110 kilovolt double-circuit triangularly-arranged cable terminal pole

A technology of cable terminal and triangular arrangement, which is applied in the direction of cable installation, cable suspension device, cable space arrangement/configuration, etc., and can solve the problem that the distance between 110 kV wires and the ground is not high, the phase transformation of wires is not flexible enough, and cannot be mixed. Problems such as straight-line tower overlap and other problems can be solved to reduce personnel electric shock casualties, increase the height of the call, and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments, and it should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention.

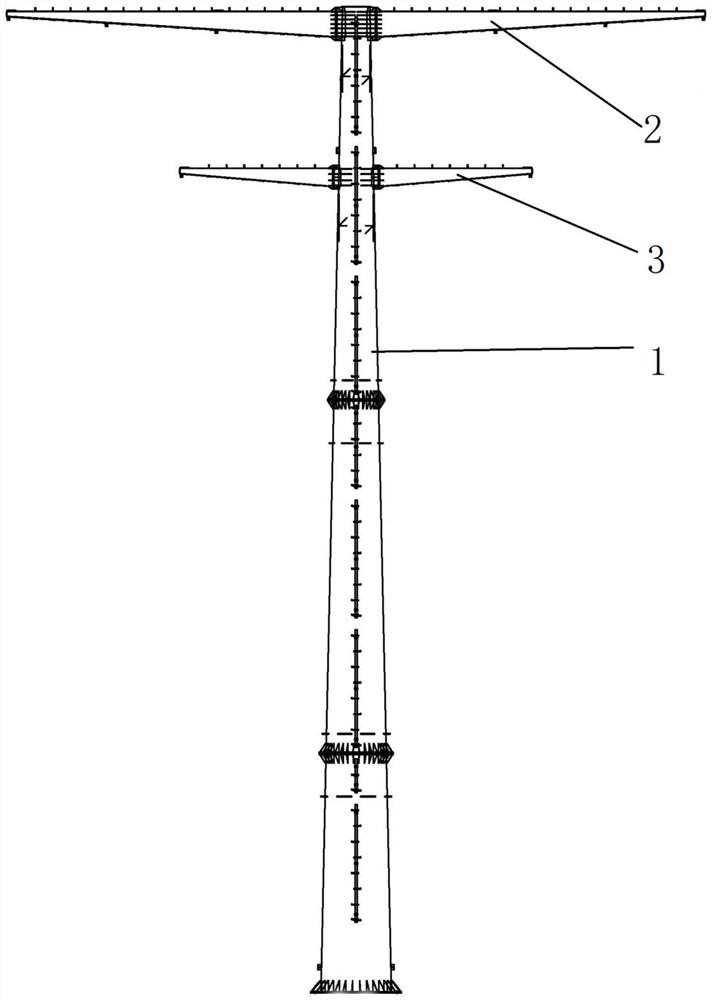

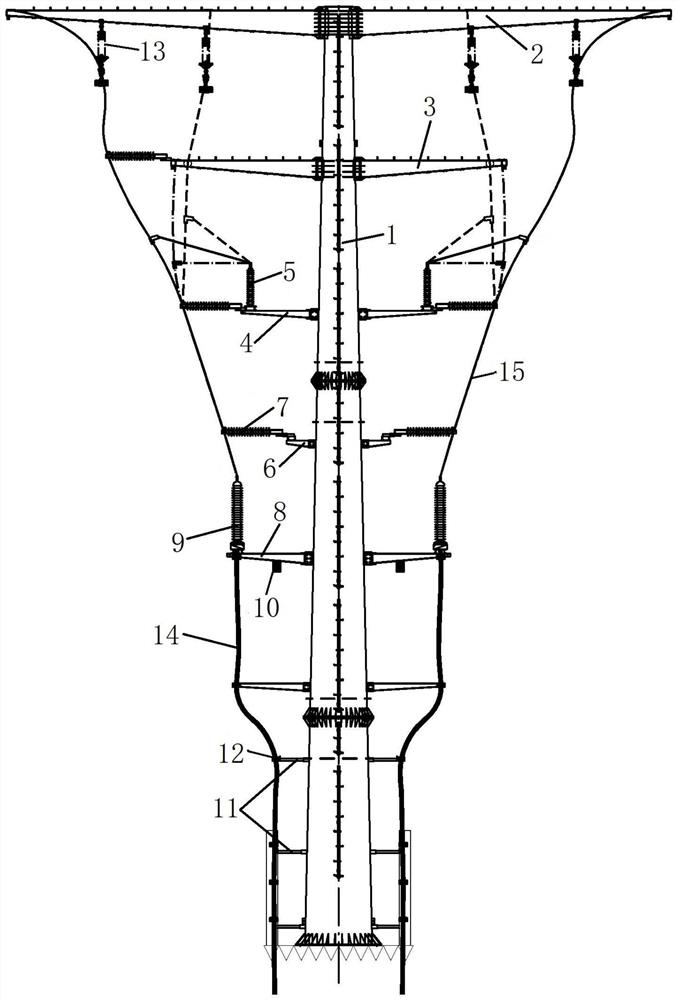

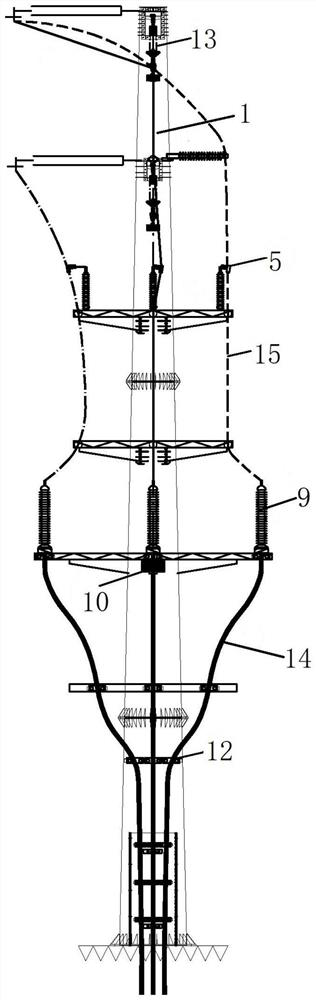

[0020] A 110 kV double circuit triangular cable terminal rod, such as Figure 1~3 As mentioned above, it includes the main pole 1, the first cross arm 2, the second cross arm 3, the lightning arrester platform, the composite insulator cross arm 6, the composite cross arm insulator 7, the cable terminal platform, the cable lead bracket 11, the cable clamp 12, the jumper Line insulator string 13.

[0021] The main pole 1 is a segmented splicing structure, which is divided into multiple sections along its axial direction and fixed in sequence. The main pole 1 is vertically arranged, and its ground height is about 25.1m. The first cross arm 2 is on the opposite sides of the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com