Method and system for determining yielding support opportunity of hard rock deep vertical well shaft

A determination method and wellbore technology, which are applied in vertical shaft equipment, earthwork drilling, complex mathematical operations, etc., can solve the problems of complicated calculation, stay, and difficulty in determining the initial and final deformation of surrounding rock radial, and achieve easy programming, The effect of reducing dosage and improving design safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

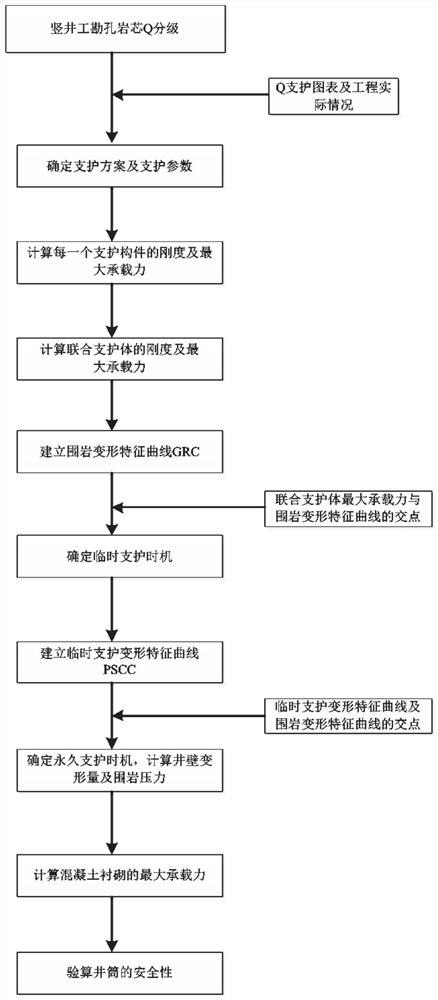

[0032] In a typical implementation of the present invention, this embodiment discloses a method for determining the timing of yielding support of a hard rock deep vertical wellbore, and the specific process is as follows.

[0033] S1: if figure 2 , 3 , arrange survey holes within 25m around the vertical shaft, one or more can be arranged, use the vertical shaft survey holes, from top to bottom, use the internationally accepted Barton rock mass quality classification method (Q classification method) to classify each wellbore The surrounding rock in the construction section is graded for rock mass quality, and the wellbore support method and parameters in each construction section are determined by using the Q support chart and combining with the actual project, such as the length of anchor rods, the distance between anchor rods, and the thickness of shotcrete.

[0034] S2 as Figure 4 , for each support component of temporary support in each construction section, such as anc...

Embodiment 2

[0069] In a typical implementation of the present invention, this embodiment discloses a system for determining the timing of support for hard rock deep vertical wellbore yield pressure, including the following modules:

[0070] The first module is configured to obtain the support stiffness and maximum bearing capacity of the joint support body;

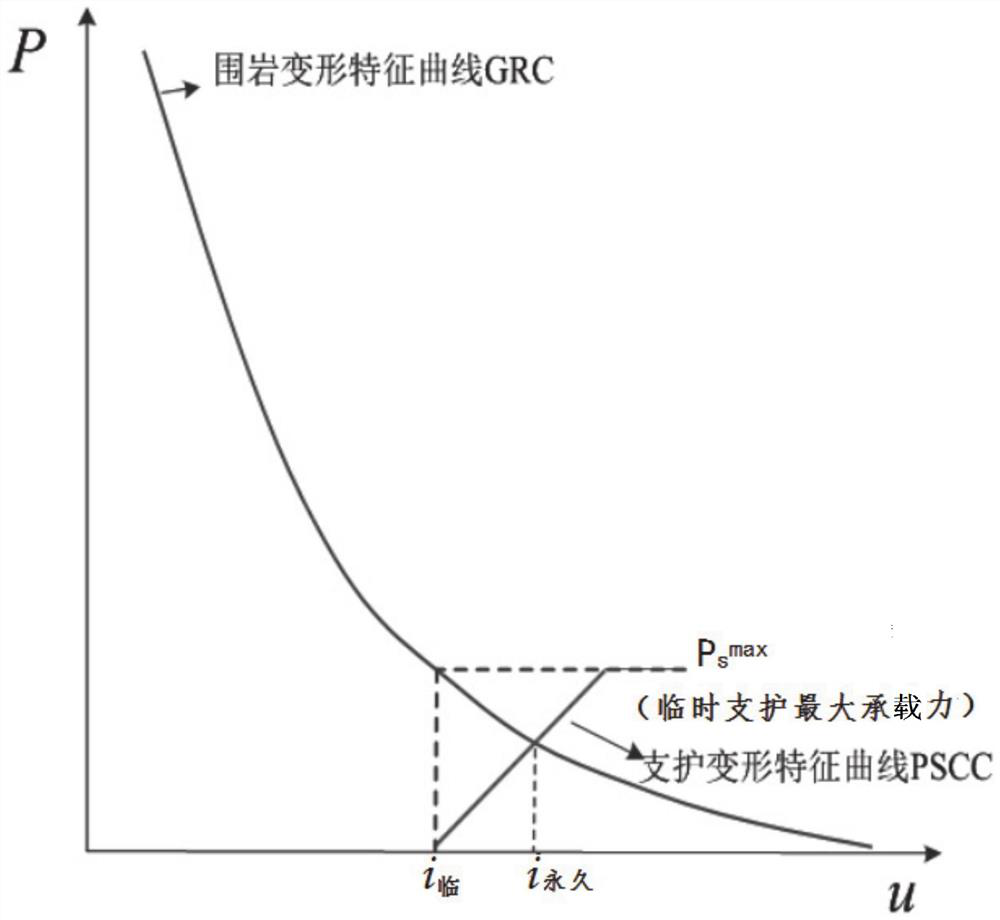

[0071] The second module is configured to establish the deformation characteristic curve PSCC of the temporary support body and the deformation characteristic curve GRC of the wellbore surrounding rock;

[0072] The third module is configured to collect the intersection point of the deformation characteristic curve PSCC of the temporary support body in the second module and the deformation characteristic curve GRC of the wellbore surrounding rock, and obtain the maximum bearing capacity of the joint support body on the deformation characteristic curve GRC of the wellbore surrounding rock the corresponding point;

[0073] The fourth ...

Embodiment 3

[0078] In a typical implementation of the present invention, this embodiment discloses a computer-readable storage medium, which stores a plurality of instructions, and the instructions are suitable for being loaded by a processor of a terminal device and executing the method described in Embodiment 1. A method for determining the timing of yielding support in deep vertical shafts in hard rock.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com