Rotary oiling device and compressor

A technology for compressors and oil pipes, which is applied to components of pumping devices for elastic fluids, rotary piston type/swing piston type pump components, mechanical equipment, etc. Compressor cost and other issues, to achieve the effect of improving generalization rate, reducing manufacturing cost, and reducing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order for those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

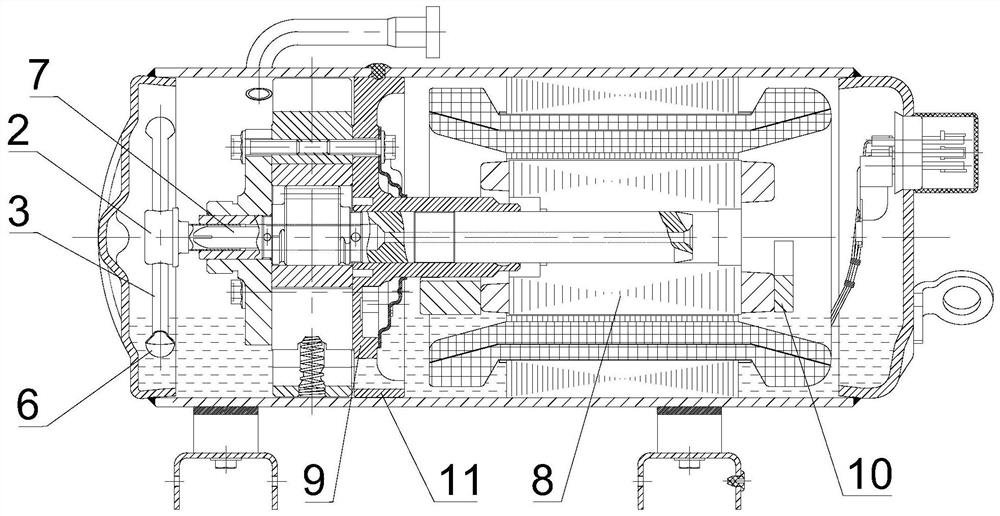

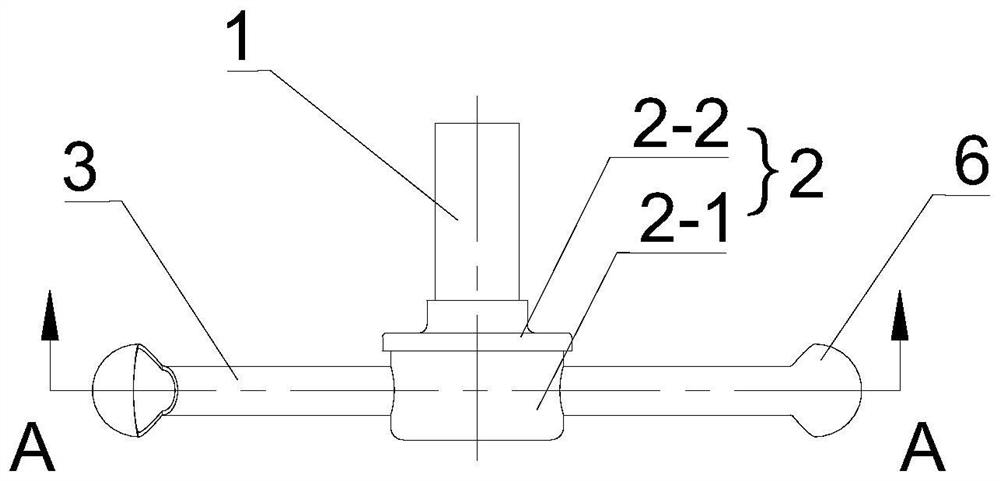

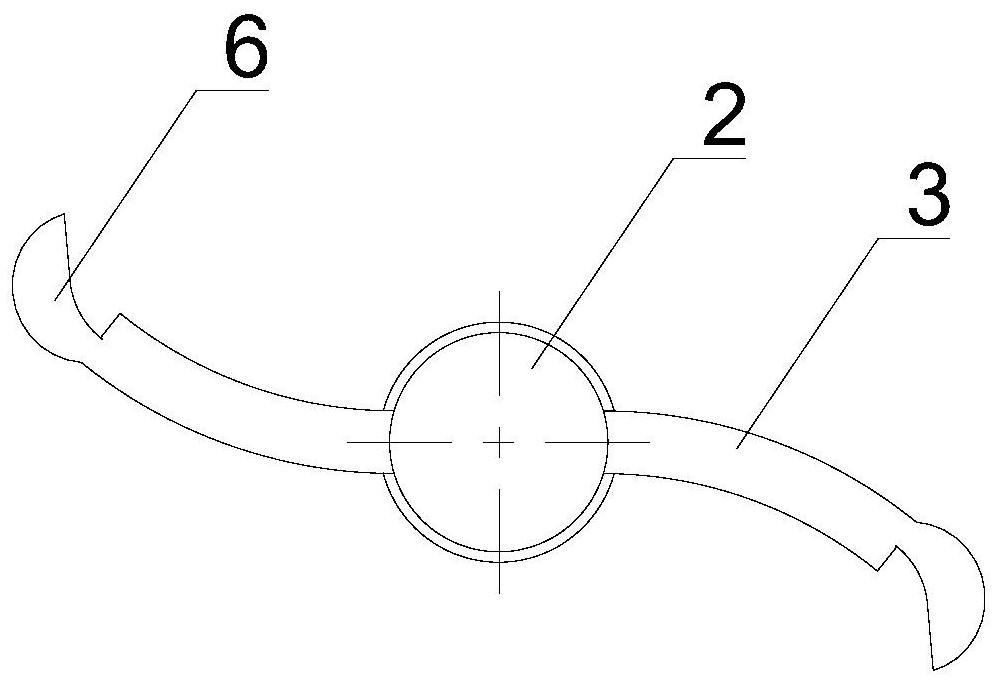

[0034] see Figure 1-6 , the compressor in this embodiment includes a rotary oiling device, the rotary oiling device includes a transmission oil pipe 1, an oil cover 2 and an oil supply pipe 3, one end of the intermediate transmission oil pipe 1 is fixedly connected to the crankshaft, and the other One end is connected to the inner cavity of the upper oil cover 2; the intermediate transition oil pipe 4 is fixed inside the upper oil cover 2, and the inner cavity of the intermediate transition oil pipe 4 is provided with a sealing ball 5, and the intermediate transition oil pipe 4 is provided with multiple two oil passage holes 4-1; the upper oil pipe 3 is provided with two, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com