Flame-retardant waterproof sound-absorbing plate manufacturing and processing process

A processing technology and technology of sound-absorbing panels, applied in metal processing, sound insulation, fire prevention, etc., can solve the problems that the production capacity cannot meet the specified requirements, the depth of the slot cannot be guaranteed, and the production qualification rate is affected, so as to save the processing time. Efficiency, avoiding displacement, increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

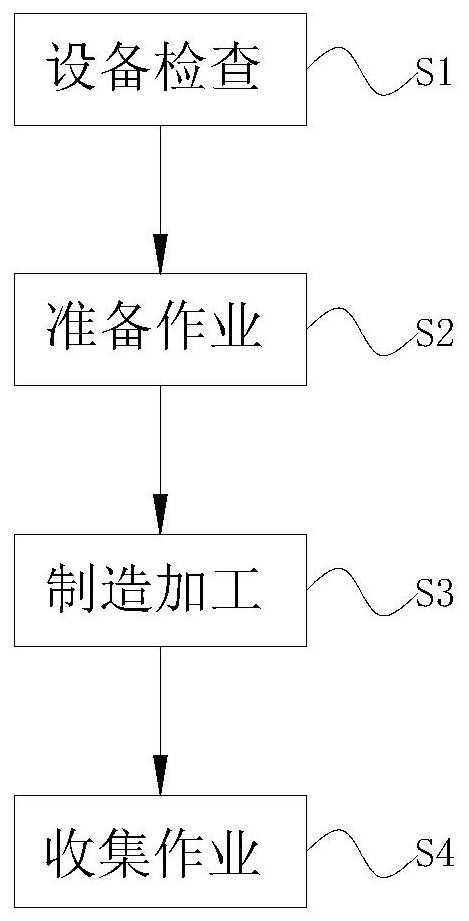

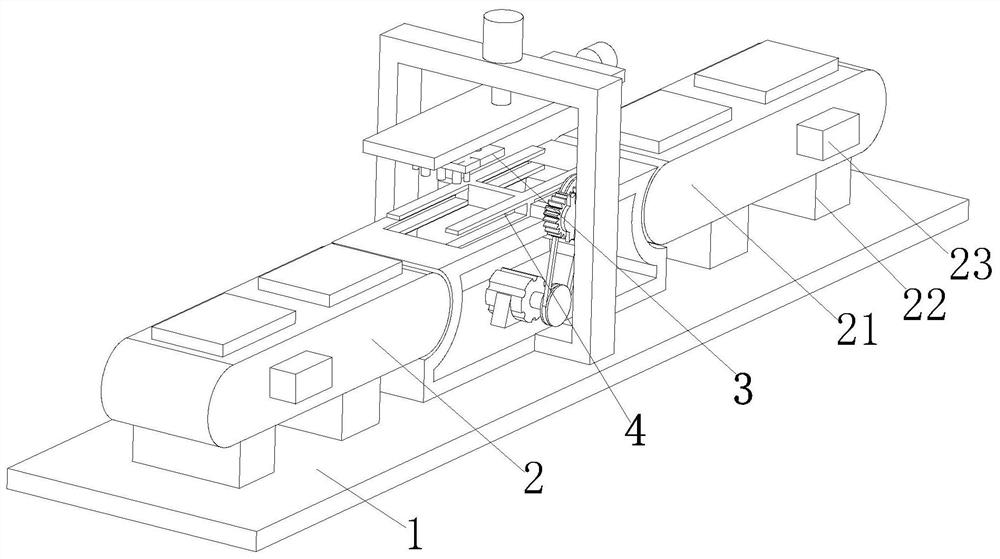

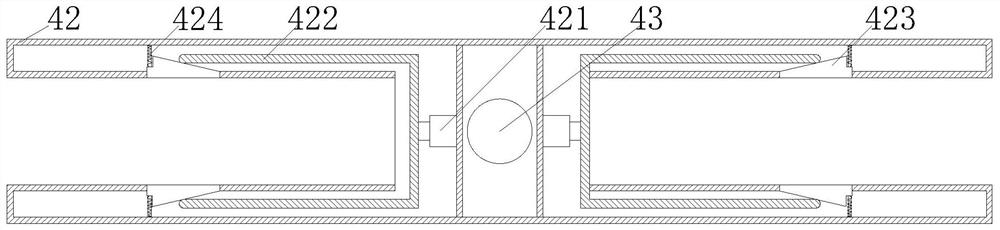

[0035] like Figure 1 to Figure 7 As shown in the figure, a manufacturing and processing process for a flame-retardant and waterproof sound-absorbing panel adopts a manufacturing and processing equipment for a flame-retardant and waterproof sound-absorbing panel. Device 2, processing device 3 and turning device 4, a conveying device 2 is fixedly installed on the bottom plate 1, a processing device 3 is fixedly installed at the position near the middle of the conveying device 2, and a turning device 4 is arranged below the processing device 3; The conveying device 2 drives the flame-retardant and waterproof sound-absorbing board to transport forward, and the turning device 4 fixes the flame-retardant and waterproof sound-absorbing board. The processing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com