A Control Method of High Power Hydraulic Retarder

A hydraulic retarder and control method technology, applied in the direction of liquid resistance brakes, transmission control, brakes, etc., can solve the problems of car crashes, single hydraulic retarders, and shortened service life of engines, and achieve guaranteed The effects of safety, loss recovery, and damage avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

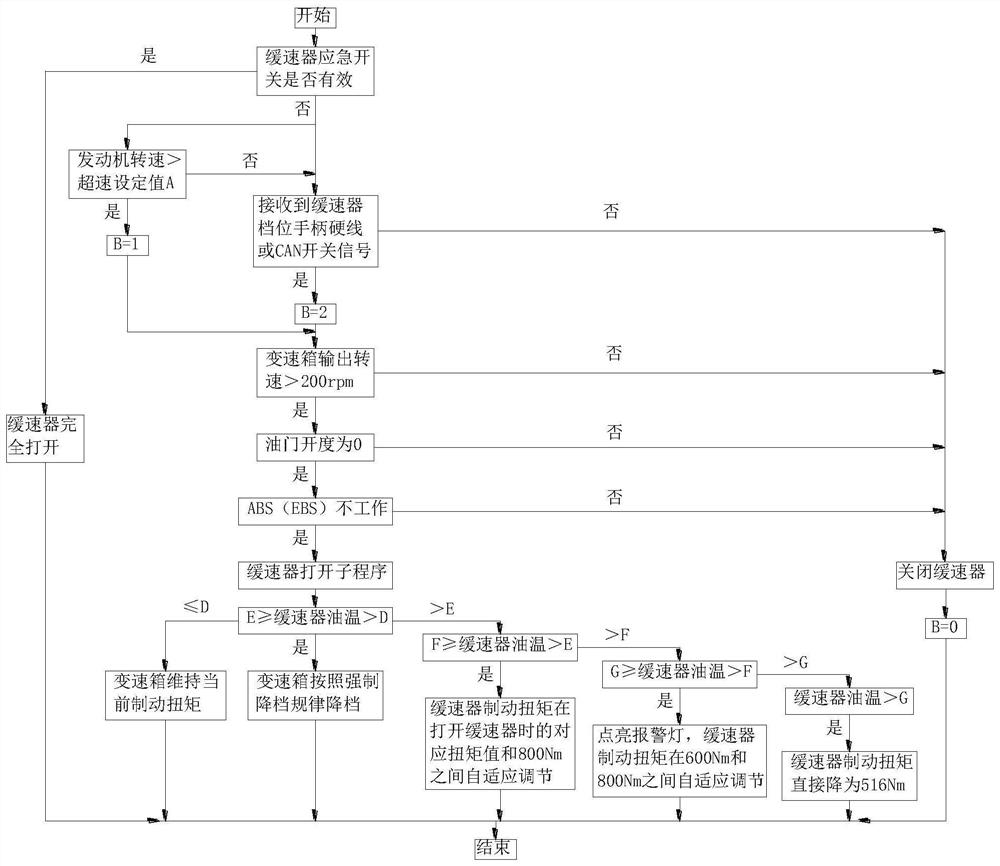

[0038] Such as Figure 1 to Figure 3 As shown, a control method of a high-power hydraulic retarder according to the present invention includes the following steps:

[0039] (1) The controller judges whether the emergency switch signal of the retarder is valid. If it is valid, the retarder is fully opened and ends, and enters the next cycle. If it is invalid, it directly enters the next step;

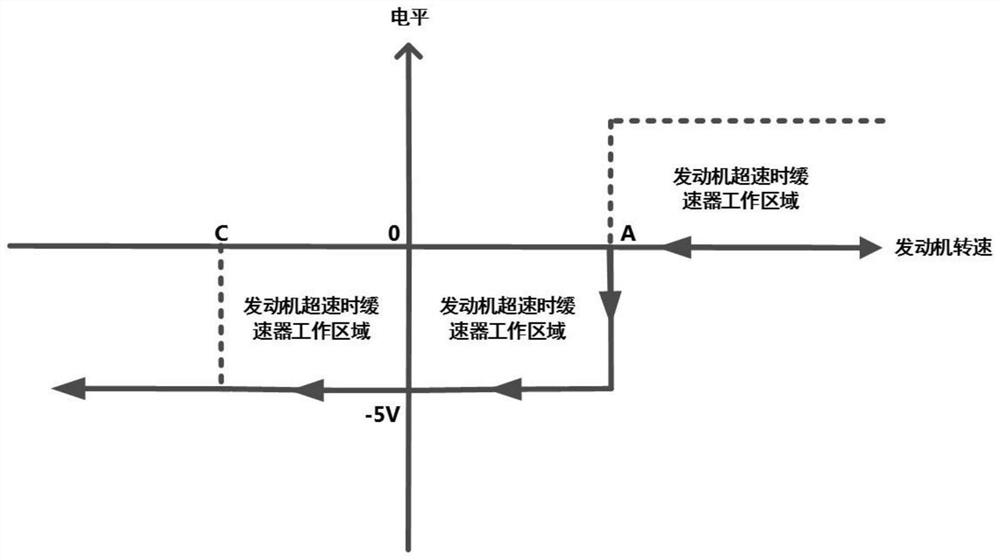

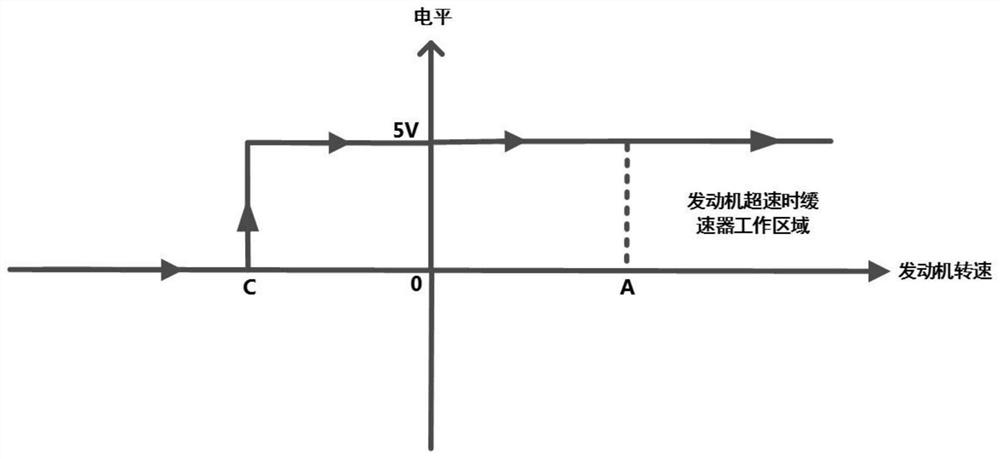

[0040] (2) The controller decides whether to open the retarder according to the engine speed. If the retarder is opened, it will directly enter the next step. Otherwise, it will try to open the retarder according to whether it receives the hard line of the retarder gear handle or the CAN switch signal. , to decide whether to open the retarder, if one of the signals is received to try to open the retarder, then go directly to the next step, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com