Method for synthesizing MCM-49 type zeolite molecular sieve under condition of no organic template agent

A technology of MCM-49 and zeolite molecular sieves, which is applied in the field of synthesizing MCM-49 zeolite molecular sieves, can solve problems such as pollution and increase the production cost of zeolite catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] As a preferred embodiment, the synthesis method of the seed crystal comprises:

[0044] S201a, form a silica-alumina gel under stirring and mixing at room temperature through an alkali metal oxide source, an alumina source, and a silica source, so that the silica-alumina gel has the following molar ratio relationship: Na 2 O / SiO 2 =0.15~0.25, SiO 2 / Al 2 o 3 =25~35,H 2 O / SiO 2 =25~50, HMI / SiO 2 =0.5~0.6;

[0045] S202a. Aging and crystallizing the above-mentioned silica-alumina gel to obtain a seed crystal product, cooling the seed crystal product to room temperature, washing to neutrality, drying and calcining to obtain MCM-49 Zeolite molecular sieve seeds.

[0046] As a preferred embodiment, the synthesis method of the seed crystal comprises:

[0047] S201b, form a silica-alumina gel under stirring and mixing at room temperature through an alkali metal oxide source, an alumina source, and a silica source, so that the silica-alumina gel has the following molar...

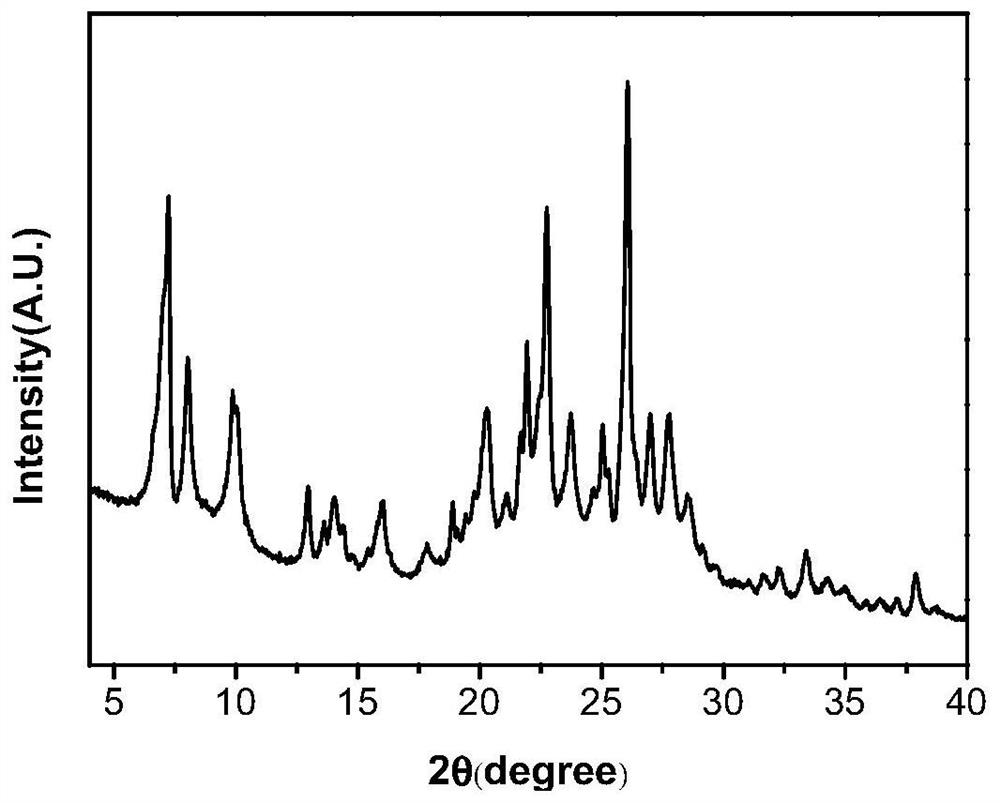

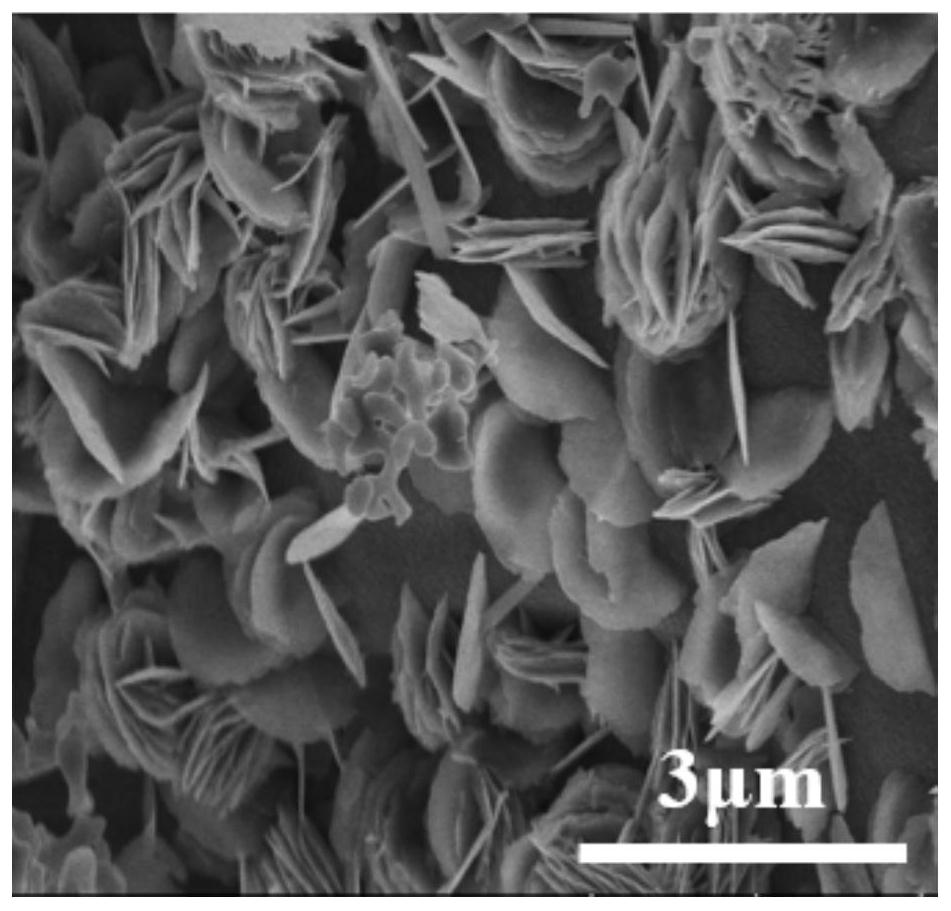

Embodiment 1

[0057] A method for synthesizing an MCM-49 type zeolite molecular sieve without an organic template, comprising the steps of:

[0058] Dissolve 0.3284g of sodium metaaluminate and 0.1344g of sodium hydroxide in 21.6g of water. After dissolving, add 6g of silica sol to the above solution, and form a silica-alumina gel after stirring for about 1 hour; put the above gel into a Aged for 12 hours at 50°C in a stainless steel reaction kettle lined with polytetrafluoroethylene. Add 0.15g SiO 2 / Al 2 o 3 =25-35 MCM-49 molecular sieve seed crystals were added to the above-mentioned silica-alumina gel, and the stirring was continued at room temperature for 10-15 minutes. Crystallize at 150°C for 3 days; after cooling, filter at room temperature to obtain the crystallized product; naturally cool the crystallized product to room temperature, and then wash the crystallized product in a centrifuge with a centrifugal speed of 8000-12000r / min for 1- 3 times, then dried, and finally calcin...

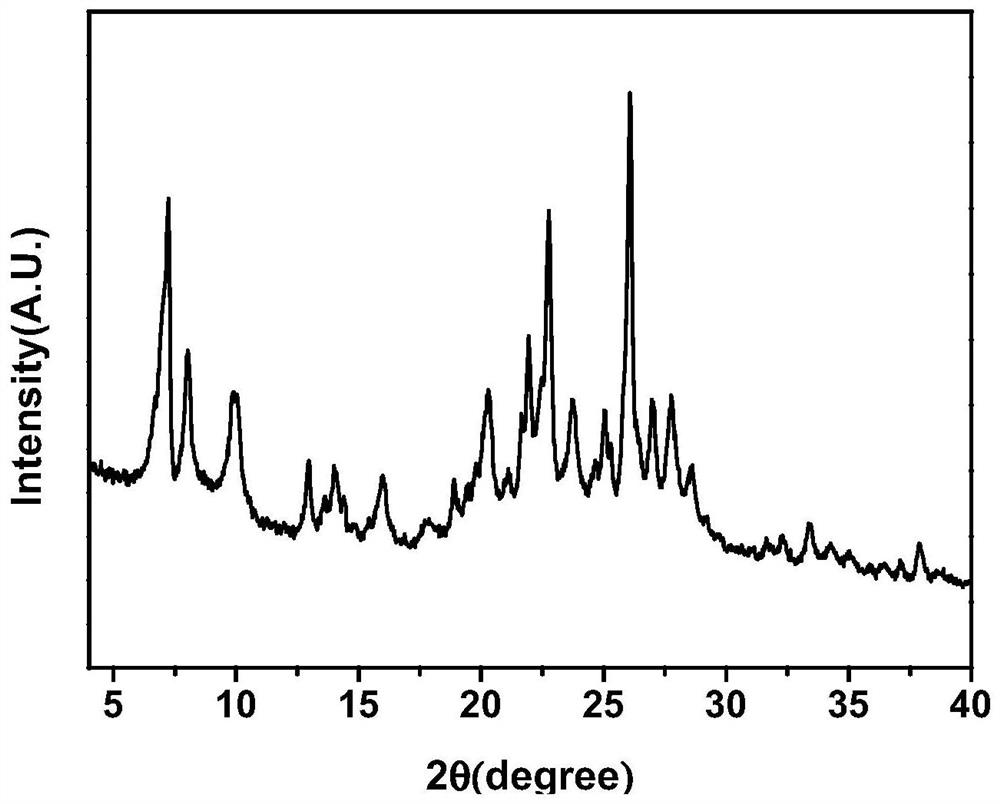

Embodiment 2

[0065] A method for synthesizing an MCM-49 type zeolite molecular sieve without an organic template, comprising the steps of:

[0066] Dissolve 0.2463g of sodium metaaluminate and 0.0344g of sodium hydroxide in 5.9417g of water. After dissolving, add 6.9519g of water glass into the above solution, stir for about 1 hour to form a silica-alumina gel, and put the above gel into Aged for 12 hours at 80°C in a stainless steel reaction kettle lined with polytetrafluoroethylene. Add 0.15g SiO 2 / Al 2 o 3 =25-35 MCM-49 molecular sieve seed crystals were added to the above-mentioned silica-alumina gel, and the stirring was continued at room temperature for 10-15 minutes. Crystallize at 150°C for 5 days; after cooling, filter at room temperature to obtain the crystallized product; naturally cool the crystallized product to room temperature, and then wash the crystallized product in a centrifuge with a centrifugal speed of 8000-12000r / min for 1- 3 times, then dried, and finally calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com