Cleaning equipment for electronic electromechanical assembly production

A technology for electromechanical components and cleaning equipment, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as workpiece damage, and achieve the effect of precise washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

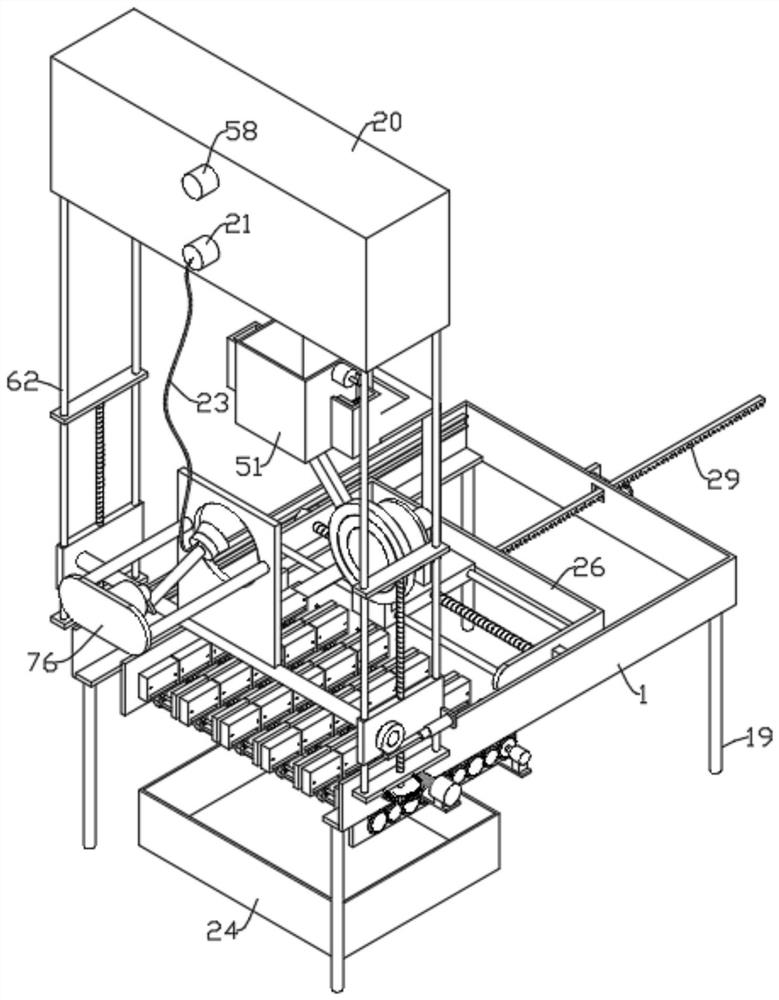

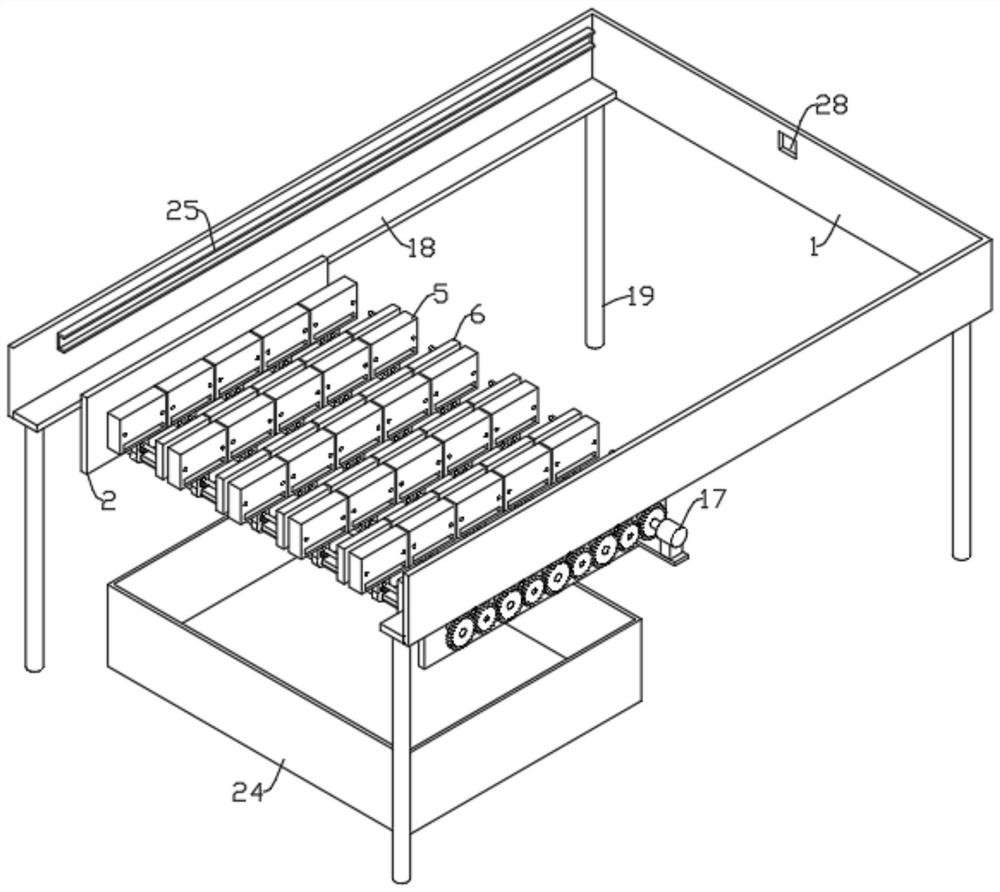

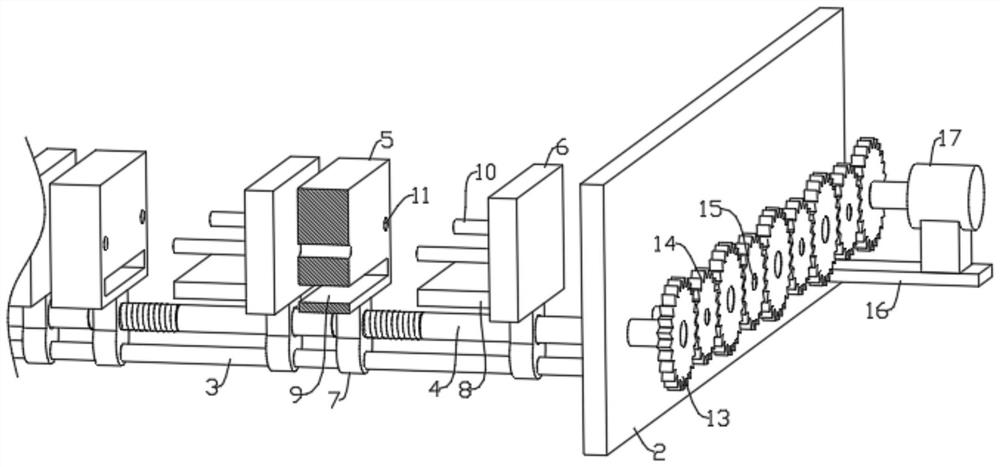

[0027] refer to Figure 1-12 , a cleaning device for the production of electronic electromechanical components, including a U-shaped frame 1, a clamping assembly is arranged in the U-shaped frame 1, the clamping assembly includes two side plates 2 distributed at intervals, and the side plate 2 on one side is provided with There is a driving mechanism, and a plurality of equidistantly distributed clamping mechanisms are arranged between the two side plates 2. The clamping mechanism includes a first guide rod 3, a first screw rod 4 and a plurality of equidistantly distributed clamping units. The two ends of a guide rod 3 are respectively fixedly connected to the side plates 2 on both sides, the thread lines on the first screw mandrel 4 are discontinuously distributed, the thread lines on the first screw mandrel 4 are equidistantly distributed into multiple sections, and the first screw mandrel 4 4 Both ends are rotatably installed on the side plates 2 on both sides, the clamping...

Embodiment 2

[0031] Considering the realization of automatic feeding and flushing, it is not necessary to manually place the workpieces 80 between the movable plate 5 and the fixed plate 6, and at the same time realize the automatic flushing of the nozzles 22, and multiple workpieces 80 can be flushed without manual operation of the nozzles 22.

[0032] refer to Figure 1-12 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that a directional feeding mechanism is provided on the top side of the U-shaped frame 1, and the directional feeding mechanism includes two slide rails 25, and the two slide rails 25 are fixedly installed respectively. On both sides in the U-shaped frame 1, a U-shaped frame 26 is arranged between two slide rails 25, and a slide block 27 is fixedly installed on both sides of the U-shaped frame 26, and the slide block 27 is respectively slidably arranged in the slide rail 25, and the U-shaped frame 26 is fixedly mounted on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com