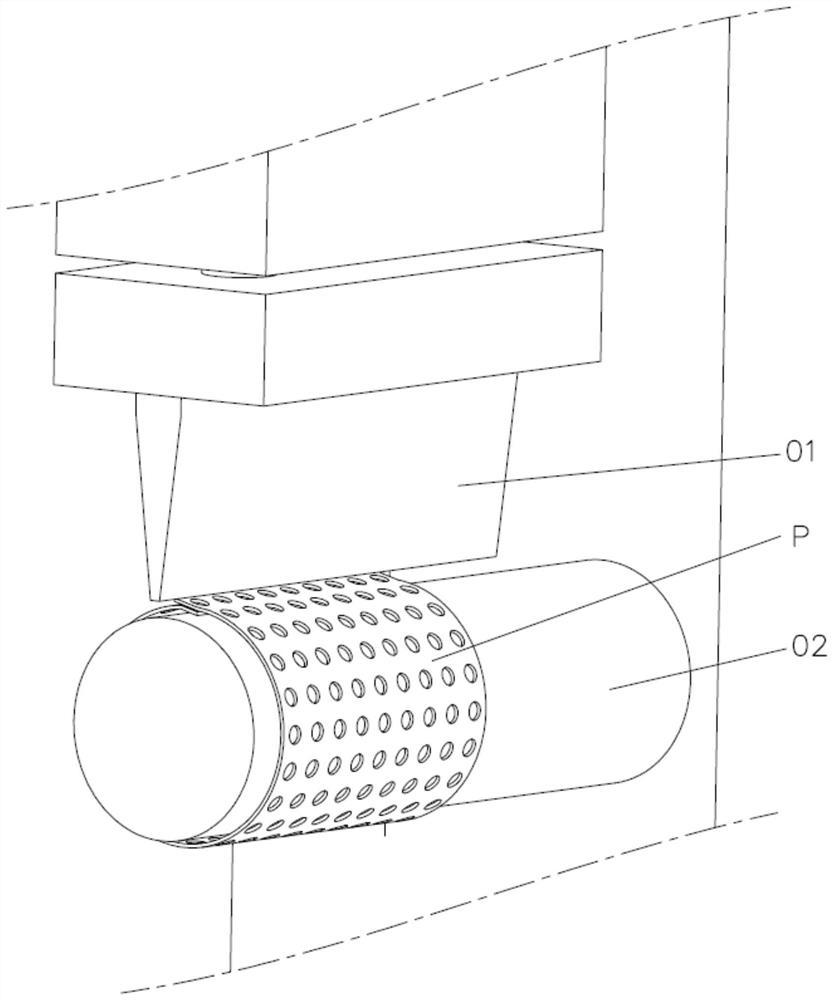

A method of manufacturing a cylindrical straight seam workpiece

A manufacturing method and cylinder technology, applied in manufacturing tools, metal processing equipment, resistance electrode bases, etc., can solve the problems of many processes, low production efficiency, low positioning dimensional accuracy, etc., and achieve accurate workpiece positioning, high production efficiency, Good welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

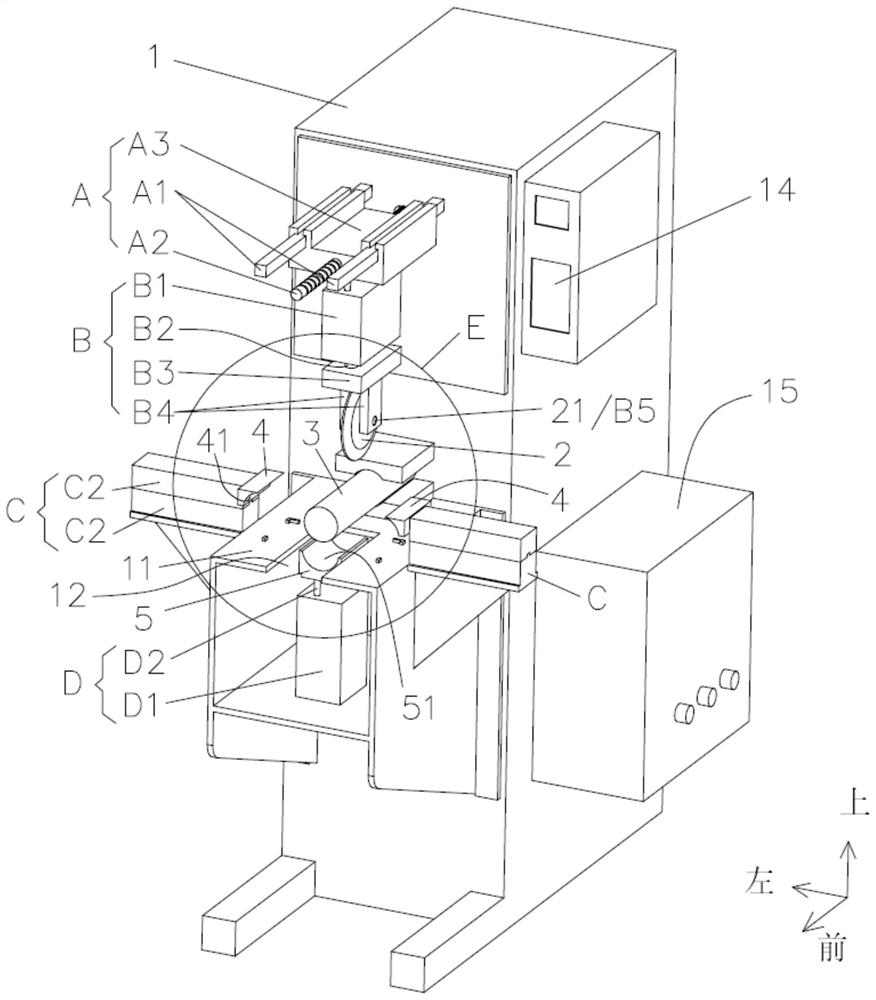

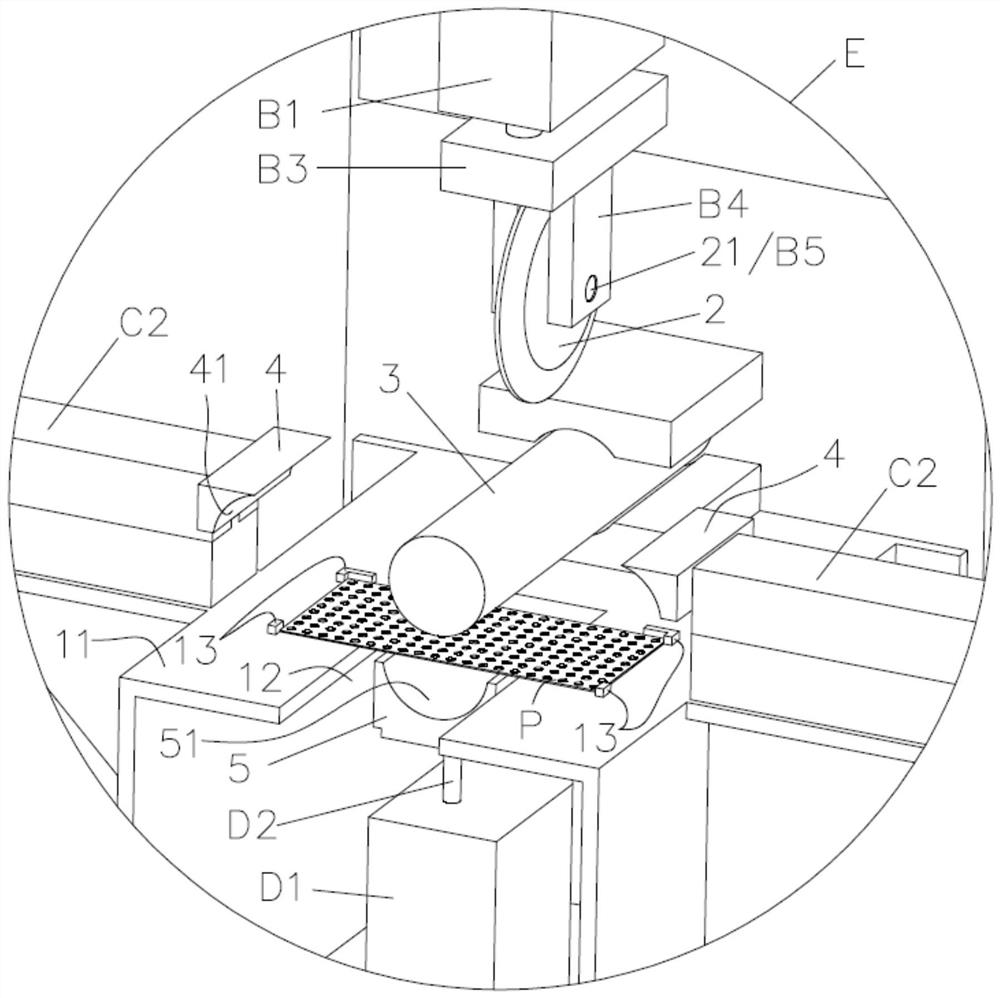

[0012] In order to further understand the features, technical means, specific objectives and functions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The descriptions of front, back, left, right, up, down, etc. in this paper are only relative relationships with reference to the positions of components shown in the drawings, and do not represent absolute limitations on the scope of protection of the present invention.

[0013] refer to Figure 2 to Figure 6 . A resistance welding machine for automatic plate rolling, comprising a frame 1, a rotatable welding wheel 2 is arranged in front of the frame 1, and the welding wheel 2 is connected with a front and rear sliding device A and a first lifting device B. A cylindrical lower welding electrode 3 extending along the front of the frame 1 is arranged below the welding wheel 2 . The left and right sides of the lower w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com