A trajectory tracking system and method for industrial robots with neural network iterative compensation

An industrial robot and neural network technology, which is applied in the field of industrial robot trajectory tracking system and motion trajectory precision improvement system, can solve the problems such as unable to adjust parameters, achieve the effects of increasing convergence speed, realizing high-precision motion control, and improving motion trajectory accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0068] Embodiments of the present invention are as follows:

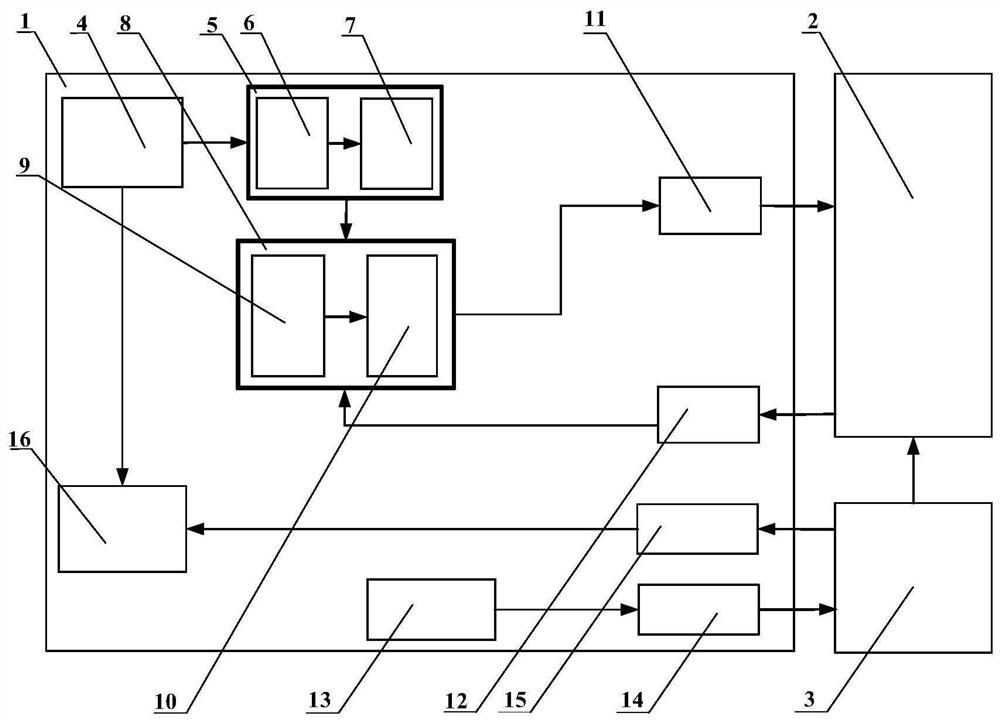

[0069] The specific implementation system is as figure 1 As shown, it includes industrial robot 2, measuring device 3 and track tracking system 1, track tracking system 1 is connected with industrial robot 2 and measuring device 3 respectively, industrial robot 2 is connected with measuring device 3, industrial robot 2, measuring device 3 and track The tracking system 1 jointly constructs a closed-loop industrial robot motion trajectory tracking system; the end flange of the industrial robot 2 is equipped with a moving target ball matched with the measuring equipment.

[0070] Trajectory tracking system 1 includes trajectory planning module 4, inverse solution compensation module 5, neural network PID module 8, robot input interface 11, robot output interface 12, measurement control modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com