Coarse adjustment and fine adjustment combined pulse attenuator and pulse attenuation method

A combination of pulse attenuator and technology, which is applied in the field of pulp and paper making, can solve the problems of unsatisfactory effect and large fixed investment, achieve the effect of simple principle and equipment structure, improve paper performance, and attenuate pulp flow pressure pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

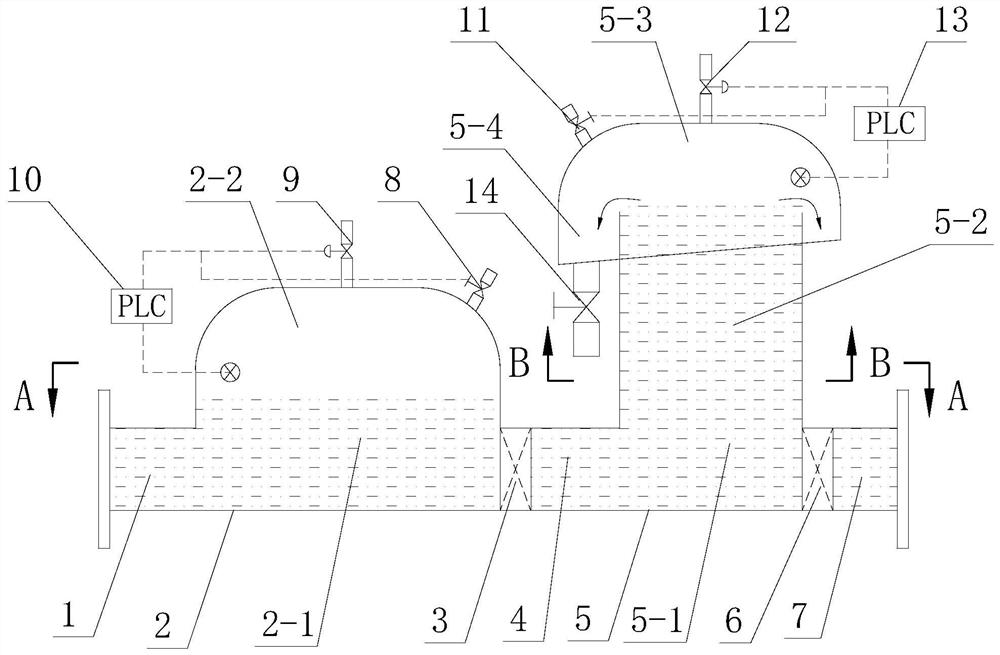

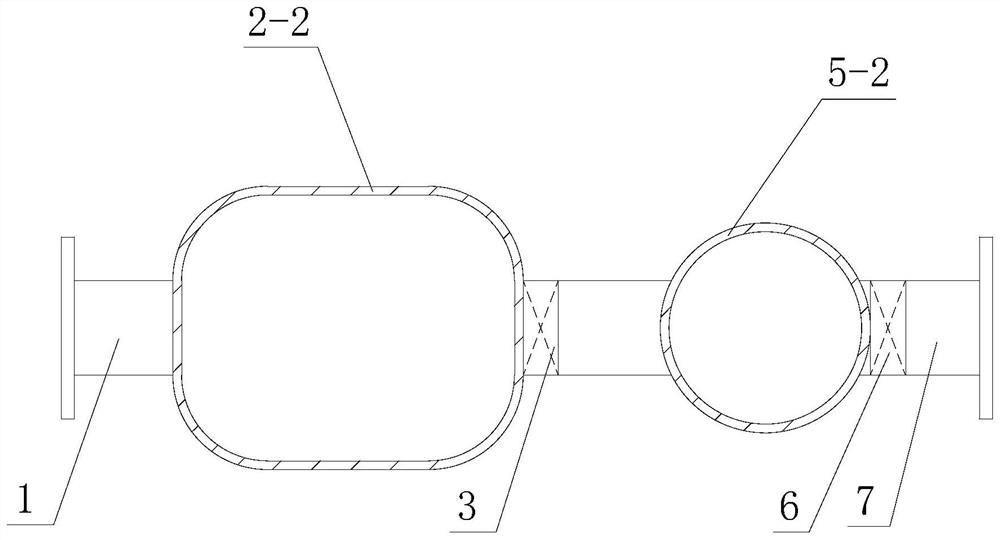

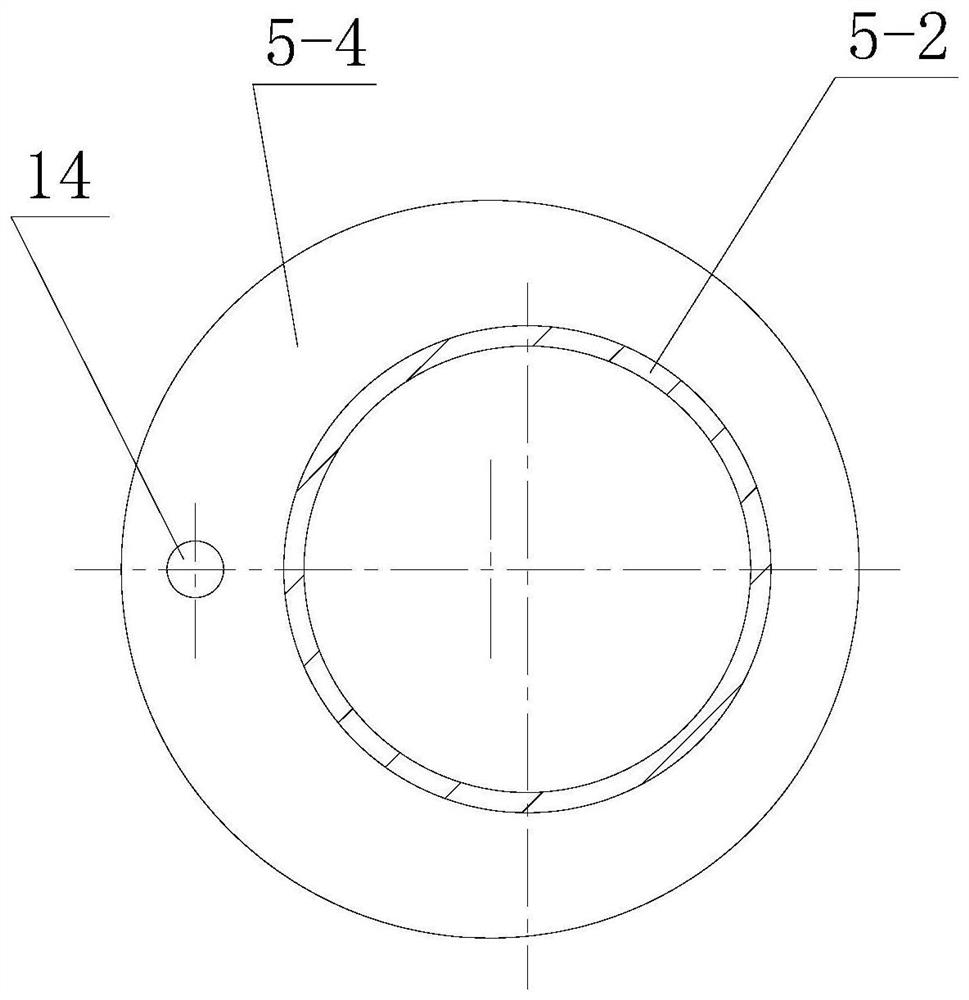

[0042] This embodiment is a pulse attenuator that binds to the fine adjustment, such as figure 1 or figure 2 As shown, including the puncturing tube 1, the coarse adjustment device 2, the first damping element 3, the connecting pipe 4, the fine tuning device 5, the second damping element 6, and the dried tube 7, and in the coarse tube 7. The first slurry flow passage 2-1 and the first air cushion chamber 2-2, the first air cushion chamber is connected to the first gas supply system, and the second slurry flow passage 5-1 in which sequential communication is provided in the fine tuning device. -2, the second gas mat 5-3 and the overflow chamber 5-4, the second gas supply system is connected to the second gas supply system. Among them, the coarse adjustment device and the first damping element form a first-stage attenuation pulse, the pulse generated by the slurry flows to the primary attenuation, the attenuation amplitude is large, the fine-tuning device and the second damping el...

Embodiment 2

[0057] The present embodiment is a pulse attenuation method which is coarse-conditioned and fine-tuning, and can be implemented by the pulse attenuator described in Example 1, including the following steps:

[0058] (1) The slurry is first entered into a coarse tuning device, and the first gas supply system passes into the first gas cushion. After the gas pressure in the first gas cushion chamber reaches the rated value, the gas pressure is stable in the first gas cushion. The slurry continuously passes through the first slurry flow path, and the pulse of the slurry flow through the volume of the gas cushion chamber is to achieve the purpose of eliminating the pulp flow pulse;

[0059] (2) After the slurry passes through the first slurry flow passage, the first damping element is first passed through the first damping element, and the first damping element places the speed pulsation of the slurry to the preliminary reflection and blocking effect, and then the slurry will enter the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com