Ultrathin wafer processing device

A technology for processing devices and wafers, which is applied in the direction of grinding devices, metal processing equipment, manufacturing tools, etc., which can solve the problem of reduced friction between the polishing pad and the wafer, easy decrease of the surface roughness of the polishing pad, and difficulty on the side of the wafer. Fitting and fixing problems, to prevent inconsistent thickness, prevent incomplete grinding, and avoid frequent disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

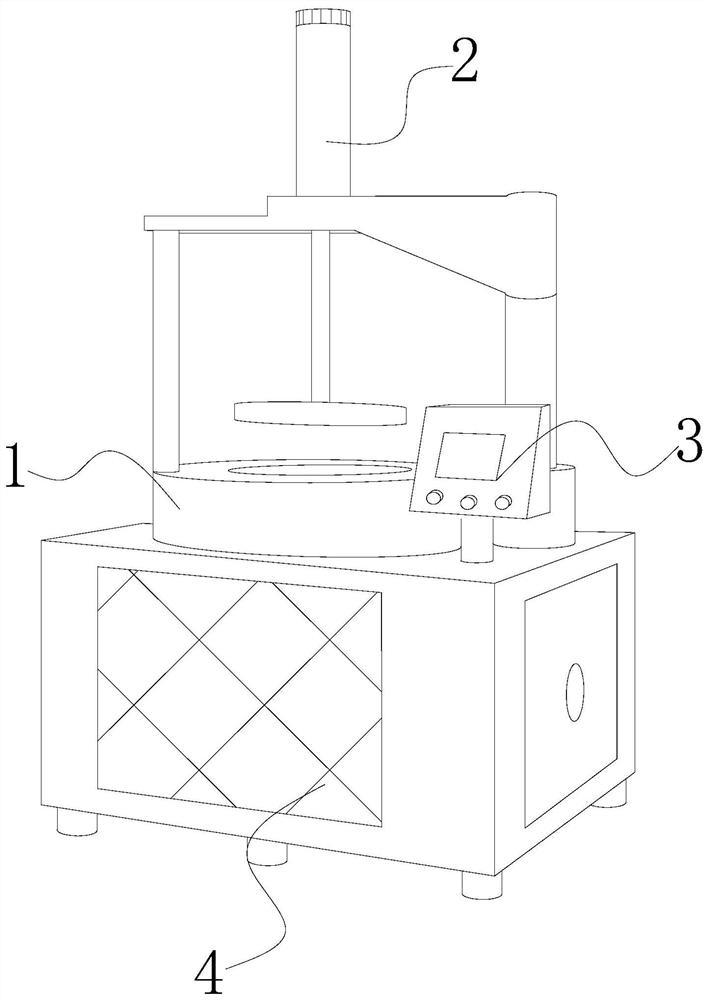

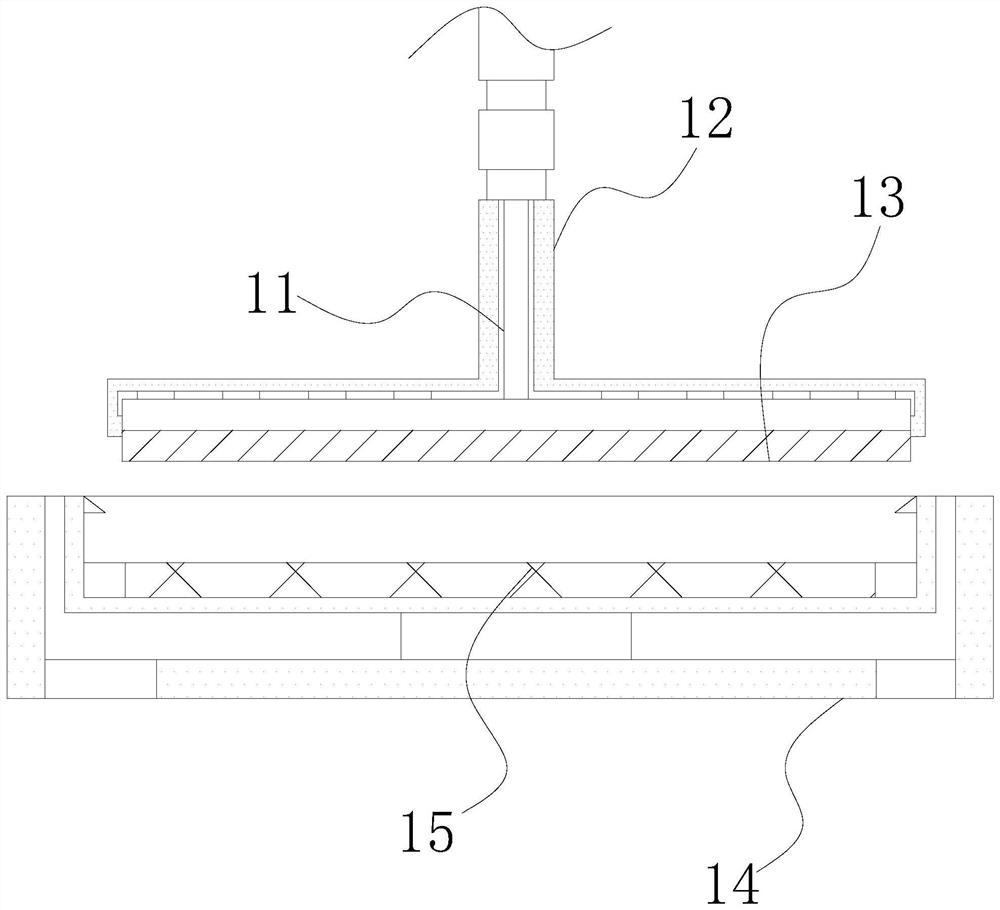

[0025] Such as Figure 1-Figure 5 Shown:

[0026] An ultra-thin wafer processing device according to the present invention, its structure includes a processing mechanism 1, a rotator 2, a control switch 3, and a workbench 4, the rotator 2 and the processing mechanism 1 are located on the same central axis, and the control switch 3 Embedded on the upper surface of the workbench 4, the processing mechanism 1 is installed on the upper end of the workbench 4, the rotator 2 is fixed on the upper end of the workbench 4, the processing mechanism 1 is provided with a fixed plate 11, a retractor 12, a grinding Structure 13, rotating plate 14, fixed structure 15, the fixed plate 11 runs through the inside of the retractor 12, the grinding structure 13 is fixedly attached to the inside of the lower end of the expander 12, and the lower end of the fixed plate 11 runs through the grinding structure 13 Inside, the fixed structure 15 and the grinding structure 13 are located on the same cen...

Embodiment 2

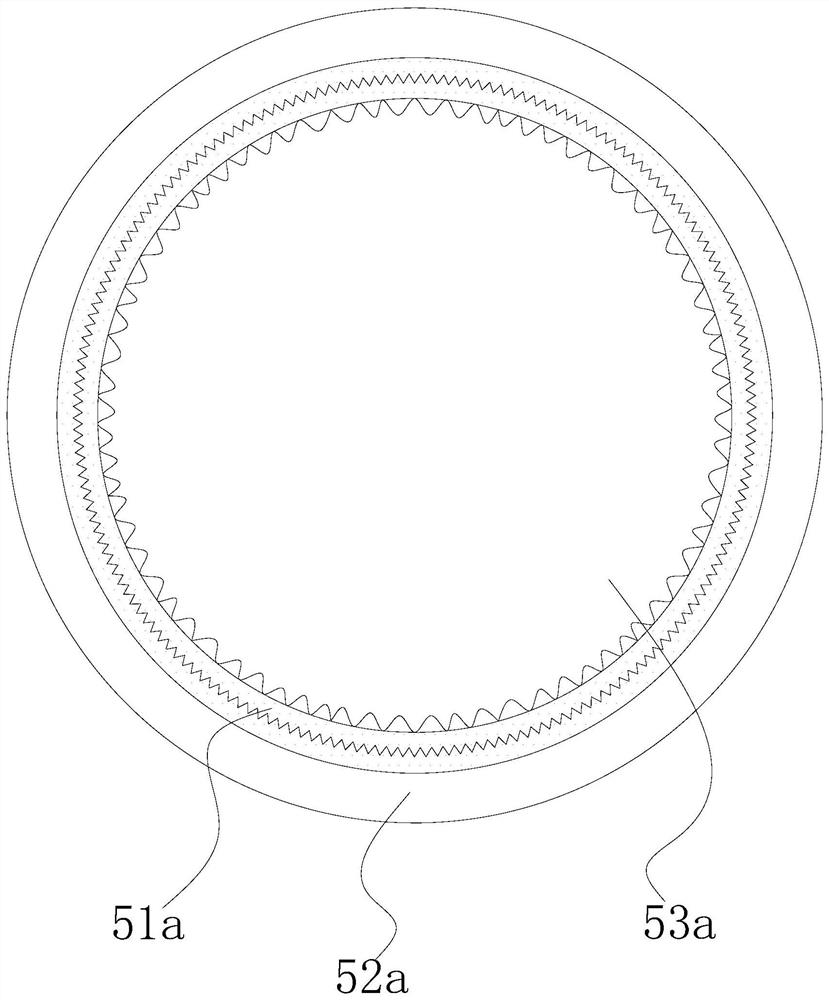

[0033] Such as Figure 6-Figure 8 Shown:

[0034]Wherein, the grinding structure 13 is provided with a grinding plate w1, a friction structure w2, an air hole w3, and a fixed ring w4, the friction structure w2 runs through the inside of the grinding plate w1, and the air holes w3 are provided with thirty The plate w1 is circularly distributed at the center point and runs through each other. The fixed ring w4 is welded on the outside of the grinding plate w1. The friction structure w2 is located on both sides of the air hole w3. The fixed ring w4 is embedded and fixed on the inner side of the lower end of the retractor 12. The friction structure w2 spreads out from the central axis of the grinding plate w1, and the diffusion becomes larger as it goes to the outside, so that the grinding plate w1 rotates to grind the wafer, and the heat generated by friction is diffused through the vent hole w3.

[0035] Wherein, the friction structure w2 is provided with a fitting plate w21, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com