Electrothermal magnetic isolation multiphase fault-tolerant motor

A multi-phase fault-tolerant motor and magnetic isolation technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuits, electromechanical devices, etc., can solve the problems of small motor torque density, complex manufacturing process, and no consideration , to achieve the effect of increasing torque density, increasing air gap magnetic density, and meeting high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

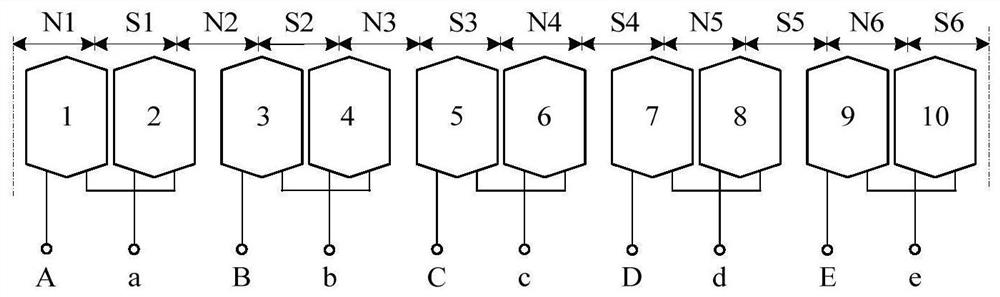

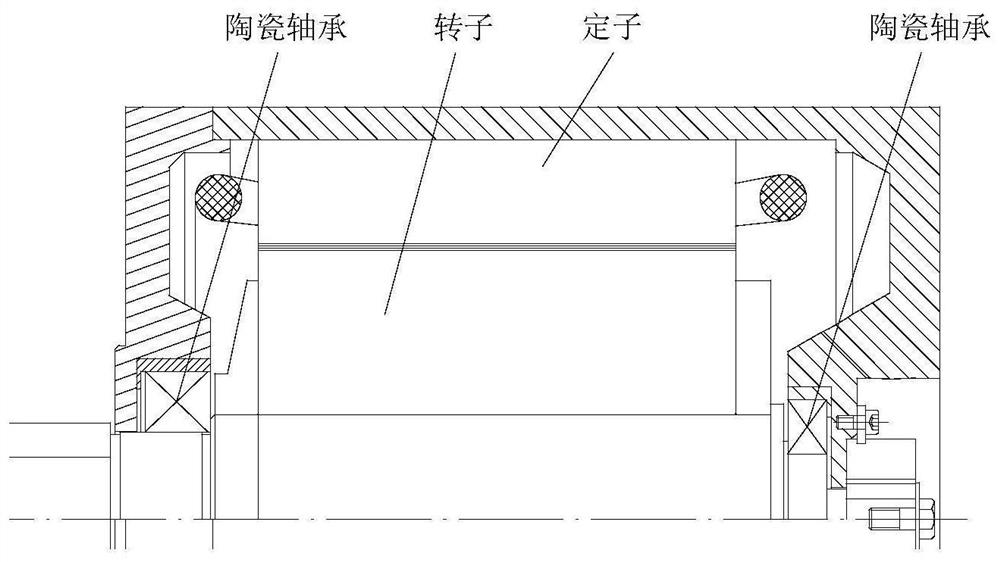

[0026] Such as figure 1 , 5 As shown, the multi-phase fault-tolerant motor of electrothermal and magnetic isolation proposed by the present invention is a five-phase permanent magnet synchronous motor, including a stator, a rotor, a housing, an end cover, a rotary transformer and a bearing;

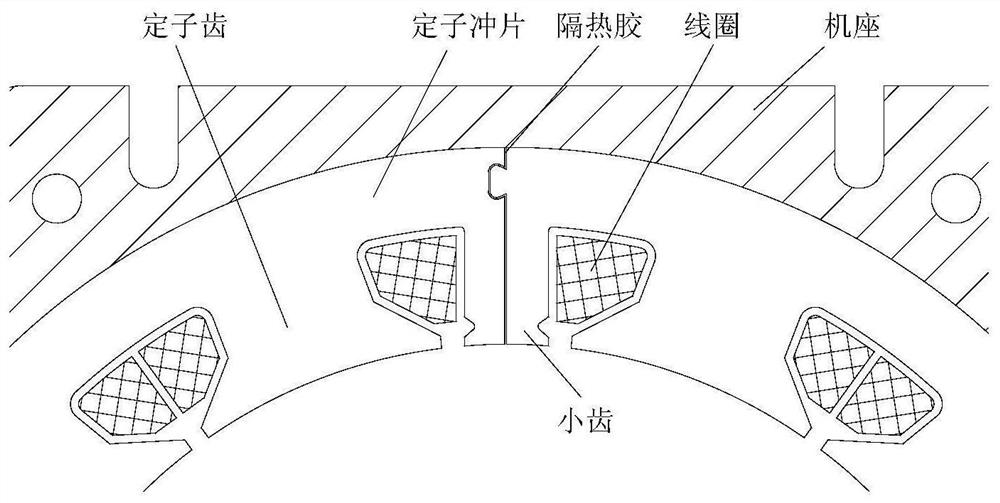

[0027] refer to figure 1 , 2 According to the concept of modular design, the motor stator of the present invention includes a motor casing and a stator core, and the stator core includes five modules in total. figure 1 For one of the modules, a phase winding is wound on each module. Each module includes two large teeth and two small teeth. The winding coil is wound on the two large teeth, and the two small teeth are used for magnetic isolation. The outer side of each small tooth is coated with heat-insulating glue, and after the stator module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com