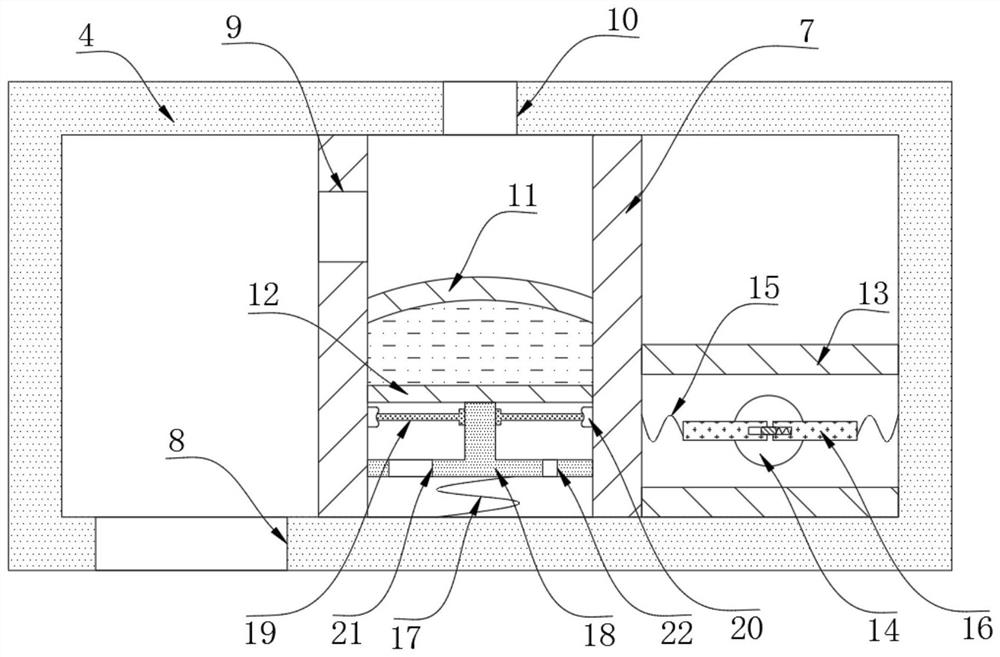

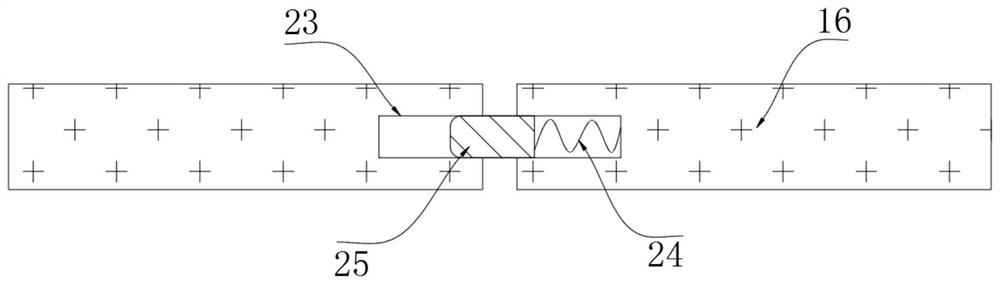

[0021] refer to Figure 1-3 , a motor protection type fire pump, including a base 1 and a pump body 2 and a motor 3, the end of the motor 3 is fixed with a cooling box 4, and the two ends of the pump body 2 are respectively fixed with a water inlet pipe 5 and a drain pipe 6, The drain pipe 6 is wound around the side wall of the motor 3, the inner wall of the cooling box 4 is fixed with a spacer 7, the side wall of the cooling box 4 is provided with a ventilation slot 8 communicating with the inside of the motor 3, and the side wall of the spacer 7 is penetrated with a The air intake hole 9 and the side wall of the cooling box 4 are provided with an exhaust hole 10, and a check valve is arranged inside the air intake hole 9 and the exhaust hole 10 to ensure the smooth pumping of the air flow. sheet 11, the inner wall of the cooling box 4 is fixed with two symmetrically arranged magnetic blocks 13, the inner wall of the cooling box 4 is fixed with two symmetrically arranged piez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com