Processing assembly line and processing method of clutch part for vehicle

A processing method and clutch technology, applied in the field of auto parts, can solve problems such as unrealized continuous automation, unguaranteed product quality, and unstable production process, so as to improve work efficiency and product strength, make the manufacturing method easy to operate, and process parameters Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A processing method for manufacturing clutch parts for a vehicle using the above-mentioned processing line, comprising the following steps:

[0070] S1: Put the aluminum alloy billet with the mass percentage composition: Si: 0.3%, Mn: 0.1%, Fe: 0.03%, Cr: 0.25%, Er: 0.03%, the balance being Al and unavoidable impurities in the heating device Heating to 450°C;

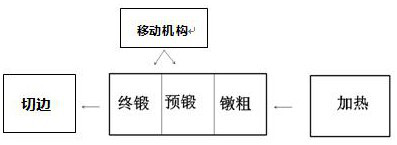

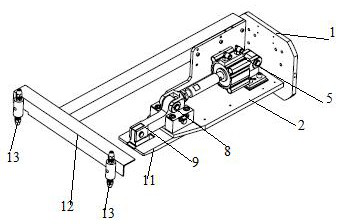

[0071] S2: put the heated billet into the forging device to perform upsetting / pre-forging / final forging in sequence, and the upsetting / pre-forging / final forging is completed through a multi-cavity mold; upsetting / pre-forging / final forging are all in The high-precision die forging hydraulic press is carried out, the pressing speed of the control press is 20mm / s, and the pressure is about 2000 tons; the upsetting and final forging are carried out simultaneously during production, and after the pre-forging is completed, a T-shaped structure mobile device (such as attached figure 2 - attached Figure 5 As shown) w...

Embodiment 2

[0074] A processing method for manufacturing clutch parts for a vehicle using the above-mentioned processing line, comprising the following steps:

[0075] S1: The mass percentage is composed of: Si: 0.5%, Mn: 0.3%, Fe: 0.05%, Cr: 0.28%, Er: 0.04%, and the balance is Al and unavoidable impurities. Place the aluminum alloy billet in the heating device Heating to 470°C;

[0076] S2: Put the heated billet into the forging device for upsetting / pre-forging / final forging in sequence. Upsetting / pre-forging / final forging are all carried out under the high-precision die forging hydraulic press, and the pressurization speed of the control press is 25mm / s , the pressure is about 2000 tons; upsetting and final forging are carried out synchronously during production, and after the pre-forging is completed, a T-shaped structure mobile device (such as attached figure 2 - attached Figure 5 As shown) while the pre-forged product is being transported, the mold is sprayed simultaneously, and...

Embodiment 3

[0079] A processing method for manufacturing clutch parts for a vehicle using the above-mentioned processing line, comprising the following steps:

[0080] S1: The mass percentage is composed of: Si: 0.7%, Mn: 0.5%, Fe: 0.1%, Cr: 0.35%, Er: 0.06%, the balance is Al and unavoidable impurities, and the aluminum alloy blank is placed in the heating device Heating to 490°C;

[0081] S2: Put the heated billet into the forging device for upsetting / pre-forging / final forging in sequence. Upsetting / pre-forging / final forging are all carried out under the high-precision die forging hydraulic press, and the pressurization speed of the control press is 30mm / s , the pressure is about 2000 tons; upsetting and final forging are carried out simultaneously during production. After pre-forging is completed, the T-shaped structure moving mechanism is used to transport the pre-forged products, and at the same time, mold spraying is carried out at the same time. After the final forging, the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com