Burner fire cover and gas cooker using the fire cover

A burner and fire cover technology, applied in the direction of burners, gas fuel burners, applications, etc., can solve the problems of unfavorable stove combustion efficiency, high requirements for stove dampers, and high air velocity, so as to reduce the blockage of fire transmission grooves probability, better fire transmission performance, and enhanced applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

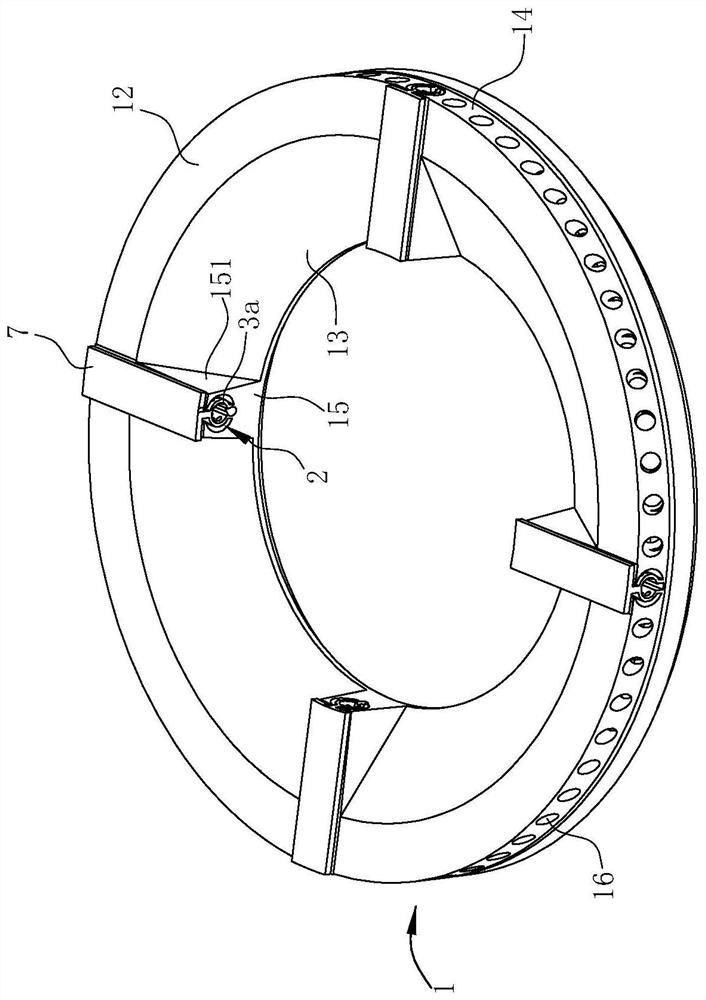

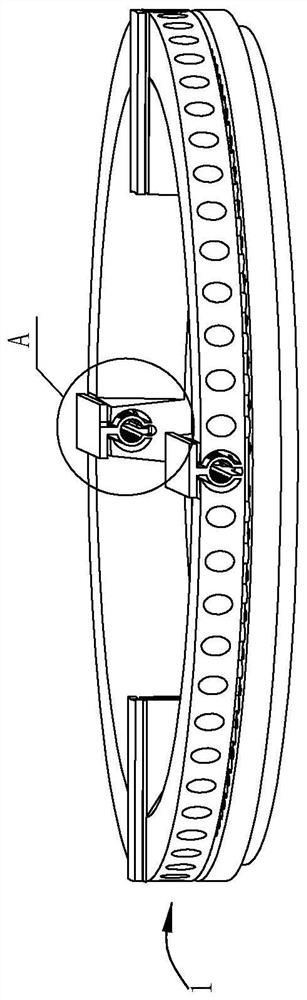

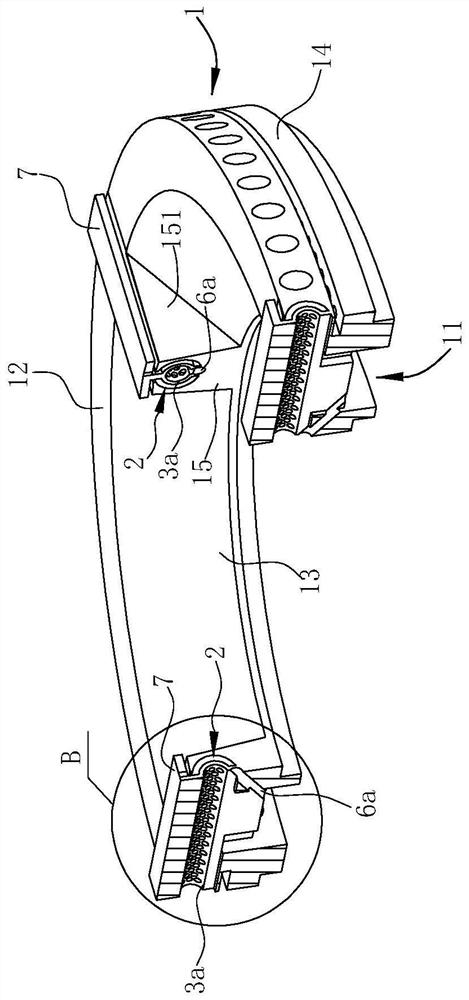

[0040] like Figure 1 ~ 7 As shown, the combustor fire cover of the preferred embodiment includes a circular cover body 1, which is provided in a fire groove 2 at the top of the fire cover body 1, and the separator 3a, which is provided in the fire groove 2, and The cover plate 7 above the fire. In this embodiment, four of the fire grooves 2 have four in the center of the fire cover body 1 in the top of the fire cover body 1, and the length direction of the fire cover 2 along the radial direction of the fire cover body 1, each The flow of fire grooves 2 corresponds to a cover plate 7, a partition member 3a, which is described hereinafter in which one of the flux 2 is described. In this paper, "within" refers to the center of the fire cover body 1, "outside" refers to the center of the fire cover body 1.

[0041] like Figure 1 ~ 4 As shown, the fire cover body 1 includes an annular top wall 12 and an inner ring wall 13 and an outer ring wall 14 that extend vertically or inclined dow...

Embodiment 2

[0052] like Figure 8 ~ 14 As shown, the difference from Embodiment 2 and Example 1 is that the partition member 3b and the convex groove 2 are different, and the separator 3b of the present embodiment is in a plate shape, and the longitudinal section of the wireless groove 2 is in type C.

[0053] In the present embodiment, the separator 3b is vertically disposed, and the upper end extends the transfer fluid groove 2 is connected to the cover plate 7, and such a transmitting groove 2 is separated from the partition 3b in two regions in the width direction, The two regions are located on both sides of the separator 3b, and the through hole 31b penetrates the wall thickness of the separator 3b. Thus, both sides of the spacer 3b are integrated and independently, the small holes (ie, through holes 31b) have a steady effect, the effect is best, so that the fire is more smooth and the wind does not affect the wind, and can be bilateral Supplement of secondary air, double-sided fire, mor...

Embodiment 3

[0056] Example 3 is a gas stove having a fire cover of Example 2:

[0057] like Figure 15 , 16 As shown, the cooker further includes a base 0 and an inner ring flam cover 8, and the fire cover body 1 is enabled outside the inner ring cover 8 and forms an annular passage 81 between the two, and an ignition needle 9 is provided in the annular passage 81. There are two discharge electrodes 91 of the ignition needle 9, and the two discharge electrodes 91 points to the inner ring flakes 82 and the inner ring fire hole 8 of the inner loop fire cover 8, even if one of the discharge electrodes 91 is poor, the other is also Can work for ignition.

[0058] The fire cover body 1, the inner ring fire 8, and the ignition needle 9 are all set on the base 0, which is prior art, and details are not described herein again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com