Inland river ship electric propulsion system and inland river ship navigation control method comprising same

An electric propulsion and electric system technology, applied in the directions of ship propulsion, propulsion components, propulsion engine, etc., can solve the problems of not considering the requirements of navigation control, energy waste, poor operating conditions of diesel engines, etc., to reduce the navigation resistance of ships, The effect of avoiding oil leakage and improving propulsion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

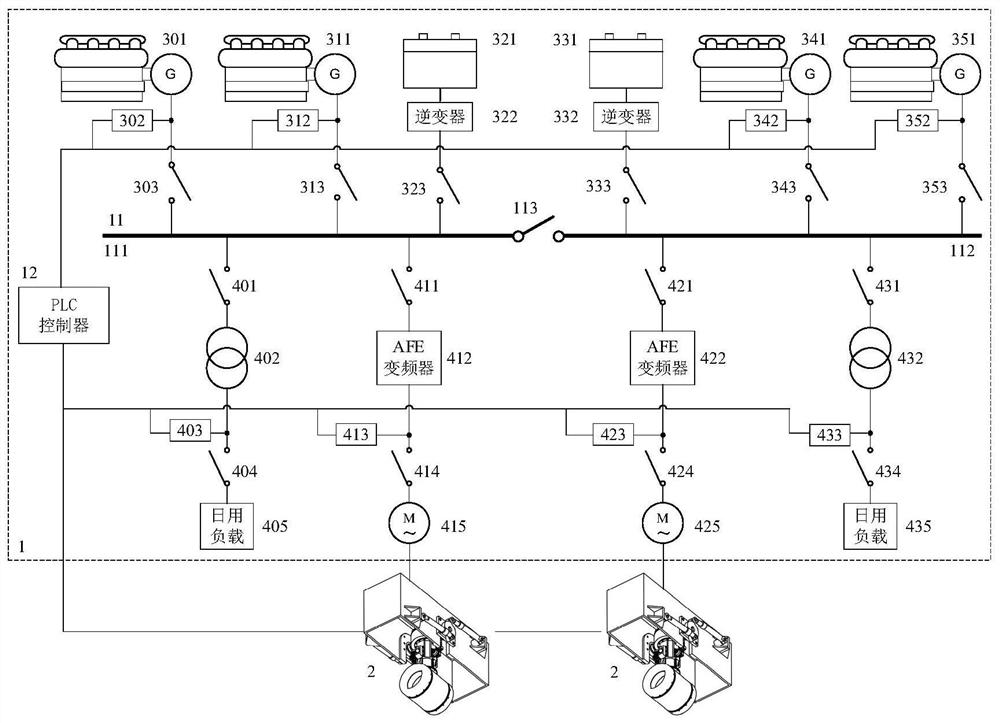

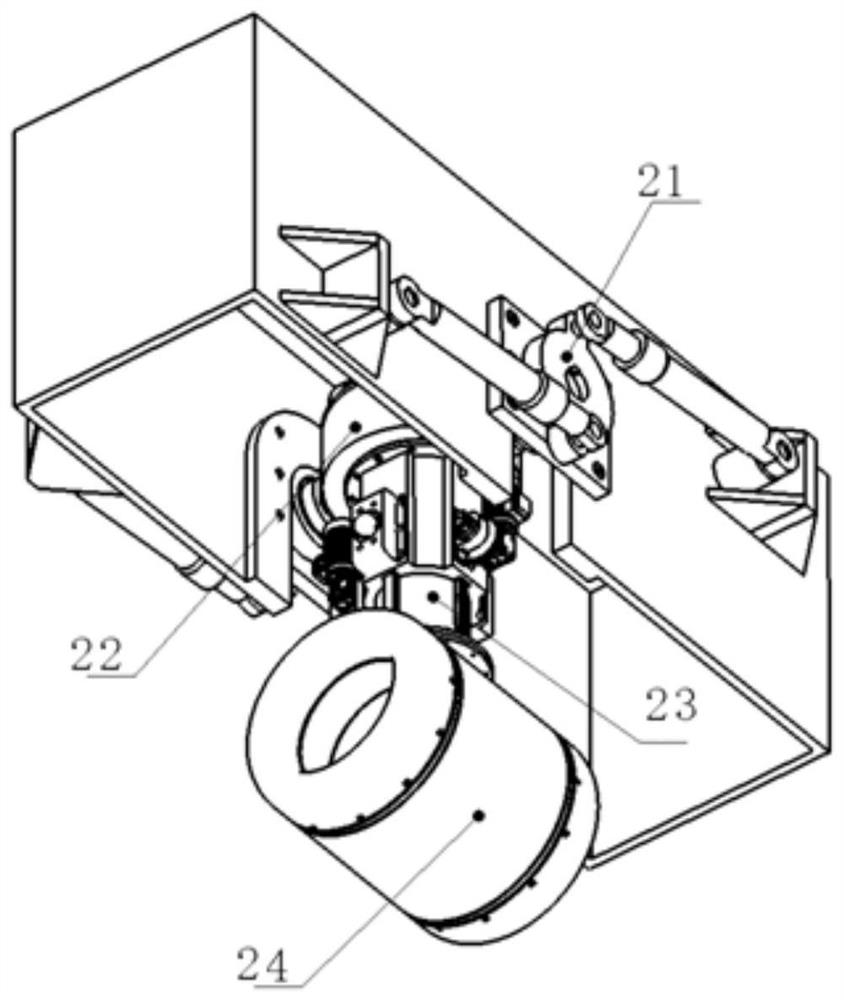

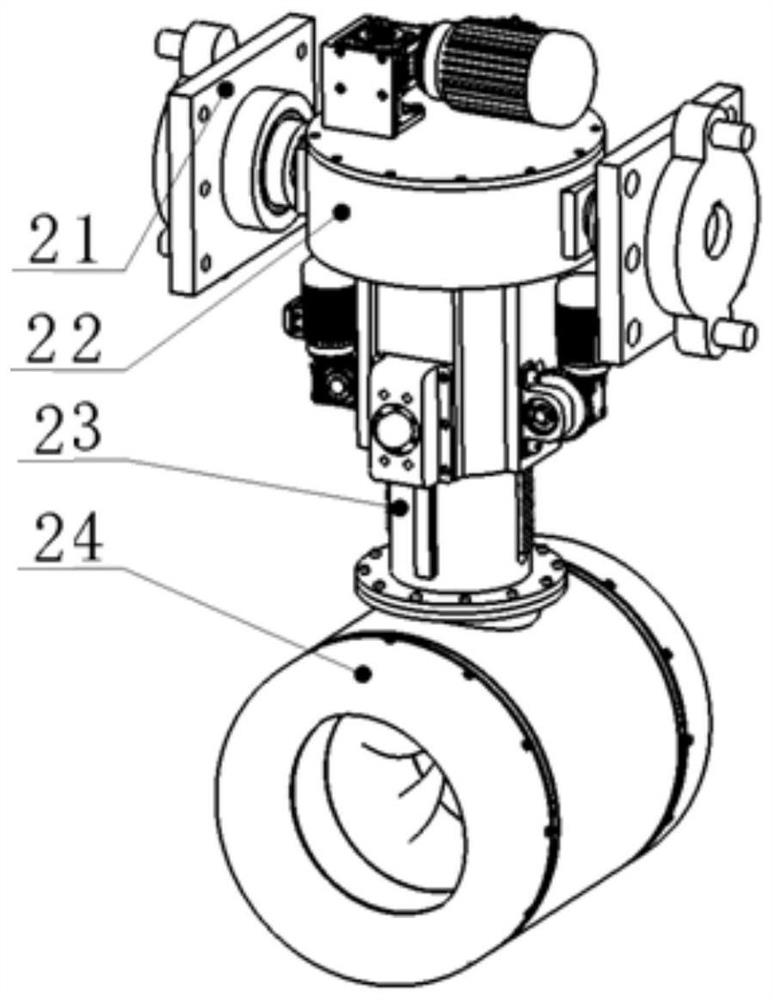

[0084] like Figure 1-12 As shown, an electric propulsion system for a river vessel includes an electric power system 1 and an azimuth propulsion system 2 that can be lifted and retracted;

[0085] The power system 1 includes two power units on the port and starboard sides. The power unit includes bus bars 111 and 112. The bus bars 111 and 112 of the two power units on the port and starboard sides are connected by a switch 113. The cables of generators 303, 313, 343 and 353 are connected with two constant speed main generators 301, 311, 341 and 351. , the first power detection modules 302, 312, 342, 352 of the output voltage and output current of 351, the first power detection modules 302, 312, 342, 352 are connected with the PLC controller 12; The cables of the inverters 322, 332 and the second circuit breakers 323, 333 are connected with sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com