Phosphorus tank top-mounted anti-adhesion liquid level meter

A liquid level gauge, top-loading technology, applied in the field of phosphorus chemical industry, can solve the problems of burning corrosion of elemental phosphorus, burning damage of yellow phosphorus, affecting the movement of the float rod, etc. Effect of pulling operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

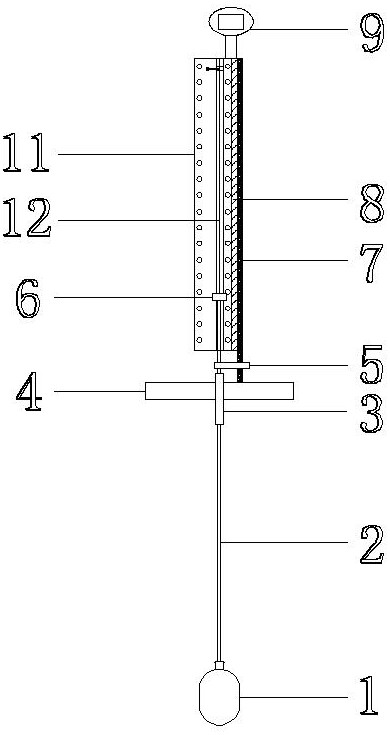

[0042] Such as Figure 1-4 As shown, the first embodiment of the present embodiment includes the detection mechanism, mounting and guiding mechanism, and the liquid level meter, and the liquid level meter is provided. The traction device for the detection mechanism moves up and down, the specific structure is as follows:

[0043] The detecting mechanism includes floating balls 1 and floating ball 2, floating ball 1 is a hollow sphere, and is a circular cylinder of both ends. The longitudinal section is intermediate rectangle of both ends, and the lateral cross section is circular; floating The lower end portion of the clip rod 2 is connected to the arc surface geometric center point of any of the floating ball 1; the connection of the float 1 and the floating ball 2 adds the internal thread sleeve 24 plus pin 25, wherein the internal thread sleeve 24 is set. At the upper end of the float 1 arc surface, fixed with the float 1, the floating ball 2 is in the inner thread sleeve 24, an...

Embodiment 2

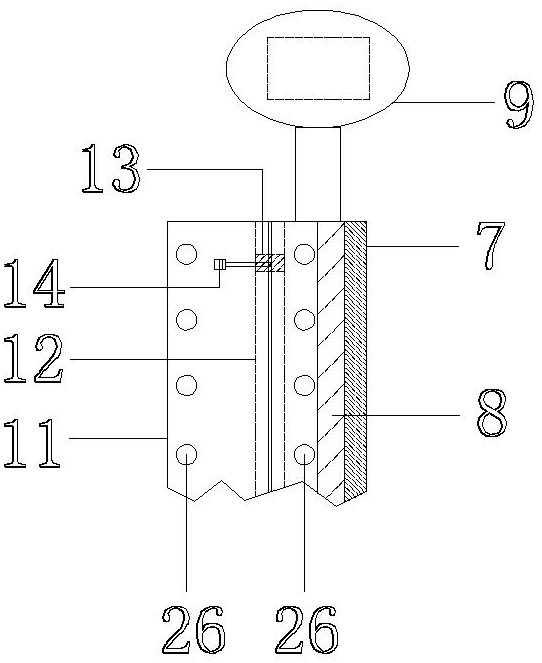

[0048] Such as Figure 5 , 6 As shown, the first embodiment of the present embodiment includes a detection mechanism, mounting and guiding mechanism, and a liquid level meter, from the bottom to the upper to the upper, and the liquid level meter, in which the mounting and guiding mechanism and liquid The traction device of the detection mechanism is set between the position of the body, and the specific structure is as follows:

[0049] The detecting mechanism includes floating balls 1 and floating ball 2, floating ball 1 is a hollow sphere, and is a circular cylinder of both ends. The longitudinal section is intermediate rectangle of both ends, and the lateral cross section is circular; floating The lower end portion of the club 2 is connected to the arc surface geometry center point of any of the floating ball 1; the connection of the float 1 and the floating ball 2 uses a threaded connection, and the reverse thread is provided in the contact position of the two. Anti-lactor 23....

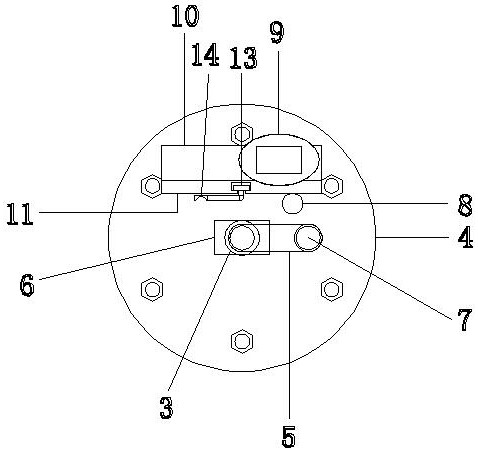

Embodiment 3

[0057] Such as Figure 7 As shown, the first embodiment of the present embodiment is a substantially consistent with the structure described in Example 2, and the arrangement position of the remote transmission 9 is in the sleeve 19. Central.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com