Cutting process of synthetic leather for shoes

A synthetic leather and cutting technology, applied in the direction of footwear, application, thin material processing, etc., can solve the problems of inconvenient centralized management, messy stacking of leftover materials, affecting the progress of shoe production, etc., and achieve the effect of centralized management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

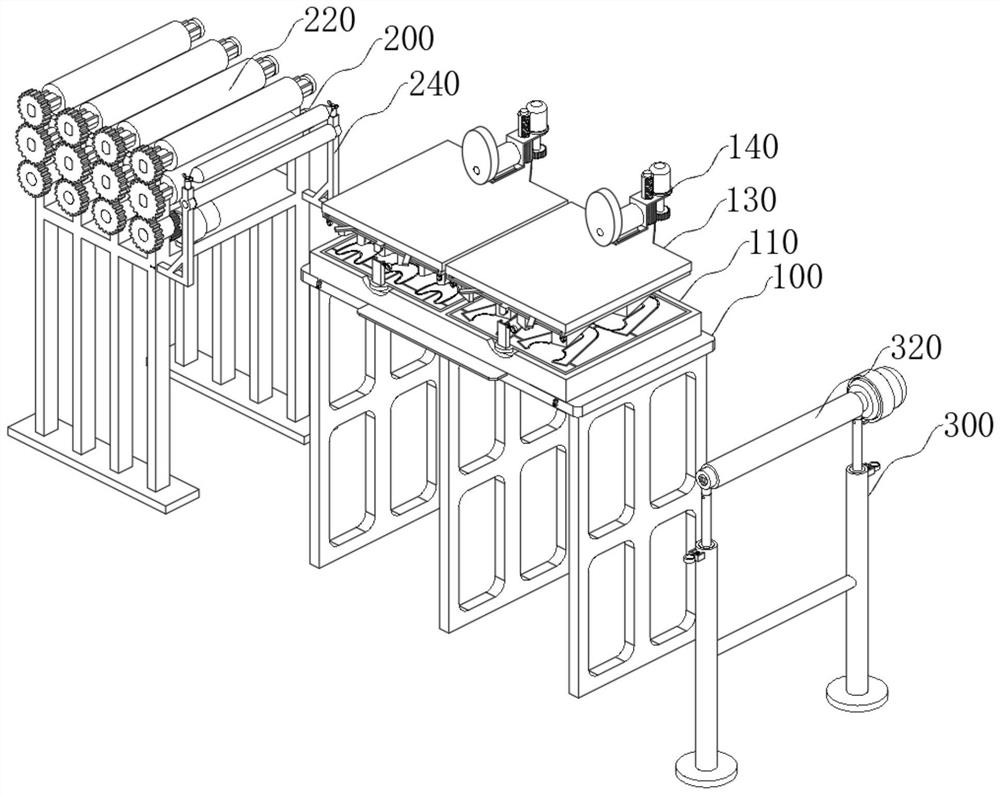

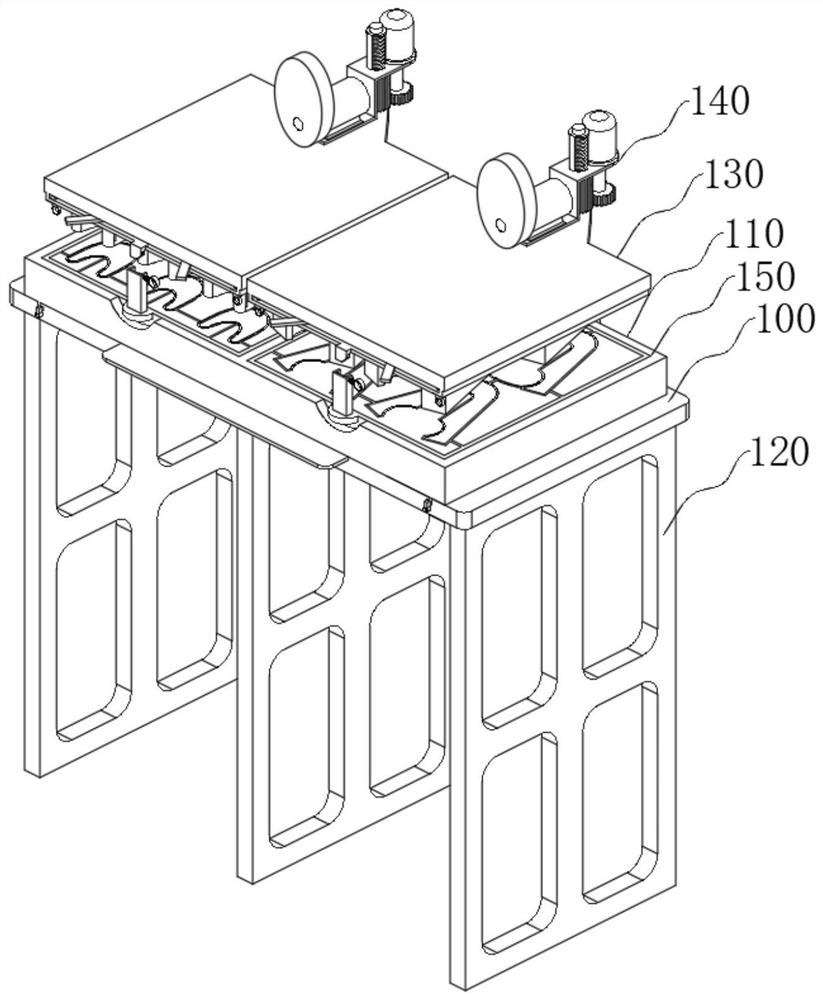

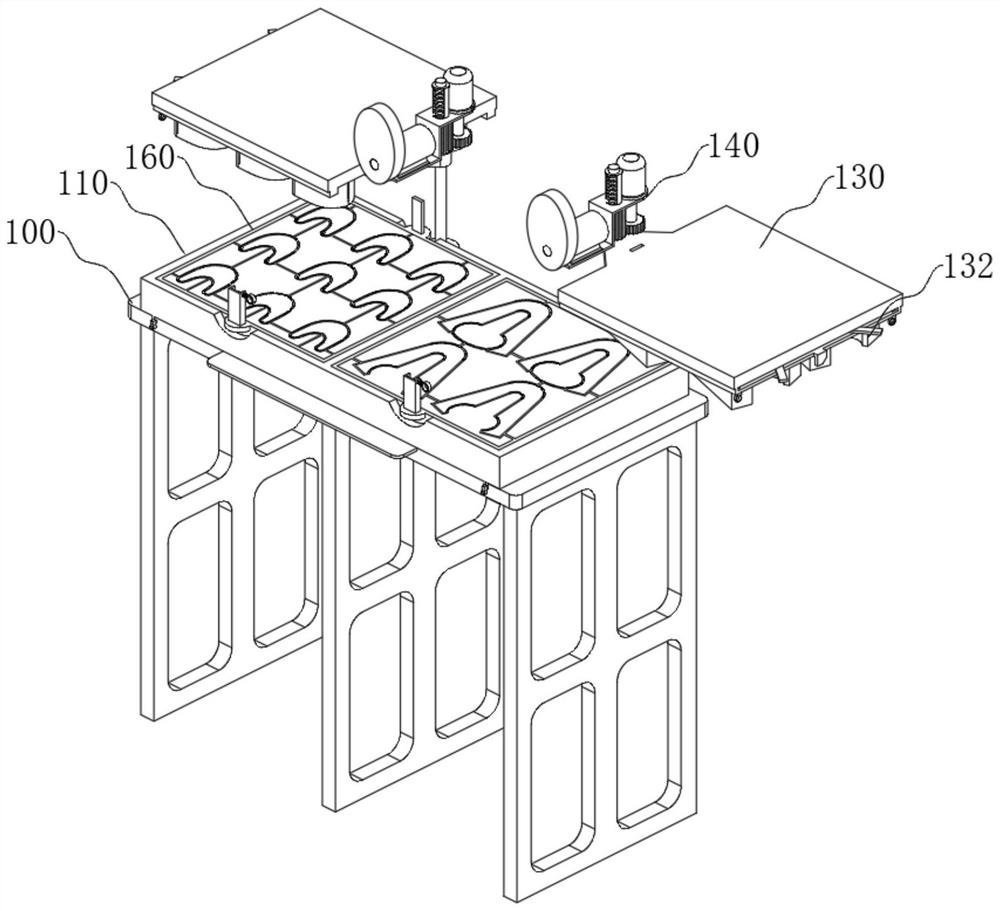

[0075] The invention provides a process for cutting synthetic leather materials for shoes, which comprises the following steps:

[0076] 1. Synthetic leather feeding stage:

[0077] S1, first place several roll materials 220 on the discharge rack 210 of the synthetic leather material cutting equipment, and mesh the transmission gear 231 with several driven gears 221 in sequence;

[0078] S2, then pull out the end of the synthetic leather material on each roll material 220, and stack it layer by layer, then start the discharge motor 230 to drive the roll material 220 to rotate, and continue to stretch several layers of synthetic leather material through the support roller 241 and the nip roller 242 until it is fully covered on the top surface of the cutting die holder 110, then stop the discharge motor 230 from working;

[0079] S3, turn the knob 244 again to drive the pressing roller 242 to move down, and then press several layers of synthetic leather materials;

[0080] Syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com