Reaction equipment with product separation function

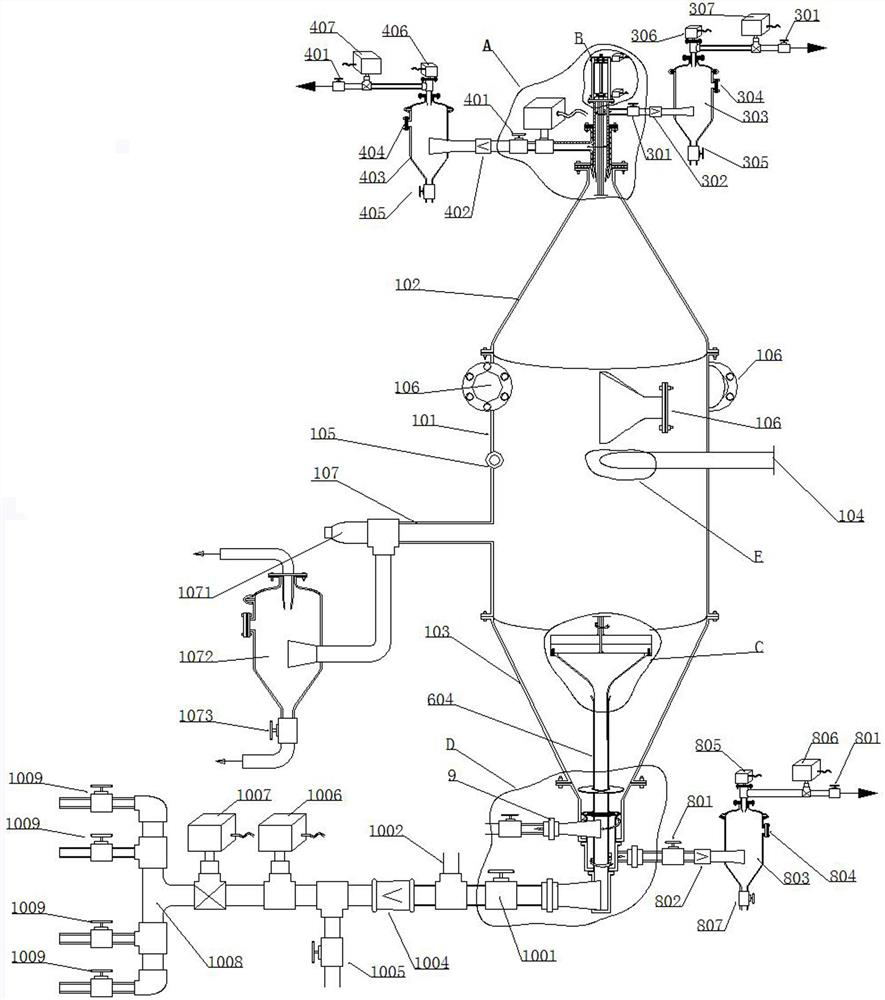

A technology of reaction equipment and products, applied in the field of reaction equipment with product separation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

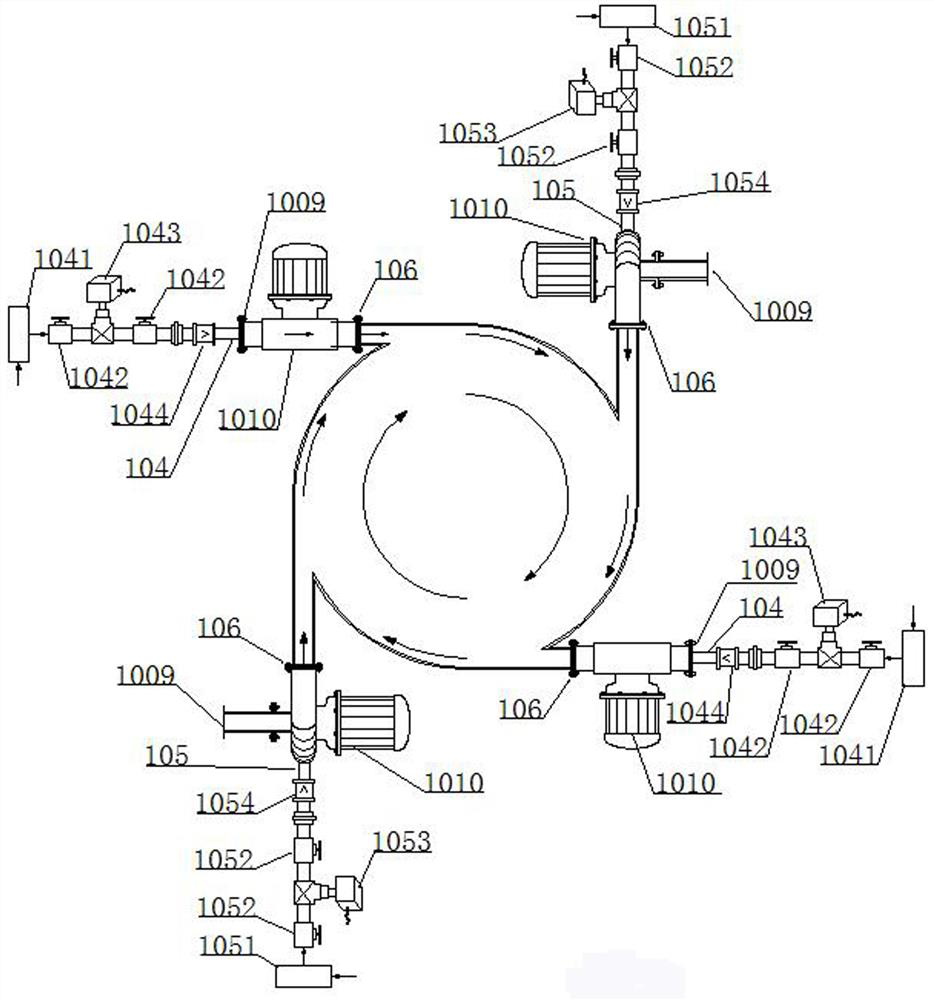

[0105] Example: The reaction feedstock is a gas and a liquid

[0106] Step 1: Turn on the valve on the gas reactant feed tube 104 and the liquid reactant feed tube 105, turn on the shunt pipe switch valve 1009, the slag fluid outlet switch valve 901 (near the sediment tank side) and the reflow switch valve 1003, close The switch valve I301, switching valve II401, switch valve III 81, shutdown cycle reaction fluid outlet switch valve 1001, and various two-point can bottom switch valve 1001, and the switch valve 305, 405, 807 of each of the two-point tank bottom switch valve 1001, and the switch valve 305, 405, 807, close up. The cleaning switch valve 909 of 902 is turned off the switching valve I301, the switching valve II401, the switching valve III 801, and then opens the total power switch on the control cabinet 11.

[0107] Step 2: Press the setting button of the control cabinet 11 on the control cabinet 11, set the working pressure of the anti-tank, then press the button to br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com