Anti-counterfeiting modal fiber, preparation method and anti-counterfeiting method

A technology of modal fiber and cellulose, which is applied in the field of preparation and anti-counterfeiting modal fiber, can solve problems such as the use of amino acid metal chelate anti-counterfeiting materials that have not been disclosed in the technology, and achieve effective encryption and traceability, high anti-counterfeiting strength, and timeliness long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

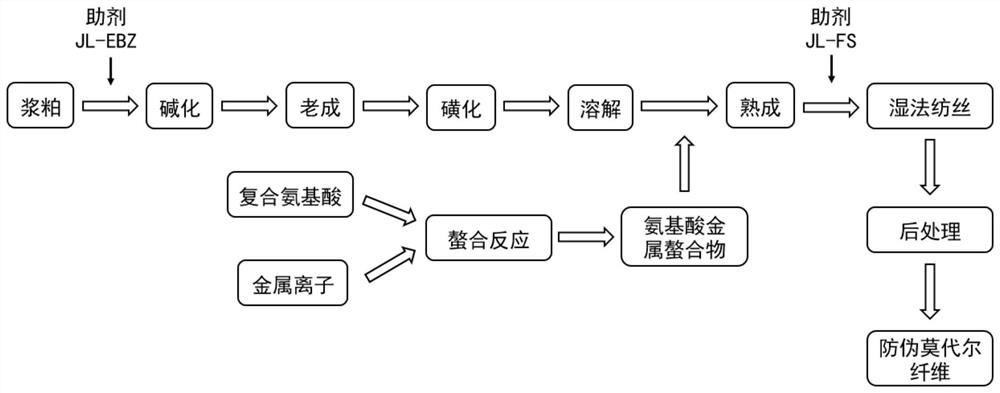

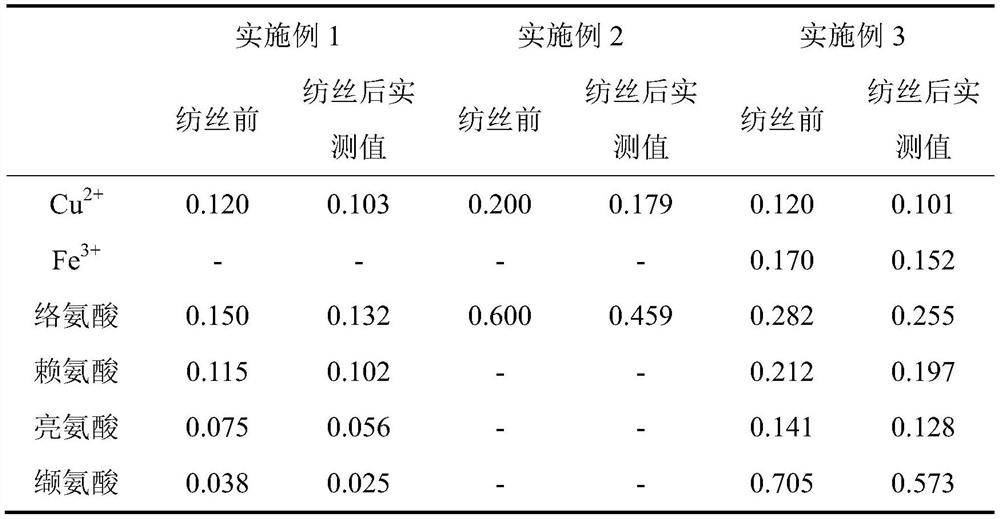

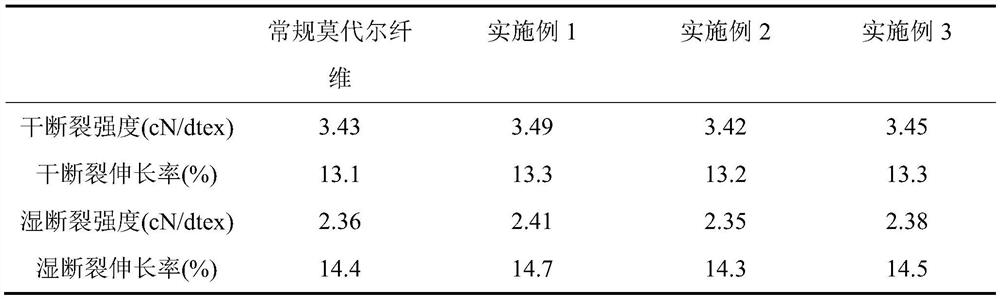

[0047] This embodiment provides a kind of anti-counterfeiting modal fiber and its preparation method, its technical process is as follows figure 1 As shown, the specific steps are as follows:

[0048] (1) Firstly, the auxiliary agent JL-EBZ is added to the pulp stock solution, and JL-EBZ accounts for 0.6% of the mass fraction of the pulp stock solution. Then carry out alkalization treatment with sodium hydroxide, and the pulp stock solution after alkalization treatment is aged in the aging equipment, and the pulp stock solution processed by aging is processed by CS 2 Carrying out sulfonation treatment, adding the sulfonated cellulose sulfonate into sodium hydroxide solution for dissolution treatment to obtain spinning viscose. Among them, the specific conditions of alkalization treatment, aging treatment and sulfonation treatment are as follows:

[0049] The concentration of sodium hydroxide in the alkalization treatment is 18g / L, and it is treated at 15°C for 3 hours, and t...

Embodiment 2

[0054] This embodiment provides an anti-counterfeiting modal fiber and a preparation method thereof, the specific steps are as follows:

[0055] (1) Perform the same steps as step (1) in Example 1 to prepare spun viscose.

[0056] (2) The amino acid metal chelate is a chelate of tyrosine and copper sulfate pentahydrate. Mix tyrosine and copper sulfate pentahydrate in a molar ratio of 3:1. The pH value is 10 and the temperature is 60°C. The chelation reaction was carried out under certain conditions, and the reaction time was 30 minutes. The mixed solution obtained after the reaction is centrifuged, and the supernatant is taken to obtain an amino acid chelated copper solution.

[0057] (3) the amino acid chelated copper solution obtained in step (2) is added in the spinning viscose, and the amino acid chelated copper accounts for 0.8% of the mass fraction of the spinning viscose. The remaining steps are the same as step (3) in Embodiment 1.

[0058] (4) Perform the same step...

Embodiment 3

[0060] This embodiment provides an anti-counterfeiting modal fiber and a preparation method thereof, the specific steps are as follows:

[0061] (1) Perform the same steps as step (1) in Example 1 to prepare spun viscose.

[0062] (2) Prepare two kinds of amino acid metal chelates, mix the compound amino acid and ferric chloride in a molar ratio of 2:1, and carry out the chelation reaction at a pH value of 6 and a temperature of 25°C, and the reaction time is 30 minutes , the mixed solution obtained after the reaction is centrifuged, and the supernatant is taken to obtain an amino acid chelated iron solution; the compound amino acid is mixed with copper sulfate pentahydrate in a molar ratio of 3:1, and the pH value is 11, and the temperature is 60 Under the condition of ℃, carry out chelation reaction, the reaction time is 30 minutes, wherein compound amino acid is tyrosine, lysine, leucine, valine, and the molar ratio of four in order is 4:3:2:1, will The mixed solution obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com