Particle extrusion device for modified starch processing

An extrusion device and modified starch technology, which is applied to mixers with rotating stirring devices, transportation and packaging, and filtering and sieving, can solve the problems of general mixing effect and low extrusion efficiency, and achieve enhanced purification effect and convenience The effect of taking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

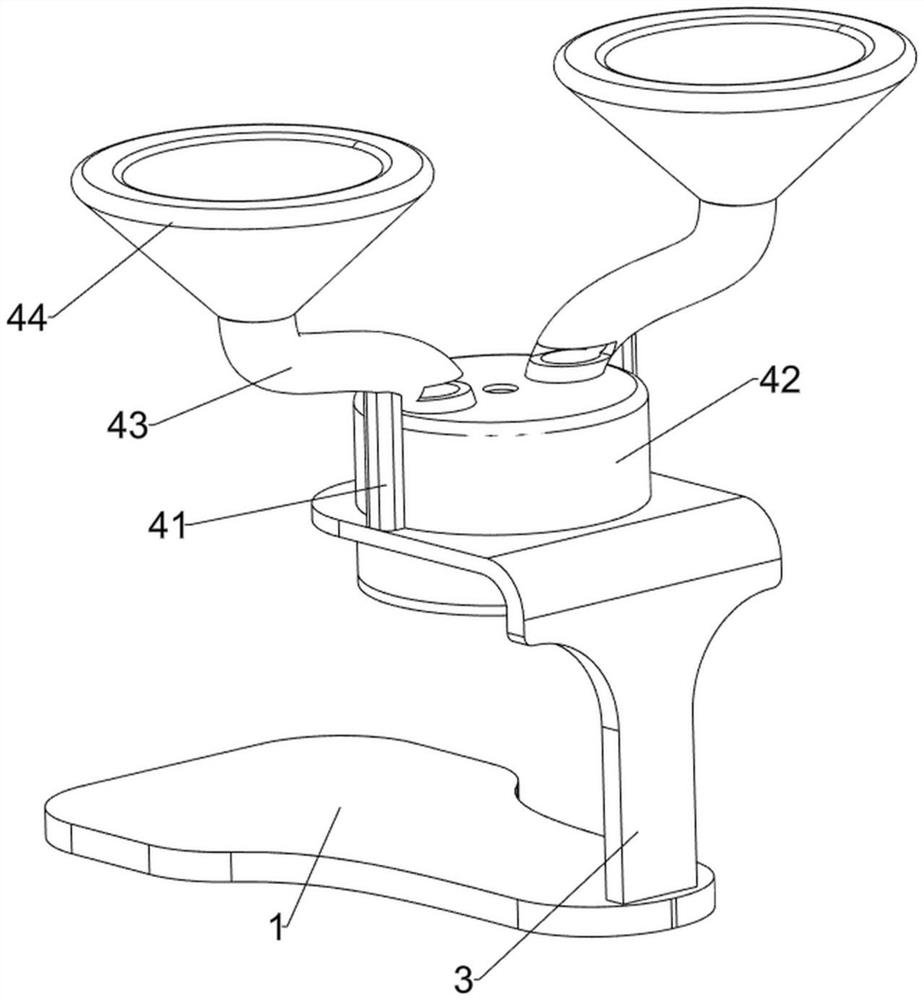

[0066] A granule extrusion device for modified starch processing, such as figure 1 As shown, it includes a base 1, a first support column 2, a support seat 3, a feeding mechanism 4, a rotating mechanism 5 and a reciprocating mechanism 6, the right side of the base 1 is provided with the first support column 2, and the right side of the base 1 is provided with a There is a support seat 3, a feeding mechanism 4 is provided on the upper part of the support seat 3, a rotating mechanism 5 is provided on the feeding mechanism 4, a reciprocating mechanism 6 is provided on the lower left side of the feeding mechanism 4, and the reciprocating mechanism 6 is slidingly connected with the rotating mechanism 5 .

[0067] When people need to extrude starch granules in the process of processing modified starch, this extrusion device can be used. First, the modified starch to be purified is put into the feeding mechanism 4, and then the rotating mechanism 5 is started. The modified starch in...

Embodiment 2

[0069] On the basis of Example 1, such as Figure 2-4 As shown, the feeding mechanism 4 includes a first fixed block 41, a stirring box 42, a feeding pipe 43 and a blanking frame 44, the top of the support seat 3 is provided with the first fixed block 41 on both sides, and the top of the support seat 3 is provided with a first fixed block 41. Stirring box 42 is arranged, and the top of the first fixed block 41 is provided with feeding pipe 43, and feeding pipe 43 is connected with stirring box 42, and feeding pipe 43 top is provided with feeding frame 44.

[0070] People will unload the modified starch to be purified from the top of the unloading frame 44, slide down into the mixing box 42 through the unloading pipe 43, and realize the effect of unloading.

[0071] Rotating mechanism 5 comprises rotating shaft 51, stirring column 52, space cam 53, motor 54 and groove block 55, and stirring box 42 top left side is provided with groove block 55, groove block 55 tops are equipped...

Embodiment 3

[0076] On the basis of Example 2, such as Figure 5-7 As shown, it also includes a blocking mechanism 7, which includes a second baffle plate 71, a first rotating block 72, a pressure rod 73, a second fixed block 74, a sliding column 75 and a spring 76, and two feeding pipes 43 bottoms are slidingly connected with a second baffle plate 71, the top of the rotating shaft 51 is provided with a first rotating block 72, the middle of the top of the mixing box 42 is provided with a second fixed block 74, and the middle part of the right side of the second baffle plate 71 is provided with a receiving block. Pressure rod 73, the pressure rod 73 cooperates with the first rotating block 72, the pressure rod 73 is slidably connected with the second fixed block 74, and a sliding column 75 is connected between the pressure rod 73 and the right side of the second fixed block 74, The sliding column 75 is slidably connected to the second fixing block 74 , and a spring 76 is wound around the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com