Inverted tricycle frame

A tricycle and frame technology, applied to two-wheeled bicycles, motor vehicles, bicycles, etc., can solve the problems of high cost, complex structure, large production investment, etc., and achieve the effect of reducing cost, large investment, and high management cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

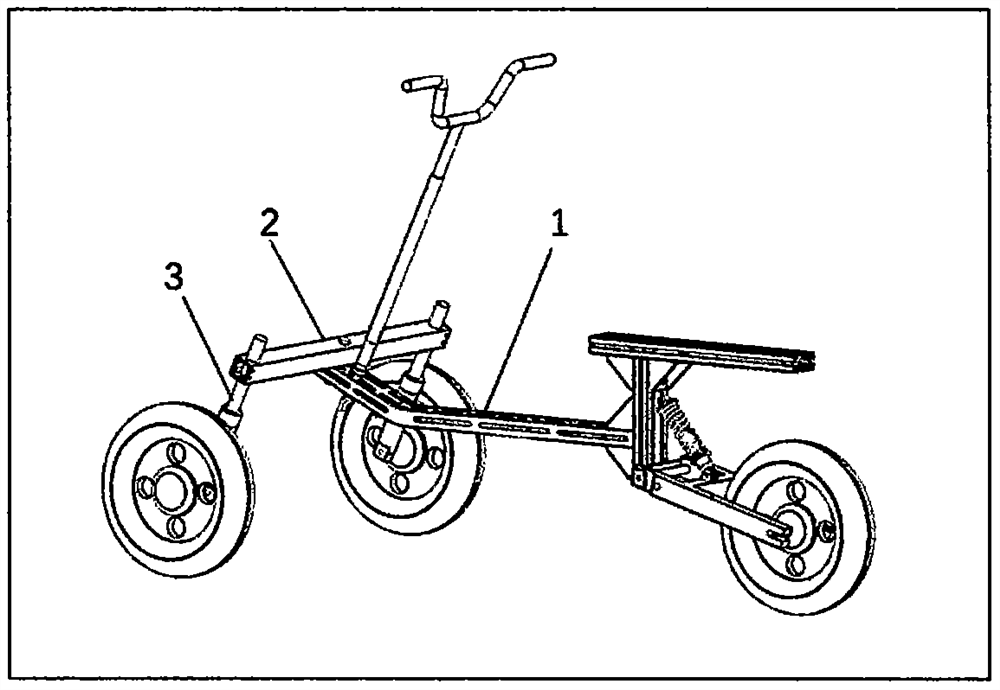

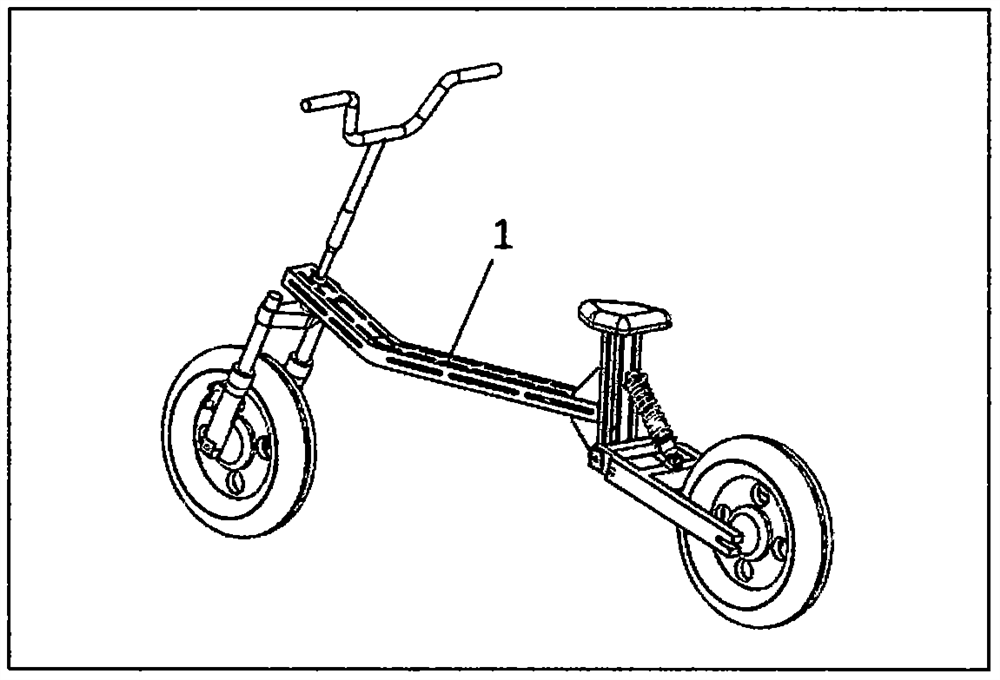

[0010] figure 1 It is a structural diagram of an inverted tricycle frame, the main part of which is made of profiles (1) through flexible connections or / and permanent fixed connections (non-welding), and one or / and more than one surface of the profiles (1) has a T shape Groove or / and bar-shaped grooves are convenient for connecting corresponding accessories. The profiles (1) for the frame body and frame accessories are materials that have undergone surface anticorrosion and beautification treatment. The profiles (1) for the frame body are selected according to the overall vehicle The design requires bending, cutting, and hole processing. Other accessories are flexibly connected or permanently fixed to the corresponding positions of the T-shaped grooves or bar-shaped grooves on the surface of the profile (1), so no special tooling is required to fix the position and location of the main parts and accessories. Welding, the entire frame no longer needs rust removal and surface tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com