Licorice-flavored fermented milk and preparation method thereof

A technology for fermented milk and flavor, applied in the direction of bacteria and lactobacilli used in dairy products and food preparation, can solve the problems of poor stability and loss of yogurt, ensure stability, enrich taste, and solve the problem of yogurt stability. worsening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

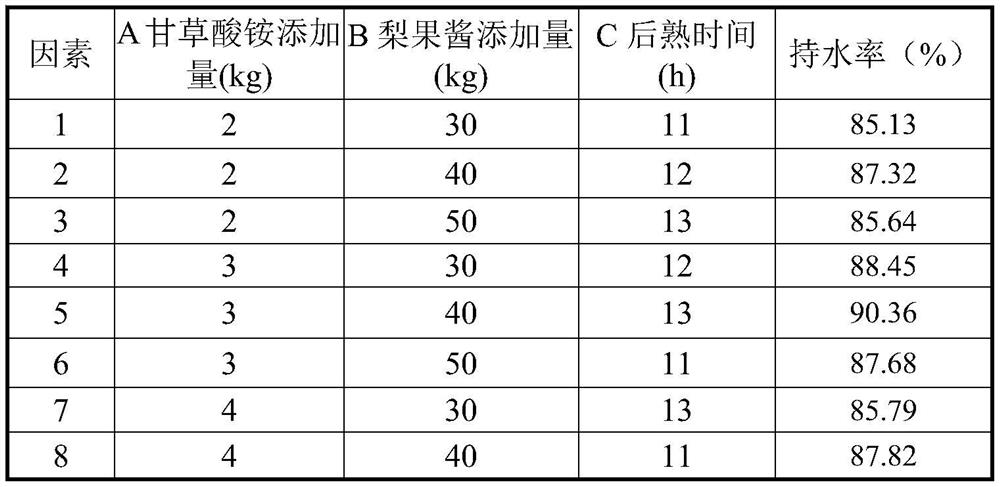

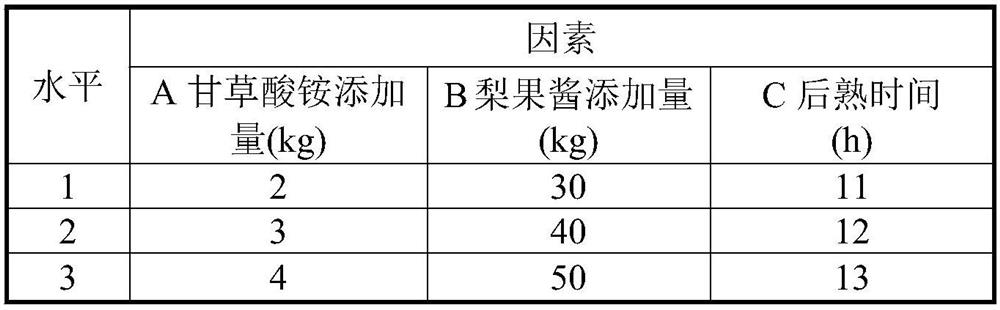

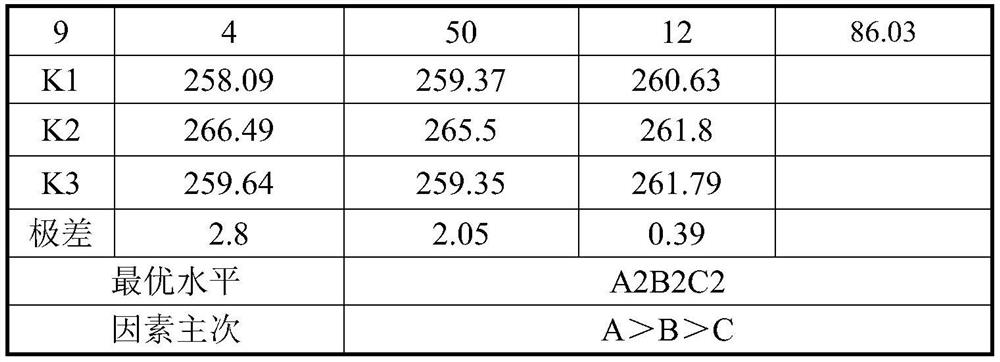

Image

Examples

Embodiment 1

[0024] Embodiment 1: Licorice flavor fermented milk

[0025] The licorice-flavored fermented milk comprises 800-1000 parts of raw milk, 50-80 parts of white sugar, 20-60 parts of pear jam and 2-4 parts of ammonium glycyrrhizinate in parts by weight.

Embodiment 2

[0026] Embodiment 2: Licorice flavor fermented milk

[0027] A licorice-flavored fermented milk, comprising 900kg of raw milk, 60kg of white sugar, 40kg of pear jam, and 3kg of ammonium glycyrrhizinate.

Embodiment 3

[0028] Embodiment 3: Licorice flavor fermented milk

[0029] A licorice-flavored fermented milk, comprising 800 kg of raw milk, 50 kg of white sugar, 20 kg of pear jam, and 2 kg of ammonium glycyrrhizinate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com