Threaded connecting piece shape matching machining conversion method and device

A threaded connector and conversion device technology, which is applied in the field of threaded connector shape matching processing conversion method and device, can solve the problem of poor rigidity, cracks and edge chipping of non-metallic shell covers, and the dimensional accuracy and surface roughness of guide rail grooves cannot meet the design requirements. Requirements and other issues to achieve the effect of ensuring matching and smoothness, ensuring consistency, and uniform rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0055] Below in conjunction with accompanying drawing, enumerate a specific embodiment, comprise the steps:

[0056] Step 1, the processing of the shell cover conversion device and the shell conversion device;

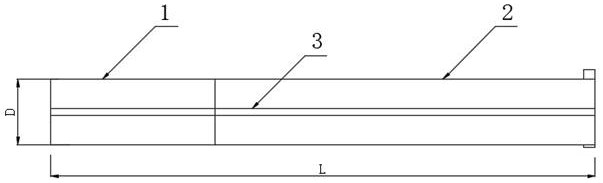

[0057] Process the shell cover conversion device and make the external thread size consistent with the shell cover, process the shell conversion device and make the internal thread size consistent with the shell;

[0058] Assemble through the external thread of the cover conversion device and the internal thread of the shell conversion device;

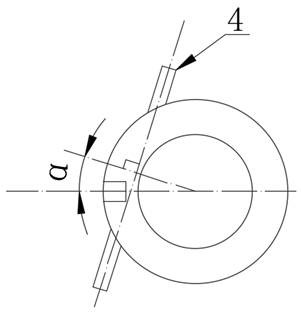

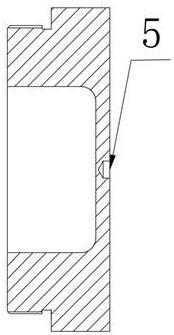

[0059] After assembly, mill the datum plane of the cover conversion device and the housing conversion device respectively, and mark four points a, b, c, and d on the datum plane according to the corresponding positional relationship during assembly (such as Figure 4 and Figure 6 shown);

[0060] Step 2, when disassembling and processing, process the circumferential guide rail groove of the shell and the circumferential gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com