Method for testing sealing integrity of medicine packaging container by improved color water intrusion method

A packaging container and water intrusion technology, which is applied in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, machine/structural component testing, etc. It can solve the problem that the sensitivity cannot continue to meet the requirements and the anti-interference ability is poor , interference detection and other issues, to achieve the effect of shortening the experimental cycle, strong anti-interference ability, and high specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] instrument

[0029] Sealing tester, MFY-05S, Jinan Sanquan Zhongshi Experimental Instrument Co., Ltd.

[0030] Fluorescence spectrophotometer, F-2710, Hitachi (China) Co., Ltd.

[0031] Electronic balance, XS205DU, METTLER TOLEDO

[0032] Ultrapure Water Meter, Milli-Q Reference, Millipore

[0033] materials

[0034] Sodium fluorescein, P1605648, Adamas-beta

[0035] Sodium Hydroxide, C10921846, 96%, MACKLIN

[0036] Capillary, Shanghai Zhonglin Electromechanical Equipment Co., Ltd.

[0037] Steps

[0038] positive sample preparation

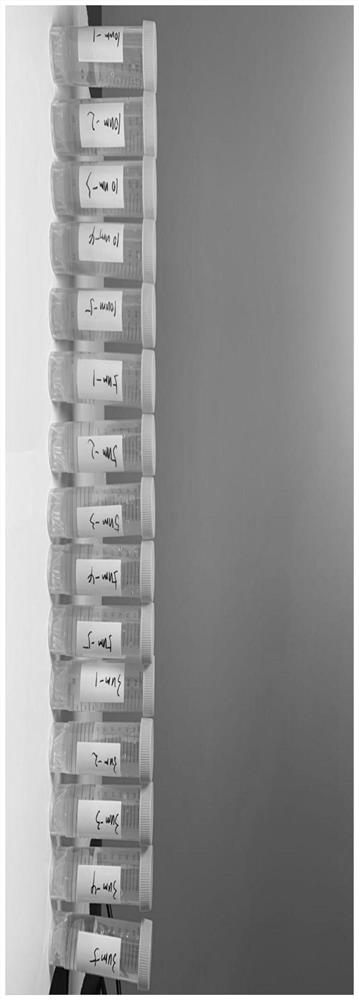

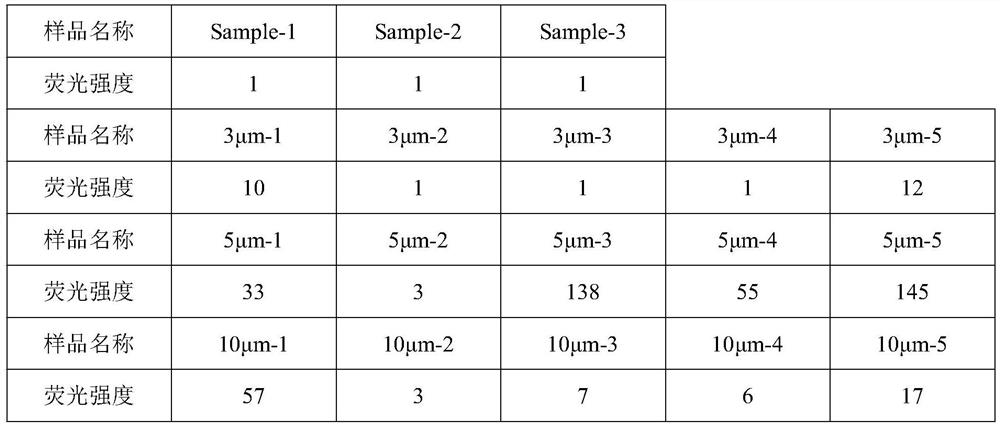

[0039] Take 15 sterile powders for injection (12mL specification) and divide them into a 3 μm positive sample group (5), a 5 μm positive sample group (5), and a 10 μm positive sample group (5). Remove the labels and plastic covers from the above samples, and clean the outer surface with ultrapure water. Use a capillary with a corresponding pore size to penetrate the rubber stopper through a stainless steel needle, pull out the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com