Cutting-off equipment for cutting off length-adjustable polyester staple fiber

A technology of polyester staple fiber and cutting equipment, which is applied in the direction of forming non-bundle shape, etc., can solve the problems of no protective mechanism, no cutting length, easy accidental injury of staff by cutting knife, etc., so as to ensure safety and facilitate maintenance operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

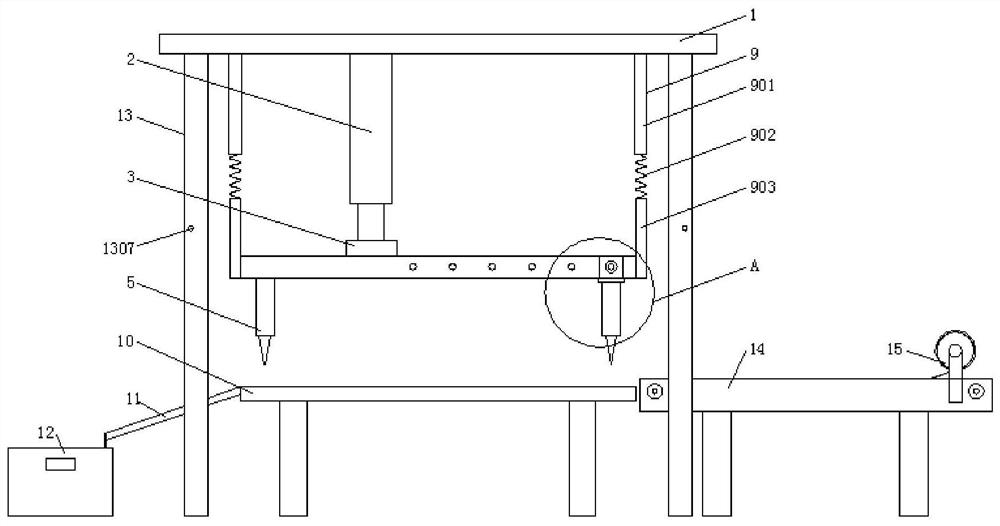

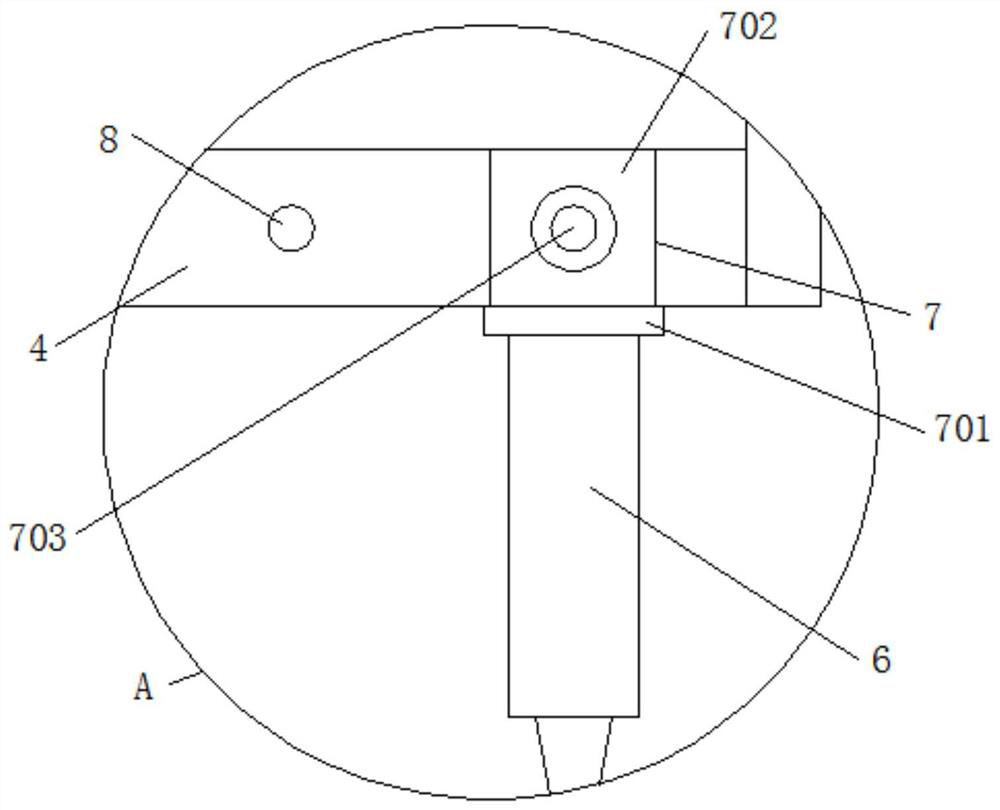

[0027] like figure 1 and image 3 As shown, the present invention provides a polyester staple fiber processing cutting device with adjustable cutting length, including: supporting top plate 1, cylinder 2, connecting block 3, connecting plate 4, adjusting mechanism 7, stabilizing mechanism 9 and protective mechanism 13, The stabilizing mechanism 9 is installed between the support top plate 1 and the connecting plate 4, one end of the connecting plate 4 is provided with a threaded hole 8, the bottom end of the connecting plate 4 is equipped with a first cutting knife 5, the bottom of the adjusting mechanism 7 is The second cutting knife 6 is fixedly installed, and the cutting table 10 is fixedly installed below the second cutting knife 6; the adjustment mechanism 7 includes a fixed bottom plate 701, a fixed side plate 702 and a fastening bolt 703; wherein, the fixed side plate 702 It is fixedly installed at both ends of the top surface of the fixed bottom plate 701 , and the fa...

Embodiment 2

[0032] like figure 1 As shown, the present embodiment provides a cutting-off equipment for polyester staple fiber processing with adjustable cutting length. The difference from Embodiment 1 is that the stabilizing mechanism 9 is installed between the supporting top plate 1 and the connecting plate 4, and the stabilizing mechanism 9 9 includes a first suspension rod 901 , a connecting spring 902 and a second suspension rod 903 .

[0033] Preferably, in one of the preferred technical solutions of this embodiment, a connection spring 902 is fixedly installed at one end of the first suspension rod 901 , and a second suspension rod 903 is fixedly installed at the other end of the connection spring 902 .

[0034] In practical applications, the first suspender 901 is connected to the supporting top plate 1, one end of the second suspender 903 is connected to the connecting plate 4, and the first suspender 901 and the second suspender 903 are connected by a connecting spring 902. The...

Embodiment 3

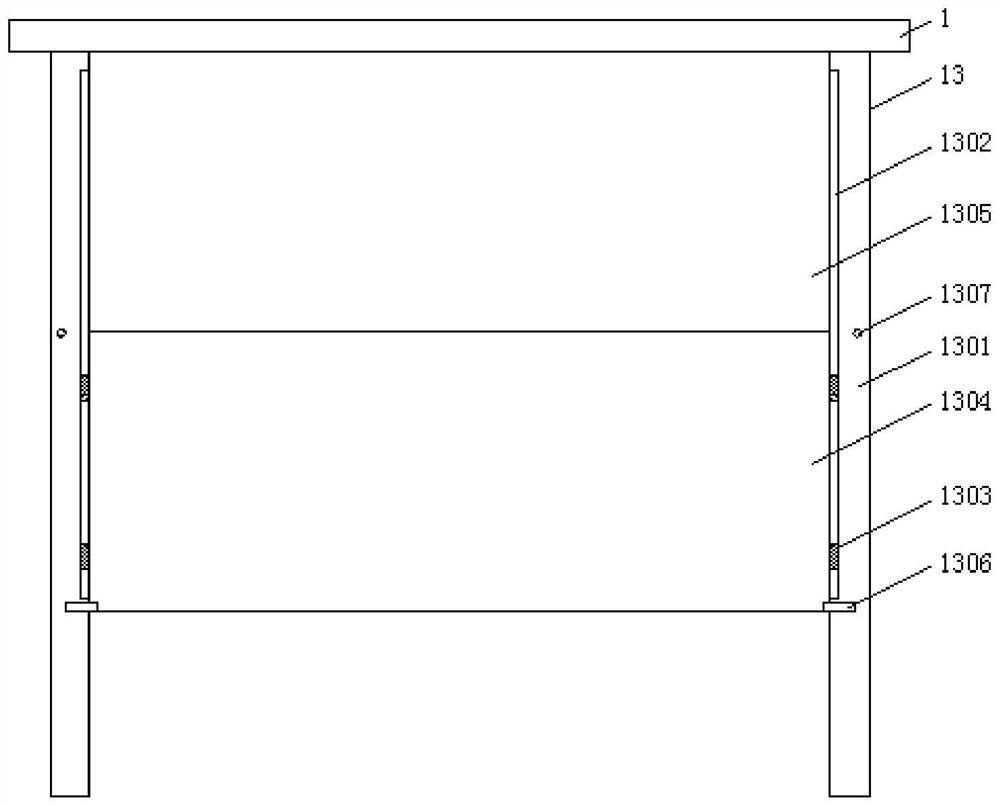

[0037] like figure 1 and figure 2 As shown, this embodiment provides a polyester staple fiber processing cutting device with adjustable cutting length. The difference from Embodiment 2 is that the protective mechanism 13 is installed on both sides of the supporting top plate 1, and the protective mechanism 13 includes The support column 1301 , the chute 1302 , the slider 1303 , the first transparent protective plate 1304 , the second transparent protective plate 1305 , the clamping bar 1306 and the limiting protrusion 1307 .

[0038] Preferably, in one of the preferred technical solutions of this embodiment, the first transparent protective plate 1304 is slidably installed in the sliding groove 1302 through the slider 1303, and the second transparent protective plate 1305 is fixedly installed on two sets of support columns 1301 , the first transparent protective plate 1304 is fixed on the outside of the second transparent protective plate 1305 through clamping strips 1306 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com