Roll paper segmented cutting equipment for product processing

A cutting equipment and paper rolling technology, which is applied in metal processing and other directions, can solve the problems of too many operations, unable to roll paper, precise cutting of the cutting surface, long operation time, etc., and achieve the effect of blowing away

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

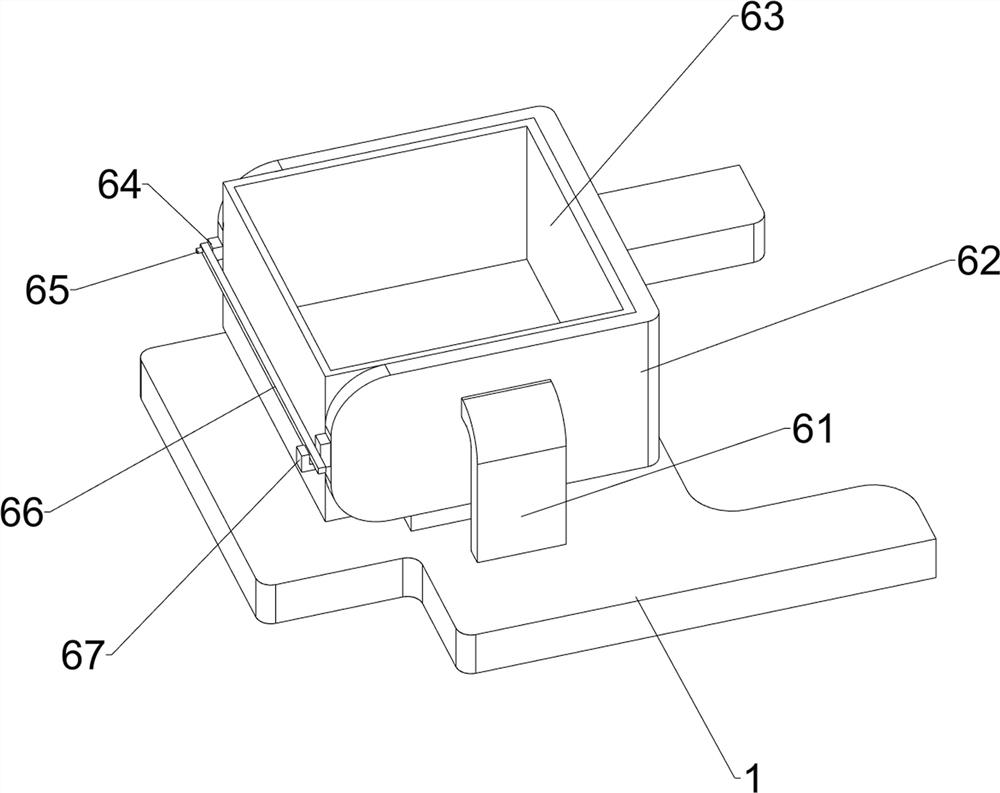

[0027] A roll paper section cutting equipment for product processing, such as Figure 1-Figure 4 As shown, it includes a base plate 1, a cutting mechanism 2 and a pushing mechanism 3, the base plate 1 is provided with a cutting mechanism 2, and the cutting mechanism 2 is provided with a pushing mechanism 3.

[0028] When people want to cut the roll paper into sections, they can use this kind of roll paper section cutting equipment for product processing. First, the user places the roll paper on the cutting mechanism 2, and then manually pushes the push mechanism 3 backwards. The roll paper is pushed backward, and the cutting mechanism 2 cuts the roll paper. After the roll paper is cut, the user pulls the push mechanism 3 forward to realize a reset action.

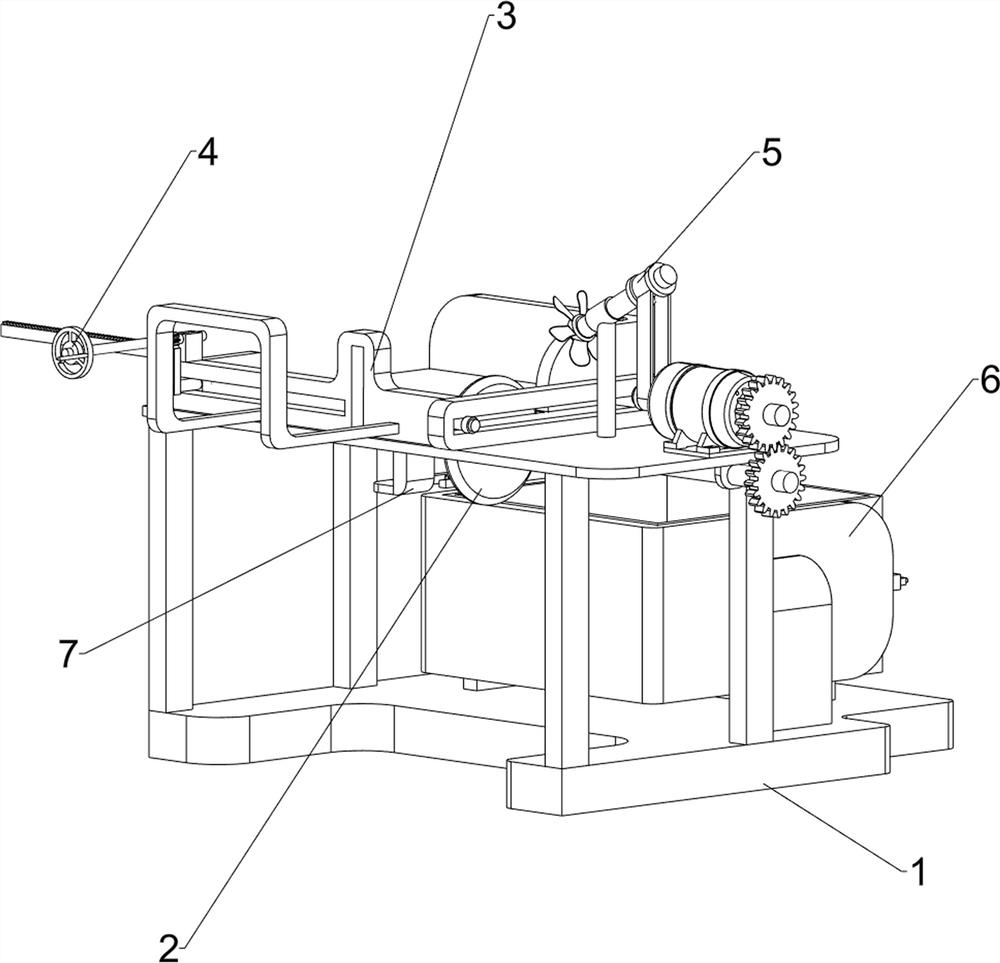

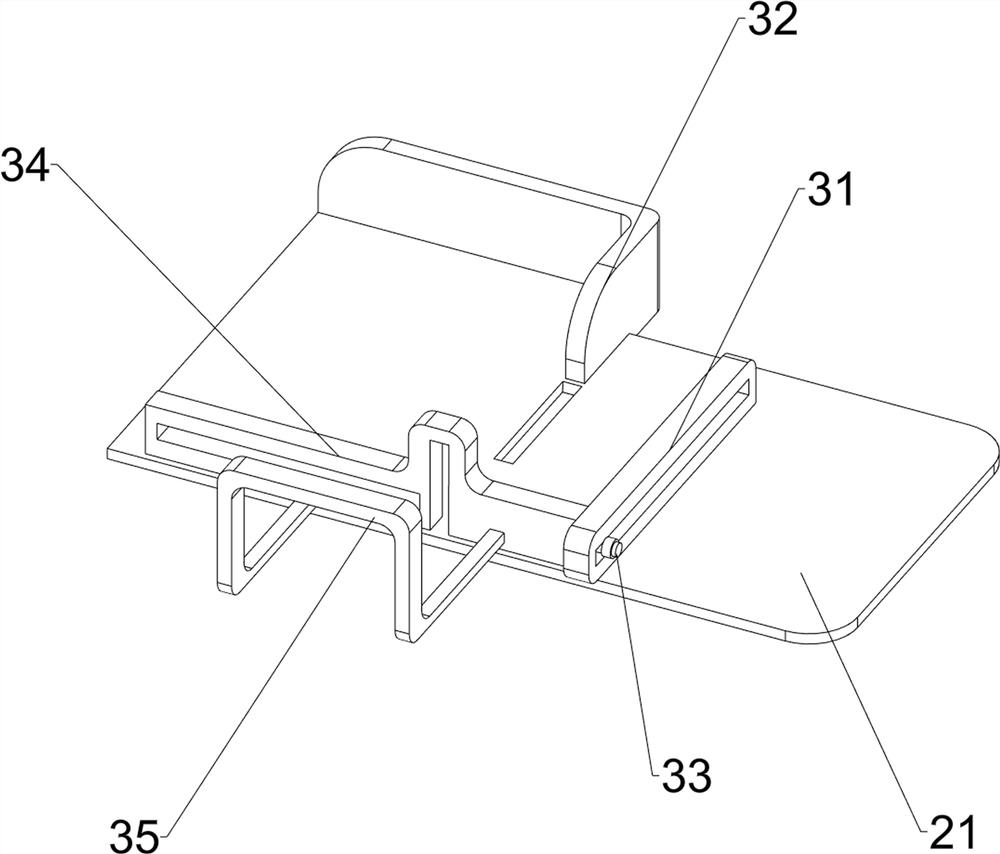

[0029] The cutting mechanism 2 includes a holding plate 21, a servo motor 22, a first fixed block 23, a first rotating shaft 24, a spur gear set 25 and a cutter 26, and the bottom plate 1 top is provided with a holding plat...

Embodiment 2

[0034] On the basis of Example 1, such as Figure 5-Figure 8 As shown, a pushing mechanism 4 is also included. The top of the front side of the holding plate 21 is provided with a pushing mechanism 4. The pushing mechanism 4 includes a second fixed block 41, a second rotating shaft 42, a spur gear 43, and a second push plate. 44, tooth bar 45, second slide bar 46 and rotating disk 47, the sliding type on the right side of holding plate 21 top is provided with the second push plate 44, and the second push plate 44 front side is provided with the second slide bar 46, and the second slide bar Rod 46 is connected with the sliding type of first slide bar 33 inner walls, and the right side of first slide bar 33 tops is provided with second fixed block 41, and second slide bar 46 is provided with rack 45, and second fixed block 41 tops rotatably set There is a second rotating shaft 42, a spur gear 43 is provided on the rear side of the second rotating shaft 42, and the spur gear 43 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com