Fruit wine deacidification strain and application thereof

A fruit wine and acidity technology, applied in the preparation of fungi, alcoholic beverages, microorganisms, etc., can solve the problems of uncoordinated wine body, no suitable strains, poor taste, etc., to improve aroma and flavor, reduce citric acid content, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

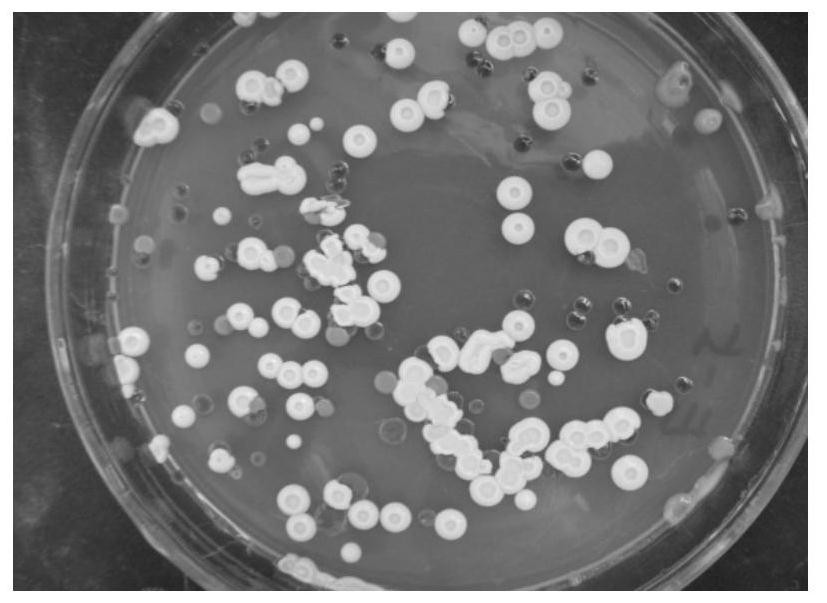

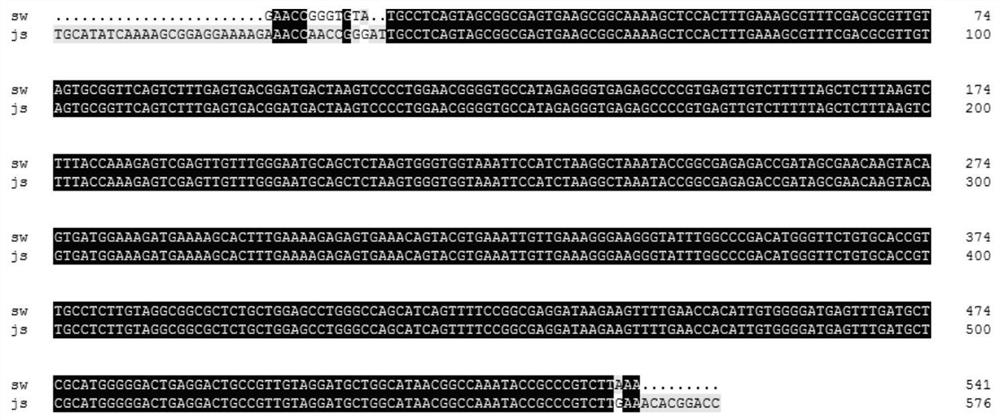

[0084] Example 1: Screening and identification of red bayberry fruit wine acid-reducing strains

[0085] Specific steps are as follows:

[0086] 1. Isolation, screening and purification of acid-reducing strains

[0087] (1) Accurate multi-point sampling Weigh samples (5.00g of water chestnut and Dongkui bayberry orchard soil, 2.00g of bayberry branches and leaves, and 10.00g of bayberry fruit), and place the obtained samples in 250mL conical flasks Add 100mL of physiological saline (0.9% NaCl solution) and a little glass beads, place them in a shaker at 30°C and 200r / min for about 2h, and let stand. Accurately draw 5mL of the supernatant and insert them into the pre-sterilized yeast enrichment medium (each 250mL Erlenmeyer flask contains 50mL of culture medium), and place it in a shaker at 30°C and 200r / min for 1 day. Obtain the pretreatment medium.

[0088] (2) The pretreated culture solution obtained in step (1) was left to stand and then serially diluted (10 -1 ~10 -6 ...

Embodiment 2

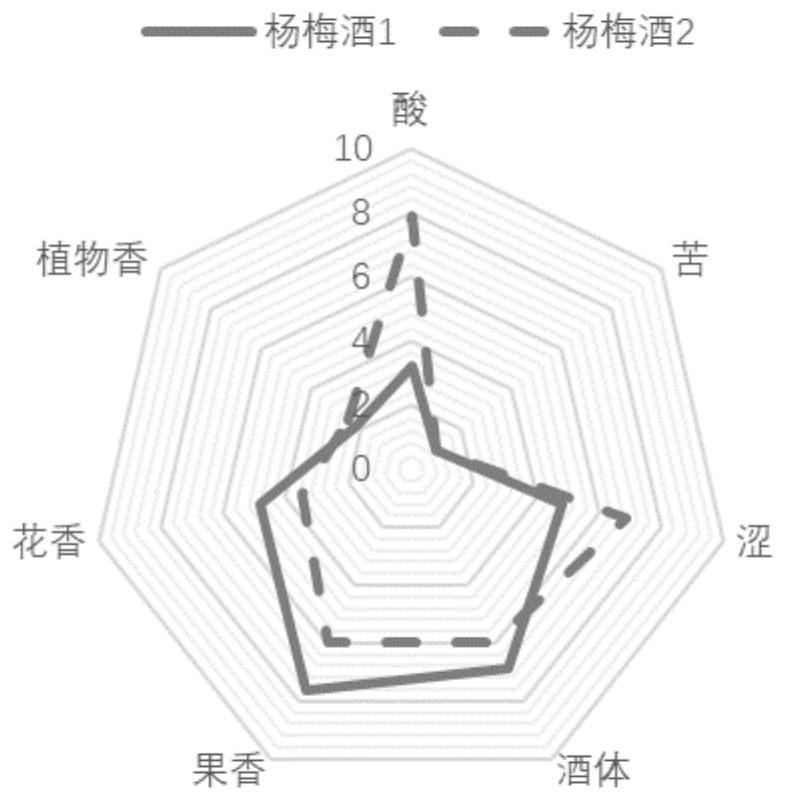

[0097] Embodiment 2: the brewing of bayberry fruit wine

[0098] The red bayberry fruit wine was brewed from the water chestnut variety bayberry in Xianju, Zhejiang, as the starting sample for biological acid reduction.

[0099] The brewing process of bayberry wine is as follows:

[0100] (1) Preparation of Candida diversa Z3 and Saccharomyces cerevisiae suspension

[0101] Preparation of Candida diversa (Candida diversa) Z3 bacterium suspension: the Candida diversa (Candida diversa) Z3 obtained in Example 1 was inoculated into YPD liquid medium, and cultivated at 30° C. to obtain a bacterial concentration of 1×10 6 cfu / mL bacterial suspension.

[0102] Preparation of Saccharomyces cerevisiae suspension: Inoculate Saccharomyces cerevisiae D254 into sucrose water with a mass fraction of 5%, and activate it at 37°C to obtain a bacterial concentration of 1×10 6 cfu / mL bacterial suspension;

[0103] (2) select fresh red bayberry fruit, crush and make red bayberry pulp broken l...

Embodiment 3

[0119] Embodiment 3: the brewing of blueberry fruit wine

[0120] Blueberry fruit wine was brewed from rabbit eye blueberries in Suzhou, Jiangsu Province, as a starting sample for biological acid reduction.

[0121] The brewing process of blueberry wine is as follows:

[0122] (1) select fresh blueberry fruit, crush to make blueberry pulp broken liquid;

[0123] (2) Primary fermentation: Inoculate the Candida diversa Z3 bacterial suspension obtained in step (1) of Example 2 into the above-mentioned broken blueberry pulp, and ferment at 20° C. for 24 hours;

[0124] (3) Enzyme treatment: add pectinase and SO2 (60mg / L) at a concentration of 30mg / L, and add sucrose until the total sugar content is 200g / L; after standing for 12 hours, crude fruit juice is obtained;

[0125] (4) Separation of skin dregs after fermentation: filtering the crude fruit juice mixture obtained in step (3);

[0126] (5) Secondary fermentation: Inoculate the Saccharomyces cerevisiae D254 bacterium suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com