Closed impeller and gas compressor

A closed impeller and compressor technology, applied in the field of compressors, can solve the problems of increased axial size of compressors, increased processing and assembly errors, high processing and assembly difficulties, etc., to achieve improved flow field, increased rigidity, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

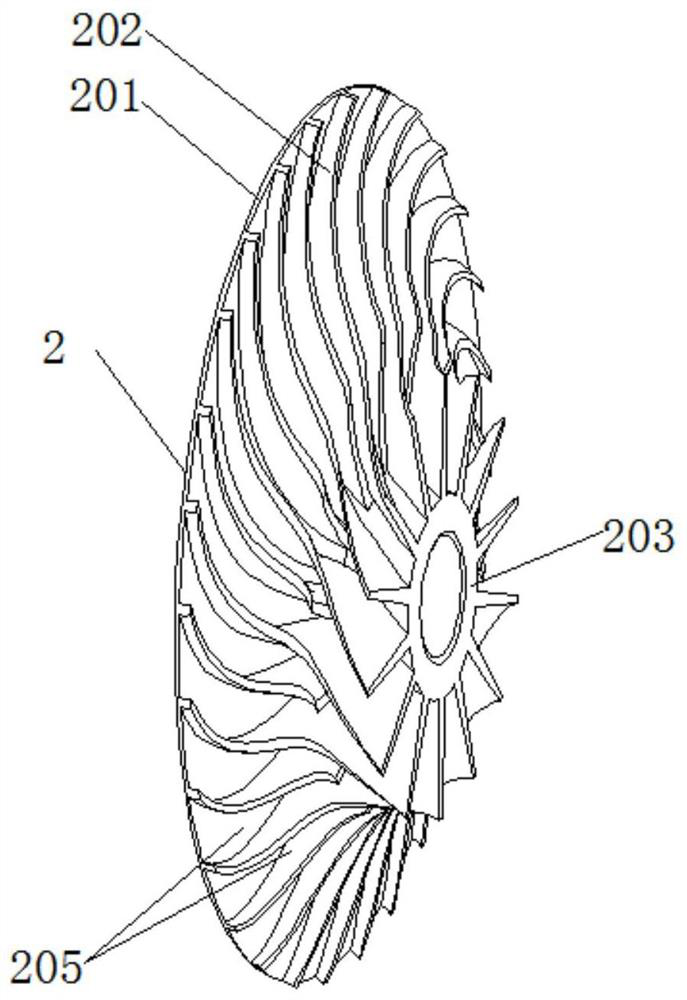

[0045] A closed impeller, including a rear cover 201, blades 202, a casing 203 and a front cover 204, such as Figure 1~5As shown, wherein, the rear cover 201 is arranged at the tail end of the sleeve body 203, and the center of the rear cover 201 and the sleeve body 203 is provided with an integrated through hole for sheathing and fixing on the rotating shaft 1; the blade 202 is arranged around the sleeve body 203 and faces Rotating in the same direction, one end of the blade 202 is connected to the outer wall of the sleeve body 203, and the other end is connected to the end face of the rear cover 201; A curved surface with a smooth transition along the outline of the ridge line of the blade 202, the back air surface is provided with grooves that match the ends of the blades 202, and the ends of the blades 202 corresponding to each groove are embedded in the grooves for tight fit connection; the blade 202, the rear cover 201 A flow channel 205 is formed between the front cove...

Embodiment 2

[0062] A compressor includes a rotating shaft 1, on which an impeller 2 and a motor 4 are sheathed; wherein, the structure of the impeller includes a rear cover 201, blades 202, a casing 203 and a front cover 204, such as Figure 1~5 As shown, wherein, the rear cover 201 is arranged at the tail end of the sleeve body 203, and the center of the rear cover 201 and the sleeve body 203 is provided with an integrated through hole for sheathing and fixing on the rotating shaft 1; the blade 202 is arranged around the sleeve body 203 and faces Rotating in the same direction, one end of the blade 202 is connected to the outer wall of the sleeve body 203, and the other end is connected to the end face of the rear cover 201; A curved surface with a smooth transition along the outline of the ridge line of the blade 202, the back air surface is provided with grooves that match the ends of the blades 202, and the ends of the blades 202 corresponding to each groove are embedded in the grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com